Aerospace Manufacturer JPB Système Successfully Trials Metal Binder Jet 3D Printing Technology

Aerospace manufacturing firm JPB Système has recorded 80% reductions in lead times and 30% reduction in weight-savings as it trials metal binder jet (MBJ) technology for the production of flight-ready parts.

The company is trialling metal binder jet 3D printing technology in a bid to enhance the service it providers to the likes of Safran, Pratt & Whitney, GE and Rolls Royce. By leaning on the metal additive manufacturing process over the last few months, JPB Système has been aiming to achieve greater efficiency and agility across its production operations to deliver robust, lightweight and more complex parts.

With additive manufacturing, the company has been able to print moulds in four weeks that would previously have been turned around over a six-month period, while it has also facilitated the creation of test parts that utilise less material, save 30% in weight and yet still match the durability of traditional components.

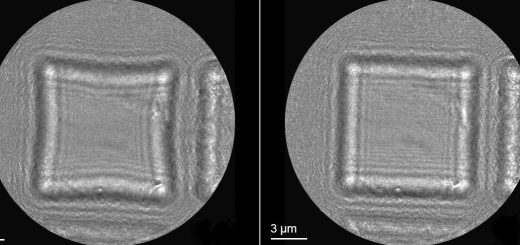

JPB Système also sees value in 3D printing’s capacity to produce 100 different parts in the same time it takes 100 identical ones; to consolidate multiple parts into one; and to develop products that accommodate one element inside of another. In one example, the company has produced an assembled multi-component functional system that incorporates three components into one, simplifying the supply chain and removing the assembly time. It is also said to be safer with the ‘eventuality of foreign object damage to the engine’ all but eliminated.

“As we anticipated, our trials of MBJ technology underscore how its versatility and ability to reduce time and costs offer huge benefits for us as a company,” commented Jocelyn Vecchio, Director of Engineering and Innovation at JPB Système. “So far, our exploration into the application possibilities of MBJ have proved very successful and offer significant potential in our quest to innovate our production processes to better meet the needs of our customers.”

In 2023, JPB Système is set to open a new state-of-the-art facility in Villaroche, France which will feature automated production lines that utilise additive manufacturing technology. The company suggests its ability to leverage additive manufacturing to develop more advanced products could increase its strategic competitiveness with new patents.

Source: tct

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments