Rapid Tooling in the Tool Making Department of OECHSLER AG

Injection molding and additive manufacturing are two central core technologies at OECHSLER. With both manufacturing processes, OECHLSER is the global market leader in various product segments – for example in the production of the Electronic Parking Brake. At the same time, OECHSLER operates one of the world’s largest polymer-based 3D printer fleets in series production. While 3D printing, which has only been established in the industry since the 1990s, has recently often been understood as a substitute for injection molding, which was developed in the 19th century, OECHSLER uses both technologies in a complementary manner.

Accordingly, OECHSLER chooses the production technology based on the specific application to be manufactured. In addition, both technologies are combined very perfectly along the value chain – for example, in rapid tooling in toolmaking.

Especially for injection molds with conformal cooling, the use of 3D printing has proven its value. With traditional (subtractive) processes the complexity of molds is limited. Also, the complexity of these processes is strongly correlated with cost and manufacturing time. 3D printing was a crucial multiplier to offer the complete package faster, cheaper, and more efficient.

![]() The challenge

The challenge

For more than 15 years, OECHSLER has been working with additively manufactured tool inserts made of metal, as these can integrate complex cavities and near-contour cooling. In 2014, we operated 3D printing for the first time ourselves in tool making – at that time for plastic inserts. In 2020, we expanded our portfolio in toolmaking and can now manufacture metal additive tool elements ourselves. Even though OECHSLER is one of the pioneers in additive manufacturing, implementing a new technology always presents challenges. For example, the size of the element and its accuracy is limited by the printer. The metal printer can achieve a part accuracy of 0.05 millimeters, which is not sufficient for injection molds in OECHSLER’s high-precision applications.

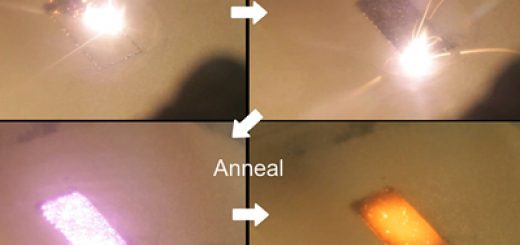

The quality of the components must also be guaranteed, and since the laser generates heat in the printer, stresses can arise in the component during printing. Depending on the application of the component, this can lead to deformation or, in the worst case, breakage.

![]() The solution

The solution

The solution is a metal printer that uses the “metal laser melting” (MLS) process. It applies a metal powder in thin layers to a building platform. A laser about one centimeter in size scans the shape given to it according to the CAD model and melts it onto the plate, or the previous layer. Each layer is about 0.04 millimeters thick. The printing process could be optimized through the existing know-how from more than 2.5 million 3D-printed parts and systems.

The printed components are post-processed after printing to achieve the required accuracy. This is achieved by classical subtractive processes. In addition, thermal tensions caused by the melting process are relieved by downstream heat treatment and the target hardness of the component is adjusted.

Sample component with helical cooling made of tool steel MS-1

Sample component with helical cooling made of tool steel MS-1

Sample component with various geometry structures and cavities made of stainless steel 17-4PH

Sample component with various geometry structures and cavities made of stainless steel 17-4PH

![]() Outcome

Outcome

OECHSLER utilizes the MLS printer to produce a wide variety of complex elements of molds itself without any additional time or costs. Here, the combination of additive and subtractive processes, in particular, is decisive for the required accuracy of the component. With the help of 3D-printed molds, enable the development of prototypes for injection molding much faster and more cost-effectively.

This is an important lever, especially for the realization of shorter development cycles. Tailored to the order, OECHSLER offers its customers to produce corresponding 3D-printed tool parts in-house. From the original intended application of the MLS printer for shoe soles and bicycle saddle molds, the field of application has now expanded to large-scale use in the area of injection molds.

Source: OECHSLER

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments