IDS Trade Show: TRUMPF Presents Solution for More Efficient Abutment Printing

September 22, 2021, At IDS dental show, high-technology company TRUMPF unveiled a new processing solution that makes the production of customized, implant-supported dental prostheses more efficient. The new process focuses on the manufacturing of “abutments”, the connecting elements that join the dental implant to the visible crown. The TRUMPF TruPrint 1000 3D printer, which is specially designed for the dental industry, can print up to 64 implant abutments in a single print job – and thanks to the use of preforms it gets the whole job done in less than three hours! A preform is a special kind of base or substrate with a prefabricated implant connection geometry and a flat platform on which an individual component can be printed from a chromium-cobalt alloy or titanium using a 3D printer. This processing solution is used to create the abutments that are ultimately used to support the dental crown. Abutment manufacturing has traditionally relied on milling, bonded hybrid Abutments, or complex casting methods. But the new TRUMPF preform solution makes the whole fabrication process more efficient while using fewer materials. “Implant-supported dental prostheses are the world’s fastest-growing dental industry segment,” says Reinhard Sroka, dental industry manager at TRUMPF. “That’s why dental laboratories need to act fast to tap into this lucrative and pioneering field – harnessing the power of high-productivity 3D printers is the best way to tackle growing cost and competitive pressures.”

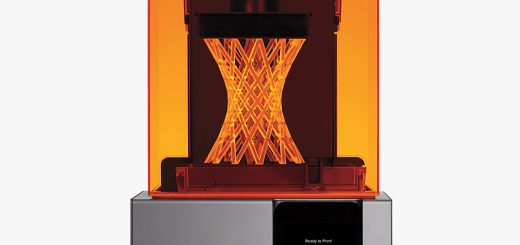

TRUMPF has developed a special adapter plate for its preform processing solution; this can be loaded with preforms prior to printing and inserted into the TruPrint 1000 3D printer, where it is calibrated fully automatically. The printer, which comes with a choice of one or two lasers, uses the laser metal fusion technique to melt the metal powder layer by layer and fabricate individual abutments in the powder bed.

![]() A versatile choice for implant prosthetics

A versatile choice for implant prosthetics

As well as boosting productivity, additive manufacturing also offers key benefits when it comes to tackling complex abutment geometries. Users have almost unlimited freedom to choose where to position the screw channels, and even the most complex structures can be fabricated with ease.

The new TRUMPF preform processing solution adds an extra dimension to the TruPrint 1000, making it the perfect all-in-one machine for implant prosthetics manufacturing. What’s more, the Multiplate option enables the system to produce parts without manual intervention on up to four build platforms, paving the way for overnight and weekend work. The system automatically switches to the next platform after each production job and stores them directly within the machine. The Multiplate function cannot currently be used in tandem with the new preform processing solution. Additive manufacturing of custom abutments is now available for all new TruPrint 1000 machines. This function can also be retrofitted to the latest series of machines.

Source: TRUMPF

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments