Growing the Customized Medical Implant Market with Electron Beam Melting

The orthopedic industry continues to amaze us daily as it expands the boundaries of additive. As more healthcare professionals—not just in orthopedics—discover the technology’s potential to 3D print custom implants, devices and instruments, we anticipate additive-medical collaborations becoming more commonplace and increasingly closer to the patient on hospital campuses.

In this article, we discuss how Electron Beam Melting (EBM) and emerging or evolving materials are fast becoming the technology of choice across the medical implants and devices sector.

The term “customized” commonly refers to tailoring the geometry of each medical implant to precisely fit the end patient. But customized can also be extended to include the “inside” of an implant, that is, the adaptation of the properties or function of the implant. This extended area of customization is something that is expected to grow in the coming years.

Custom-made acetabular component 100% designed and produced by Adler Ortho using GE Additive Arcam EBM machines.

Image courtesy of Adler Ortho

![]() EBM Materials and Medical Applications

EBM Materials and Medical Applications

There are already several materials that can be 3D printed—based around existing implant materials such as stainless steel, Ti-6Al-4V (Ti64) and cobalt chrome—and these materials can be customized in several different ways to suit each individual patient.

Because 3D printing offers a way of creating tailor-made implants, the time and expense to get new materials certified is a less desirable option over customizing existing materials. The change in the future will be to use the same approved material but tailor the material microstructure with that behavior of the application.

Ti64 remains one of the common material choices for our medical customers, because it offers additive users flexibility. One potential in the future is to create different microstructures, enabling the alloy to become robust for some implants and applications, while being softer and expandable for others, such as spinal cages.

Cobalt chrome is another “workhorse” alloy still in demand for implants, especially for femoral knee components and dual-mobility hip cups, as there currently are still no other materials clinically available that mirror its properties. While both cobalt chrome and Ti64 are well-suited for EBM, not all patients are candidates for cobalt chrome implants.

Another implant material that is being used is stainless steel for bone plates (as well as surgical tools). However, while it is possible to create these implants with EBM, you need to perform an extra surface finish step to obtain a suitable product. Therefore, it is a material that typically has more success with our Direct Metal Laser Melting (DMLM) technology.

![]() The Customizable Solution for the Medical Implant Market

The Customizable Solution for the Medical Implant Market

Even though there are restrictions as to which materials can be used in an in-vivo clinical setting, customizing existing materials to fit the patient can bring about enhanced functionalities compared to off-the-shelf implants.

This can take the form of a polished or rough surface, as well as different microstructures that tailor the structural properties of the implant. The ability to create implants that can fit the exact need of every patient with existing (and clinically approved) materials can also help reduce the time and cost associated with finding new clinically suitable materials to fit all surgical scenarios.

The manufacture of bespoke medical implants using EBM has already come a long way since its inception. When the process was first trialed, the coating on the surface of implants was replaced with an additively created lattice.

Today, surgeons and medical-device designers are looking to take previous implant products that they have used in the past, redesign them from the ground up, make them more functional and tailor the specific properties to the needs of the patient. As far as customization goes, the ability to create bespoke parts on a case-by-case basis is one of the most advanced levels of customization that can be achieved.

When it comes to customizing an implant with EBM, there are typically two approaches that can be taken.

Firstly, optimize the properties of the implant by changing the chemistry of the material so that it will still be within the desired specifications but with an enhanced performance. We anticipate that in the future this will be done by tweaking the microstructure of the part or by changing the process parameters during the print so a different chemical makeup can be achieved. This approach can enable the same material to be tailored with properties at both ends of the spectrum. An example is ductile properties or harder, fatigue-resistant properties, as well parts that have multi-functionalities.

Secondly, take a conventionally manufactured product and add uniqueness to it, which we expect to be more commonplace in the future. This could lead to consolidation of several different implant components being printed into a single implant, without the need for combining them during surgery. It is an approach that is already being successfully deployed in the aerospace industry where hundreds of parts are being distilled into just a few. It is an approach that will most likely filter over to the medical device sector in the coming years.

The ability to customize an implant to fit the specific needs of each patient will not only lead to fewer repairing surgeries being performed later in life but will also provide less discomfort for the patient at the point of surgery—which will lead to shorter hospital stays. On a macro level, customizing implants for each patient not only helps to provide a better surgical experience for the patient but can also save money.

Custom-made acetabular components 100% designed and produced by Adler Ortho using GE Additive Arcam EBM machines.

Custom-made acetabular components 100% designed and produced by Adler Ortho using GE Additive Arcam EBM machines.

Images courtesy of Adler Ortho

![]() A Need for Speed

A Need for Speed

The time taken from the initial diagnosis to the surgeon being able to insert the implant into a patient can be crucial. Aside from enabling designers to customize an implant, EBM offers a way to reduce the time it takes for the surgeon to receive the implant. One of the main reasons for choosing EBM over other additive technologies is because the first-time yield on the printed part is higher, and this becomes more important when the delivery time of a part is short. The overall time taken from the digital surgical planning phase, based on the actual CT scan data of the patient and the CAD drawing of the bespoke implant, to the start of printing and eventually a finished product will then be reduced.

Other additive technologies, such as laser-based modalities, have their place in the medical implant sector, but the multiple prints and iteration loops sometimes required to produce a finished part mean that they are not as suitable when time is a key driving factor.

Beyond the shorter printing times, another advantage of EBM is that it is possible to push more requirements onto the initial print, reducing the need for post-processing steps after the implant has been created.

Using EBM also significantly reduces the number of supports required during the print, which means less time is spent on support removal and a reduced area that needs to be machined, which saves time. Parts can be produced with a shorter lead time and at a much lower cost because they do not need to be sent to and from a machining shop.

Since many post-processing steps can take a long time (especially when transportation time is also factored in), the desire to post-process or spend longer times printing needs to be determined on an application-by-application basis. That will often be dependent on the other equipment that is available as well.

The time it takes for a surgeon to receive an implant could also be shortened further in the future if enough surgeons become comfortable with EBM (and metal 3D printing in general). It could enable the machines to be moved “in-house” into hospitals, so there is less time spent waiting for finished implants to arrive.

![]() Educating Surgeons on the Potential of Additive

Educating Surgeons on the Potential of Additive

We have detailed the benefits associated with EBM (and additive in general) when it comes to creating tailored medical implants. However, while this is a great advancement, it is no good if surgeons and other medical professionals are not made aware of these technologies and the potential to transform implant surgeries. While some surgeons are aware about the possibilities of additive, many are not. This is often the case with any new technology (or advanced material for that matter), and it will take time to change the status quo.

Today, a lot of the interest comes from the additive machine buyers who propose implant ideas to surgeons. Something like this, which has clinical implications, is a joint effort. While implant makers should continue to show interest, there also needs to be more collective dialogue among the additive machine and system makers, our medical sector customers and surgeons to impart knowledge and needs that will benefit all parties. If more surgeons are aware of the potential of additive, there will be multiple parties involved in generating ideas. This is how innovation loops occur, which could be harnessed to generate higher levels of adoption across the medical implant space.

![]() How the Additive Manufacturing Industry Can Help Clinicians

How the Additive Manufacturing Industry Can Help Clinicians

Many of the companies involved with creating implants, and the surgeons performing procedures with custom implants, are often aware about what they want, but not necessarily how to make it a reality.

This is where a closer relationship among surgeons, designers and additive machine makers can help those who want to use metal 3D-printed implants but don’t necessarily know where to start or where to focus their efforts. This collaboration is even more important than in other applications because of the high degree of customization required with bespoke implants. From our experience, some users may get lost down rabbit holes trying to understand how to use EBM.

In a conventional, mass-production manufacturing setting, there are validated tests that help to categorize the properties of different implants. However, the custom nature of individual implants—and the short lead times required to get the implant into the patient—means that the production process must be validated to accommodate for every variation of the custom implant, rather than relying on a part-by-part testing construct.

Having a validated process window makes it possible to print these different variations of an application with confidence without testing the actual part. Additive experts are now working on statistical process controls, which will be able to help surgeons create parts for different scenarios—whether it is for a quick production or an optimized process.

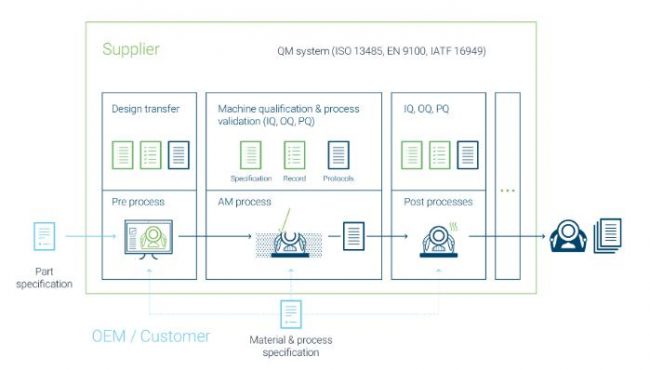

At GE Additive in Sweden, the team can assist with developing a series of IQ OQ PQ controls for the additive manufacturing process (Figure 1) to create a manufacturing framework that can be used to optimally create parts (from a machine, system, and process perspective). This validation service provides a starting point in the validation journey and focuses on supporting customers in the IQ and OQ validation phase—also known as equipment qualification controls. The implant manufacturer dictates the requirements for the part itself and all aspects of the production qualification of the part.

(Figure 1): DQ, IQ, OQ, PQ qualification flow

(Figure 1): DQ, IQ, OQ, PQ qualification flow

While additive experts cannot address clinical performance of additively manufactured parts, the individual properties and material performance of each part can be consistent. Having collaboration among all parties will be critical in getting the right frameworks in place.

(Figure 2): AMPOWER’s overview of IQ, OQ, PQ.

(Figure 2): AMPOWER’s overview of IQ, OQ, PQ.

Schematic courtesy of AMPOWER

Given that machine OEMs’ engineers work with the machines daily, it is worthwhile for any medical professional looking to create custom implants to have dialogue with these engineers, as they are the best people to inform you on how to get the best out of your machine.

This dialogue works both ways. Not only do medical professionals get insights on machine performance, the engineers creating the machines also gain more insights into how best to optimize the machines for use in medical applications and provide a better service to the medical sector.

![]() Avoiding Rabbit Holes

Avoiding Rabbit Holes

When a relatively new technology is introduced to a sector, there are often pitfalls that can be avoided. In the excitement of trying to bring metal additive to new sectors, many customers can fall down rabbit holes that provide no value and only take up time and resources. The ability to get distracted often stems from new sectors not trusting the metal 3D-printing process fully (because it is relatively new), which leads to them unnecessarily undertaking their own validation steps in every aspect of the print.

It can be daunting for first-time metal additive users, and it can be difficult knowing where to start. Questions we often encounter include “Which metal powder should I select given the choice on offer?” “How many times can I recycle or blend the powder?” and “What might the effect of recycling have on the finished part?”

These are many of the powder areas where people can spend (and have spent) a lot of time. Beyond the powder, customers can also lose a lot of time trying to get the optimal “cleanliness” of the part. Therefore, joint collaborations are often the best way to save time and money relative to these issues, as there are people who have the experience to help you.

By speaking and working with the machine OEM’s technical experts, customers can gain the best possible advice about optimizing their machines, which could prevent spending years (and money) on testing unnecessary parameters.

![]() Conclusion

Conclusion

With over 100 EBM machines in use across the medical sector, there is untapped potential for the technology in the customized implant space. Results are already being showcased in clinical settings. Going forward, for this approach to have a wide-ranging impact, there needs to be more interaction among surgeons, designers, and the additive machine makers, as this will not only foster new ideas but could help clinicians as they consider moving their metal 3D-printing operations in-house.

Additive manufacturing companies are always on hand to guide medical professionals about the use of additive machines. However, input from the medical side is critical to better understand the clinical side of the parts and expand the opportunities and applications in the medical sector.

Additive manufacturing, and in particular EBM, continues to offer many benefits for medical implant manufacturers, and the entire ecosystem coming together is going to help drive the innovation of additive in the wider medical space even further.

Source: GE

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments