Anisoprint And Additive Flow Launch Topology Optimization Software for Composite Materials Design

Anisoprint, a Luxembourg-based composite 3D printing startup, and Additive Flow, a British AM software developer, now offer a full-scale CAE tool compatible with Aura, Anisoprint’s slicing software for composite 3D printing. The software will enable users to optimize geometry smoothly through all phases of the design process. The beta version will be released in October.

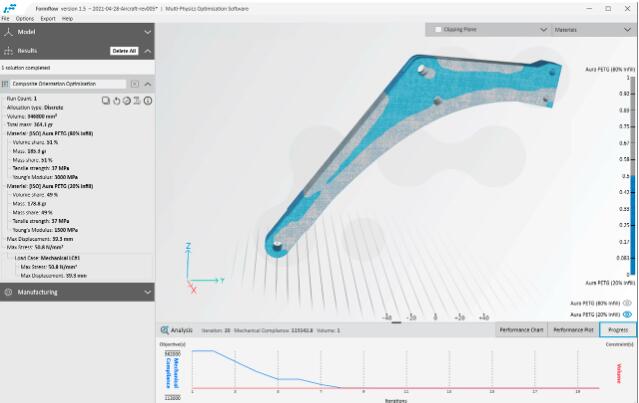

Physics simulation and the resulting design by formflow

Physics simulation and the resulting design by formflow

“Design for Additive Manufacturing (DfAM) is one of the hottest topics. Not only because different additive manufacturing technologies require a specific approach for design, but they make designs that were impossible before possible now. As technology developers, we need to offer our customers tools and a smooth workflow for DfAM, that will help to get the most out of the unique hardware and material capabilities our solutions provide,” said Fedor Antonov, CEO of Anisoprint. “We are happy to find partners with whom we can shortcut the long and difficult R&D cycle of developing a DfAM solution, fully capable to support Anisoprinting. And it is already available for users within a simple workflow and native integration of our software products – Formflow and Aura 2.4.”

Composites offer many benefits in R&D and production applications, but costs are an issue. The key to making the most of composites is their versatility. Composite fiber, being an anisotropic material, exhibits different properties in different directions. Effectively using these characteristics can result in a 20-fold increase in mechanical parameters, such as stiffness.

“Our accessible UI provides an integrated workflow to exploit material property <> parameter relationships, and allow these to be efficiently applied through repeatable workflows. Results selection is made simple with visualization comparison tools – and streamlined export with build-file formats, including Aura,” said Alexander Pluke, Additive Flow CEO. “We’re excited to be working with Anisoprint and their enhanced multi-property capability that can deposit different materials, and tune anisotropic properties to meet specific strengths and engineering requirements.”

![]() Optimizing composite materials brings significant cost and application benefits

Optimizing composite materials brings significant cost and application benefits

Even though continuous composite 3D printing is an automated technology, it still requires extensive expertise to design anisotropic structures, specifically for fiber paths, load simulation patterns, calculating thermal exposure, weight, and many other tasks. Inconveniently, such tasks can only be performed by professionals with structural performance of materials expertise. Additive Flow addresses this challenge with their software Formflow – a specific CAE (Computer-Aided Engineering) tool for performance analysis and structural anisotropic design that will result in the most effective topology for given parameters.

Formflow will not only add another tempting feature, but provide a boost for all the advantages of anisoprinting technology and unleash the potential of anisotropic structures.

Cost savings will become more tangible:

- Developing designs with anisotropic structures is now automated and precise.

- Even faster prototyping with AI-driven computation and optimization. The trial and error method will now be replaced by physics simulating algorithms that define optimally performing parts. Their predictive capability has earned a reputation as an essential verification, troubleshooting, and analysis tool.

- Optimized material use: parts designs with minimal weight and maximal desired parameters lead to reasonable and efficient material consumption.

- The advanced software takes care of the topology, so printing involves less manual input leaving the specialists free for other work.

- Improved flexibility due to clear quantitative analysis of loads.

![]() The devil is in the detail: effective design for optimal performance

The devil is in the detail: effective design for optimal performance

The behavior of composite materials, that in a broad sense are a novelty for industrial production, is difficult to predict. Structural behavior, thermal behavior, fatigue behavior, flexural strength, or any other parameter require dedicated modeling.

In addition, manufacturing complexities are such that novice users run the risk of manufacturing a product that unexpectedly turns out to be different from the one that was designed.

It is paramount to achieve optimization goals within a set of pre-determined constraints with reliable — and compatible — tools and technologies developed to work together.

Formflow is now designed to export files compatible with the Anisoprint proprietary slicer — Aura, thus facilitating advanced materials design. Users do not need to know the geometry of the model to achieve their goals, only the target parameters. Thermal resistance, strength, stiffness, weight, sustainability, and even time and cost of production are parameters that can be mapped in Formflow to calculate the optimal shapes and properties and supplemented with detailed graphs, showing clear dependencies between competing parameters such as mass and displacement and highlighting the most favourable trade-off. Once the model is optimized, it is fed to Aura to prepare for printing

![]() See how time and cost vary with mechanical properties

See how time and cost vary with mechanical properties

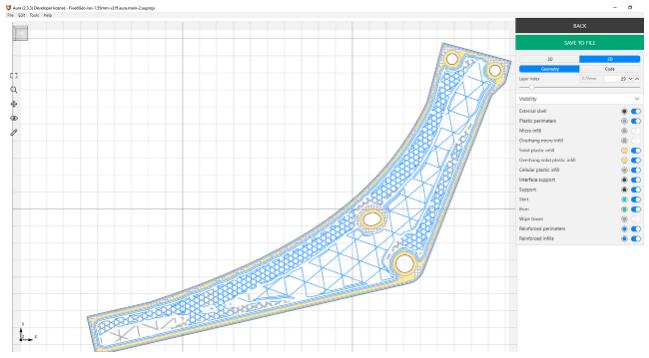

We conducted a testing for optimization of internal structure of a continuous fiber reinforced part. Below you can see an aircraft chair support layer by layer designed to be light weight and withstand sufficient loads.

Reinforcement pattern exported from formflow to Aura

Reinforcement pattern exported from formflow to Aura

The darker areas indicate a more dense lattice that reinforces the most loaded regions.

Naturally, the more dispersed grid here fills the areas that carry less load: thus we do not waste material by over-reinforcing them. Using the optimal amount of material leads to reducing printing time, less material waste and reduced costs.

It is peculiar how a simplistic detail starts to resemble natural structures once we see how boundary conditions really work. The sophisticated pattern of lattices (they function as multimaterial here) gives an exhaustive reason why we need reliable software for composite materials design to make the most of continuous fiber 3D printing.

Source: anisoprint

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments