Croom Medical Surges Ahead With Cutting-Edge Additive Manufacturing Technology

Croom Medical has produced over 20,000 Additive Implants as of September 2021 at its Additive Manufacturing center of excellence. The company has invested over €10.2million in its plant and machinery over the past 24 months alone where additive manufacturing is a key pillar for the company’s technology driven strategy.

As an industry leader in utilizing high-tech, high-growth, cutting-edge medical device manufacturing technology, Croom Medical has over 37 years’ experience in partnering with global healthcare companies as an outsourced manufacturing service of high precision components and medical devices. Founded in 1984, Croom Medical’s quality team has been paramount to the recent success of multiple 510k submissions hosting additive implants on behalf of its global customer base.

‘’We started our metallic additive journey in 2008 where we aligned ourselves with industry and academic partners. The strategic technology driver for our business here was the market intelligence gained by our research, development and innovation (RDI) team. Our RDI and Quality team have really been the backbone to this technology success for us here in Croom. They have consistently gone above and beyond in collaborating with our OEM customer base on developing a cost competitive additive manufacturing process that meets all morphological, chemistry and mechanical ASTM standards. We have recently invested in an in-house metallurgical lab that will add further value to our operations. With a number of powder bed fusion systems on site, we are looking at EBM and heat treatment processes which will further augment our value add in 2022.’’ Patrick Byrnes, CEO at Croom Medical.

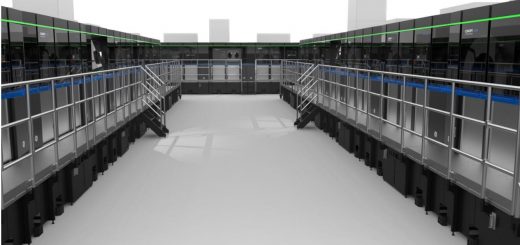

Croom Medical hosts a skilled team of 80 who are steeped in the advanced machining and manufacture of orthopedic implants and instruments. Aside from lights out 5-Axis Machining and a number of sliding heads, the company has also invested over €1.6million in a state of the art drag finishing system for its implant production. In addition, Croom Medical hosts nondestructive testing, 5-Axis CNC Grinding, Intermediate Clean Lines, Hand Finishing Cells, Heat Treatment, Metrology Lab and Toolroom capabilities.

Source: Orthospine news

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments