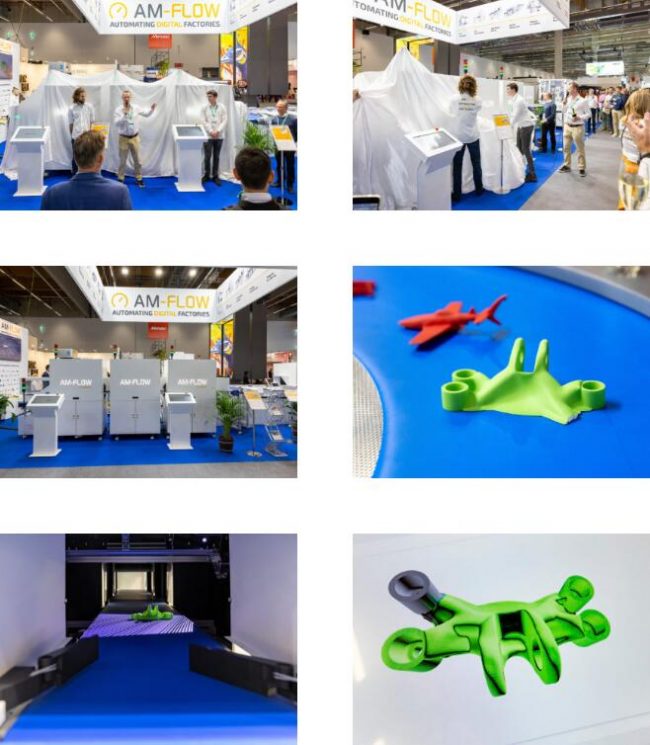

AM-Flow launches world’s first AM In-Line Quality Control solution at Formnext 2022

As the AM industry morphs from prototyping to high quality manufacturing, Dutch workflow automation company AM-Flow launches the world’s first AM In-Line Quality Control solution at Formnext 2022.

The AM-QUALITY production line enables quality control of each, and every part produced in 3D print factories, at an unprecedented high processing speed. 100% quality control, at a cycle-time of 10 seconds per part, with a resolution of 50 Microns. The AM-QUALITY identifies issues such as breakages, warping, surface defects, etc thus enabling early detection and addressing of sub-quality prints, immediately during production.

The AM QUALITY ensures the highest quality standards and enables certification – for example for the medical, automotive and aviation industry – while slashing the cost per part of quality control from tens of dollars to only cents.

“We’re extremely happy to announce the launch of the AM-QUALITY. Our perspective has always been to provide industrial solutions to the AM industry, setting industry standards, to help it scale and deliver on AM’s core benefits. Together with our part identification, sorting, bagging, transport, and bin-picking modules, AM-QUALITY, as the latest member of the AM-Flow family of solutions, will help scale the AM industry and increasingly be the manufacturing technology of choice for more and more applications”, according to Stefan Rink, CEO AM-Flow.

Supported by AM-Flow’s proprietary middleware software platform, AM-LOGICTM, the AM-QUALITY feeds all generated data back to the MES system of clients, enabling immediate reprints when necessary and optimizing setting parameters of the 3D printers and post-production equipment, creating a true Industry 4.0 AM industry.

Source: AM-Flow

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments