Additive Manufacturing is Pushing More Companies to Tap into Cloud and High-performance Computing Resources

Although additive manufacturing offers clear advantages in many manufacturing applications, current design and simulation resources may be challenged by the complex computational fluid dynamics simulations and shape optimization processes required. Cloud and high-performance computing resources can help companies take better advantage of new design possibilities enabled by 3D printing without requiring a costly investment in new compute resources.

3D print designs that can be simulated and optimized in an HPC environment (on-premise or, increasingly, in the cloud) will be a key enabler of digital manufacturing applications. A number of simulation software vendors, for example, have been working to allow their solutions to run simulations on the Microsoft Azure Big Compute platform.

Cloud resources are increasingly used for simulation and optimization purposes as designs become more complex, and models increase in size, requiring more multiphysics simulation work. For example, Utah-based Optisys creates 3D-printed radiofrequency (RF) antennas. The company uses ANSYS HFSS and Mechanical simulation tools on Rescale’s cloud-based HPC infrastructure. Rather than tying up local computers for hours, the company can run advanced simulations in just a few minutes.

To take advantage of the possibilities of design for additive manufacturing, companies increasingly need to leverage faster, graphics processing unit-based resources on their workstations and cloud-based HPC for simulation.

“We are at a unique point in time where the manufacturing hardware has outpaced the software,” says Harshil Goel, founder and CEO of Dyndrite, which has developed a solution to streamline CAD-to-print processes.

![]() Computing Options Evolve

Computing Options Evolve

Although concerns about IP and security have held back cloud adoption in some sectors, an increasing number of companies are more comfortable with using cloud resources for AM applications. “There’s been some reluctance around CAD in the cloud because of a misperception about security,” says Brent Stucker, director of additive manufacturing at ANSYS. “On the flip side, users really want to take advantage of the geometric complexity that additive has to offer, so those concerns about security are being outweighed by this advantage of running 1,000 design points or 1,000 different options on a part without having to buy a bunch of hardware. That is pushing them toward cloud and HPC resources.”

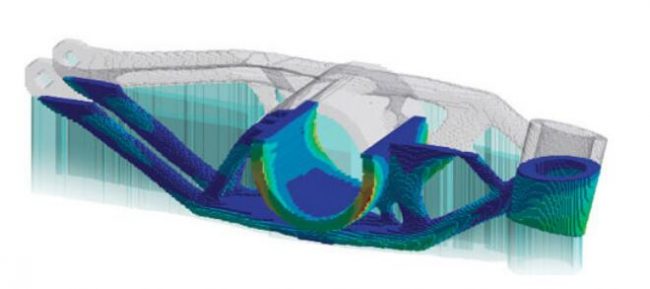

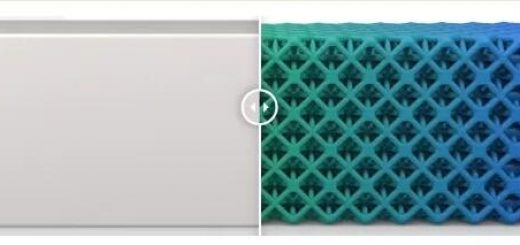

Additive solutions like those from ANSYS can reduce the number of failed builds and allow users to explore materials and optimal machine parameters. Image courtesy of ANSYS.

Additive solutions like those from ANSYS can reduce the number of failed builds and allow users to explore materials and optimal machine parameters. Image courtesy of ANSYS.

The use of multiphysics in AM is pushing some of this activity. “With parts consolidation in additive, there is a huge push to create these large assemblies with fewer components, and those assemblies are responsible for achieving a lot of different physics goals. That can be computationally intensive. That ties up a lot of hardware that you don’t want to buy locally, which is driving the use of cloud-based HPC resources,” Stucker says.

![]() Design, Simulation Tools Adapt

Design, Simulation Tools Adapt

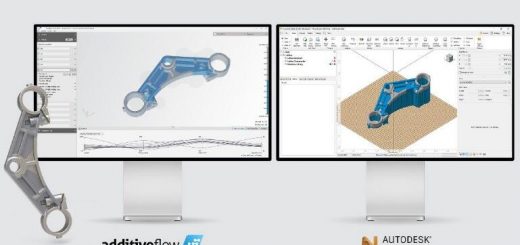

Software providers are developing new ways for CAD and simulation tools to help accelerate their performance for additive manufacturing applications. Those strategies include leveraging cloud-based access to tools and computing resources, as well as taking advantage of modern GPU capabilities. ANSYS, for example, launched a major initiative to enable all of its flagship products to solve through the cloud.

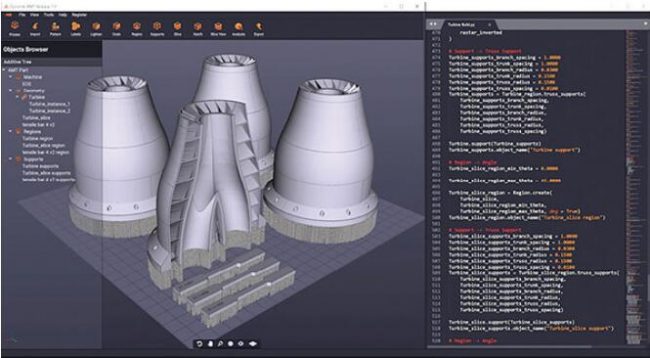

“We are also in the process of bringing all of the parts of our additive suite together in a single interface, and as we roll that out users will have the exact same option to solve to whatever hardware they want to solve on,” Stucker says. Dyndrite’s additive manufacturing software delivers semi-automated python scripting routines to enable the automation of repetitive and time-consuming tasks during the preparation of 3D data for 3D printing. Image courtesy of Dyndrite.

Dyndrite’s additive manufacturing software delivers semi-automated python scripting routines to enable the automation of repetitive and time-consuming tasks during the preparation of 3D data for 3D printing. Image courtesy of Dyndrite.

The Dyndrite solution serves as a bridge, similar to Adobe PostScript, that streamlines CAD-to-print workflows using a fast, GPU-powered geometry engine. In software demos, the product can create billions of voxels from a CAD file in just seconds, and slice the files just as quickly. “The only way to make that happen is using the GPU,” says Dyndrite CEO Goel.

“Existing geometry kernels were not built to handle these complex geometries,” Goel says. “Companies wasted a lot of money just loading files. Some customers we’ve spoken to used to take 60 hours to process a geometry. We help them cut that down to two. Some of this work can be completed on a laptop in less than 15 minutes. It dramatically affects iteration times and cycles.”

This type of tool also eliminates steps in the traditional process, which require CAD files to be translated to STL files, then sliced and sent to the printer software. “If something goes wrong in that process, you have to start all over again,” Goel says. “You aren’t just losing time, you are also losing quality because you constantly sacrifice quality in the importing and exporting process.”

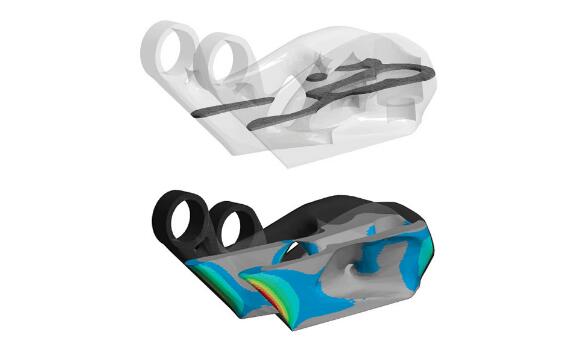

ANSYS provides a comprehensive and scalable software solution, which minimizes the risk of AM processes and ensures high quality, certifiable parts. Image courtesy of ANSYS.

ANSYS provides a comprehensive and scalable software solution, which minimizes the risk of AM processes and ensures high quality, certifiable parts. Image courtesy of ANSYS.

Dyndrite is also working closely with simulation providers like ANSYS and Altair to integrate its geometry creation capabilities with their software. “The creation of the voxels is an expensive operation that we can accelerate,” Goel says. “They still have to do the hard work on their side to [prompt] the GPU to simulate faster, but our goal is to provide the best geometry system so that part of the problem is taken care of.”

Goel sees STL eventually going away. “It’s a broken way of representing geometry,” Goel says. “This delivers on the promise of AM. We were promised unlimited complexity, but it’s not really unlimited because you still have a computer involved. If I want to hit the resolution of the machine, I need software and hardware to handle it.”

Better compute resources are also required to handle complex additive manufacturing data management.

“Cloud and HPC resources also play a role in data management when it comes to design optimization for AM. There is all this information about machines and materials, setting up default options in experiments, simulation results from before, best practices for simulation, etc.” Stucker says. “It isn’t just about how to design a component, but how do you keep track of this massive amount of information that has been generated through experiments and simulation?”

In ANSYS’ case the company’s Granta acquisition provides a simulation data management tool called Minerva that provides distributed access to that information.

![]() Navigating the Cloud

Navigating the Cloud

A variety of public, private and hybrid cloud infrastructures are available for companies that want to access design and simulation tools or tap into on-demand HPC resources. Increasingly, firms are more comfortable using public cloud services like Amazon Web Services (AWS), Microsoft Azure, IBM Cloud and others. Most software providers that offer cloud options also typically provide some flexibility for customers who either won’t or can’t (due to regulatory requirements) move to a fully public cloud infrastructure.

According to Stucker, early adopters in the cloud space have focused on private clouds, but that is slowly shifting to public cloud infrastructures. “These installed cloud architectures can become obsolete quickly,” Stucker says. “Leasing compute power makes more sense for companies than buying hardware and hiring a team to manage it.”

Goel, meanwhile, thinks that the next computing frontier in additive manufacturing will be pushing compute resources to the edge of the network, right down to the printers themselves. “The printers are increasing in size and in resolution, which means there is more data required to print,” Goel says. “Something needs to be in place at the point of manufacture to handle that data.”

As build volumes increase, the data required to create an object increases cubically. “This only gets worse as the machines grow in size,” Goel says. “The amount of horsepower needed for that data is increasing rapidly. The fact that the printers are getting bigger and more process creates a problem and a challenge. People are also making more complicated things. You need a better and more sophisticated geometry engine to handle those more complicated things.”

That could mean the possibility of real-time, in situ operational simulations that can help improve print quality and predictability. “If you are able to compute and simulate a part before it has been printed, the likelihood of a successful print goes up,” says Shawn Hopwood, Dyndrite chief marketing officer and head of OEM relations.

“We are seeing more people putting simulation and printing software inside the machines,” Goel says. “If you put a GPU in the machines, the printer is analyzing the part as it is being printed, re-simulating it and dynamically adjusting it. That’s only possible when the machine itself is fast enough to compute.”

These capabilities will grow in importance as more companies embrace additive manufacturing. “We’re seeing a transition away from managing additive as a niche area for a company, to applying additive throughout an entire product portfolio,” Stucker says. “To do that, we need everyone designing from the same data and the same assumptions. The only way to support enterprise-level sharing of resources is using the cloud and some form of HPC resources.”

Source: Digital Engineering

Recent Comments