How AI Builds A Better Manufacturing Process

Located 90 minutes west of Tokyo in the shadow of Mount Fuji, Oshino, Japan, is home to 9,000 people—which means that in any given year, the robots produced at the town’s FANUC plant out number humans by roughly seven to one. But as for how many humans it takes to construct those 5,000 banana-colored robots a month, don’t bother counting: The robots build themselves, test themselves and inspect themselves.

A generation ago, many people—including manufacturing executives themselves—would’ve considered such a facility as either science fiction or centuries away. To be certain, FANUC’s complex of 22 sub-factories is one of a kind. It’s one of the world’s first “lights-out factories”—where 24/7 operation is a reality and intelligent robots create computerized offspring capable, just like them, of machine learning and computer vision. But it proves just how far artificial intelligence (AI) has come in the manufacturing process.

In fact, artificial intelligence has brought us into a new dimension that extends beyond the walls of the FANUC plant. While robots have occupied the factory floor for some time, today’s robots no longer perform monotonous, mechanical tasks. They are smart participants in Industry 4.0: at its core, the linking of the real-life factory with virtual reality.

Why is AI so crucial for manufacturing? Part of it is the sheer scope of possible applications, from real-time maintenance of equipment to virtual design that allows for new, improved and customized products, to a smart supply chain and the creation of new business models.

There’s also no question that artificial intelligence holds the key to future growth and success in manufacturing. In a recent Forbes Insights survey on artificial intelligence, 44% of respondents from the automotive and manufacturing sectors classified AI as “highly important” to the manufacturing function in the next five years, while almost half—49%—said it was “absolutely critical to success.”

Today, humans and robots collaborate to produce breakthroughs, thanks to the “marriage” of advanced manufacturing techniques with information technology, and data and analytics. Here we look at key revolutions AI brings to the manufacturing industry.

![]() Computer vision

Computer vision

Even the most eagle-eyed human inspector would fail at finding flaws half the width of a human hair, for example. But a machine equipped with a camera many times more sensitive than the naked eye won’t miss a beat. The trick is to take what would seem like the next logical step—sending those images to a person to make judgments and corrections—and hand that over to the machine as well.

Landing.ai, a startup formed by Silicon Valley veteran Andrew Ng, has developed machine-vision tools to find microscopic defects in products such as circuit boards at resolutions well beyond human vision, using a machine-learning algorithm trained on remarkably small volumes of sample images. Once on line, the computer not only “sees,” but also processes the information and learns from what it sees. If it spots a problem or defect, it sends an immediate alert, an AI process known as “automated issue identification.”

![]() Generative design

Generative design

For manufacturers, artificial intelligence also comes into play through a new process called generative design. It works this way: Designers or engineers input design goals—along with parameters for materials, manufacturing methods and cost constraints—into generative design software. The software then explores all the possible permutations of a solution, and quickly “generates” design alternatives. Finally, it leverages machine learning to test and learn from each iteration what works and what doesn’t.

“If you’re trying to optimize a wing design for an aircraft, or a spoiler or battery design for the new electric car—or even just the plastic molds for your cell phone case—that has traditionally been a lot of work,” says Brian Mathews, vice president of platform engineering at Autodesk in San Rafael, California.

“With generative design, you can effectively rent 50,000 computers [in the cloud] for an hour,” says Mathews, who estimates the cost at about $20,000. “That means you can do things you never could have done before: You can do 50,000 days of engineering in one day.”

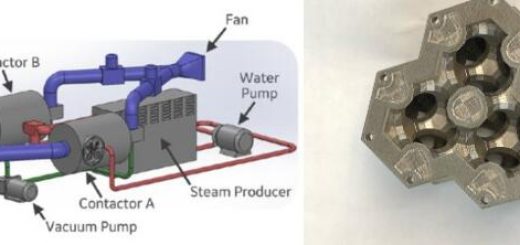

![]() Digital twins

Digital twins

A digital twin is a virtual model of a process, product or service. “This pairing of the virtual and physical worlds allows analysis of data and monitoring of systems to head off problems before they even occur, prevent downtime, develop new opportunities and even plan for the future by using simulations,” Bernard Marr, author of Big Data, writes in Forbes. The digital twin leverages the Internet of Things (IoT) but requires the skills of machine learning and artificial intelligence.

Digital twins are especially useful when working with equipment from a remote distance. Sensors embedded within a physical item gather data about real-time status, working condition or position. A cloud-based system receives and processes all the data that the sensors monitor. “Lessons are learned and opportunities are uncovered within the virtual environment that can be applied to the physical world—ultimately to transform your business,” Marr writes.

![]() Predictive maintenance

Predictive maintenance

Predictive maintenance—as opposed to preventive maintenance—eliminates guesswork as the machines report their conditions on an up-to-the-minute basis. It also saves businesses valuable time and resources, including labor costs, while guaranteeing optimal manufacturing performance. As with digital twins, sensors and advanced analytics embedded in manufacturing equipment make it possible. They enable predictive maintenance by responding to alerts and resolving machine issues.

An example of IoT usage and machine learning in predictive maintenance can be found in machines used for manufacturing titanium implants. A Deloitte report notes that titanium’s hardness requires tools with diamond tips to cut it. The dullness of those tips, “and thus the optimal time to sharpen them, has been difficult to figure out because of many different variables that affect it.”

Enter predictive maintenance: “The use of vibration or sound sensors and torque monitors can help assess the state of the machinery, as dull tips move and sound differently.” The best human operators can assess the state of the machinery by nuanced factors such as the amount of heat they feel on their faces coming from different parts of the machine or from how hard it was for the molded piece to be ejected from the mold itself. To bring all other operators up to the same level, inexperienced operators can be equipped with virtual reality-type glasses that see and sense all that the experienced operators do.

![]() Putting It All Together: AI As The Next Major factor In Manufacturing

Putting It All Together: AI As The Next Major factor In Manufacturing

On the one hand, missing the AI wave in manufacturing could mean getting stranded. And for some, that will be a reality. Forbes Insights research reveals that more than half of respondents (56%) in the automotive and manufacturing sectors plan to increase artificial intelligence spending by less than 10%.

“If you’re stuck to the old way and don’t have the capacity to digitalize manufacturing processes, your costs are probably going to rise, your products are going to be late to market, and your ability to provide distinctive value-add to customers will decline,” says Stephen Ezell, an expert in global innovation policy at the Information Technology and Innovation Foundation.

Yet it’s not too late to adapt the manufacturing process, and the sector at large, to the changes already taking place. We’re clearly in the early stages of the sea change, and as a recent ITIF report concludes, “There remains a long way to go before this vision is fully realized.”

Source: itac

Recent Comments