BLT Installs 200th Metal 3D Printer for Its Internal AM Service

On November 8, BLT (Bright Laser Technology) held the delivery ceremony for the 200th metal 3D printer delivered to BLT’s AM production department (its internal AM service) together with the celebration for the overall delivery of 80-tons of powder in 2021. The ceremony was held in BLT’s E plant. Xue Lei, Chairman and General Manager of BLT, Zhao Xiaoming, Deputy General Manager, and Yang Donghui, Deputy General Manager, attended the ceremony along with management and representatives of the production department, new materials department and equipment line.

3dpbm’s latest report on Metal AM (and the subsequent AM Services eBook) was the first to ever highlight BLT’s dominant position among metal AM services, as well as hardware manufacturing. This announcement further validates and confirms 3dpbm’s early insights.

At the delivery ceremony, Xue Lei, Chairman and General Manager of BLT, reviewed the development history and mission of the company’s equipment line and new material business line, and affirmed the contributions of the three major business lines to the company’s development. He cut in from the perspective of industry development, emphasized the strategic tasks of the three major business lines, and urged everyone to “fix the green hills and not relax”, go forward together, and work hard.

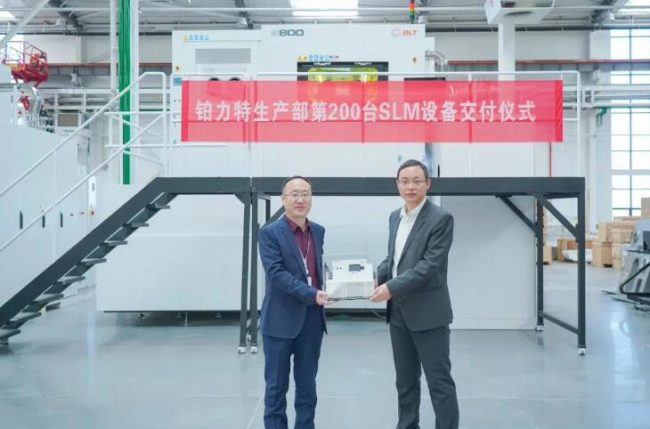

The equipment manufacturing department and the production department signed the delivery documents on site and exchanged the BLT-S800 equipment model. The BLT-S800, the 200th metal 3D printer delivered by the equipment manufacturing department to the production department, is the company’s star product, recently released at TCT Asia. The BLT-S800 is a ten-laser device independently developed by BLT. It is mainly used in aviation, aerospace, engine, medical, automobile, electronics, mold, scientific research institutes and other fields.

Blite Deputy General Manager Zhao Xiaoming and Deputy General Manager Yang Donghui attended the delivery ceremony

Blite Deputy General Manager Zhao Xiaoming and Deputy General Manager Yang Donghui attended the delivery ceremony

The New Materials Department also delivered 2,100 Kg of titanium alloy powder to the Production Department. Up to now, the New Materials Department has delivered a total of 80 tons of high-quality powder to the Production Department in 2021, used for carrying out 3D printing service orders.

The venue for this delivery ceremony was the large-size equipment printing service workshop, built in the second phase of BLT expansion. It covers an area of 78 acres and consists of a research and development center and three metal additive manufacturing plants, all of which will be put into use in 2021.

The large-size equipment printing service workshop is equipped with large-size metal 3D printing equipment for 3D printing services. It plans to configure more than 90 large-size equipment, mainly providing large-size parts for users in aviation, aerospace, engines, automobiles and other fields.

New materials department delivered titanium alloy powder to production department

New materials department delivered titanium alloy powder to production department

2021 is the tenth year since BLT’s establishment. Now the company’s business covers raw materials, equipment, printing services, technical consulting and software, etc., established a relatively complete metal additive manufacturing industry chain, and established the field of metal 3D printing. This setup offers the most complete localized AM technology development system anywhere in the world.

In the future, Bright will continue to focus on the main channel of metal 3D printing, refined technology, research and application, and expand the market, adhering to the mission of “making manufacturing simpler and the world better”, leading the large-scale production era of metal additive manufacturing.

Source: BLT

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments