Kennametal Offers Its Most Corrosion Resistant Tungsten Carbide Grade for AM

Kennametal Inc., Pittsburgh, Pennsylvania, USA, has launched KAR85-AM-K, its most corrosion resistant tungsten carbide grade for metal Additive Manufacturing. KAR85-AM-K is reported to combine the wear performance of conventional tungsten carbide with the design flexibility of AM to produce high-performance parts for oil and gas, power generation and other demanding applications.

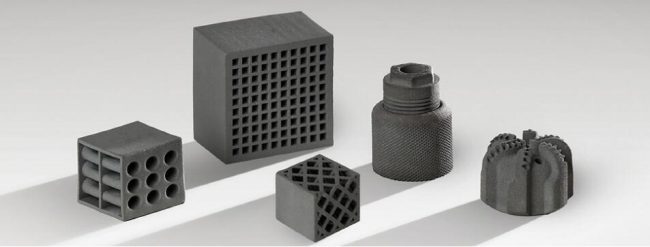

Kennametal offers a range of powders for Additive Manufacturing, including the new KAR85-AM-K grade (Courtesy Kennametal)

Kennametal offers a range of powders for Additive Manufacturing, including the new KAR85-AM-K grade (Courtesy Kennametal)

Combined with Kennametal’s Binder Jetting (BJT) Additive Manufacturing capabilities, KAR85-AM-K is said to provide corrosion and wear resistant properties comparable to conventional CN13S grade. Components made with the new material are already in field trials with select customers.

“Kennametal is leading the way in tungsten carbide Additive Manufacturing by combining the superior wear and corrosion resistance of our new KAR85-AM-K grade with deep expertise in binder jet 3D printing,” said Jay Verellen, General Manager, Kennametal Additive Manufacturing. “With this new grade, we’re delivering the best of both worlds for our customers—the highly desirable material properties of conventional tungsten carbide with the design flexibility of additive—for high performance components that go the distance in the most demanding applications.”

The new grade composition features a proprietary blend of cobalt, nickel, and chromium for improved corrosion resistance compared to standard cobalt-based tungsten grades. It is Kennametal’s second commercial carbide grade developed for use in its BJT processes and the latest addition to the business’s portfolio of high-performance metal powders optimised for AM.

Kennametal Additive Manufacturing, the company’s AM business unit within its Infrastructure segment, offers comprehensive solutions, from raw material to finished part. The business develops carbide, cobalt, nickel and iron powders, including Stellite™ alloys, optimised for specific Additive Manufacturing processes. At Kennametal’s research and development, prototyping and production centre in Latrobe, Pennsylvania, the business utilises Laser Beam Powder Bed Fusion (PBF-LB) and BJT technologies, combined with post processing capabilities, to produce fully finished components for customers.

Source: Kennametal

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments