Optomec Adds Aluminum to Dozens of Metal Additive Printing Recipes

August 10, Optomec Inc., a leader in production solutions for Metal Additive Manufacturing and 3D Printed Electronics, announced it has added 7000 series Aluminum to its growing list of qualified alloys for use in its LENS 3D DED metal printers. Manufacturers in many industrial and aerospace segments demand 7000 series aluminum for 3D Metal Additive Manufacturing, as it possesses the highest strength of all the aluminum series alloys and is commonly used in high-stress parts such as aircraft landing gear components. This new alloy capability is enabled by Optomec’s latest laser optics solution–now standard in all of its LENS 3D metal printers–that allows the size and profile of the laser-heated region to be remotely adjusted for a particular alloy. This is a first in the industry.

7000 Series Aluminum is commonly required for aviation parts such as landing gear components

7000 Series Aluminum is commonly required for aviation parts such as landing gear components

Developing qualified process parameters relies on expertise and resources that Optomec uniquely possesses. Optomec has 20 years as the market leader in delivering LENS-DED printer solutions during which it has generated 100s of man-years of internal process knowledge related to real-world applications. Further, with more than 200 LENS-DED machines installed across leading manufacturers, governments, and universities, Optomec benefits from 1,000s of man-years of user experience to draw from.

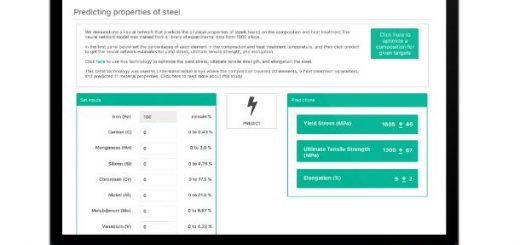

Different metals and alloys require different sets of process parameters, referred to as “process recipes.” Depending on the alloy, it can take months of experimentation to optimize a recipe for a new alloy, including powder screening, process development and tuning, samples production, mechanical testing, metallurgical analysis, etc. To save its customers time and development cost, Optomec offers qualified Process Recipes for a wide range of common alloys including basic steels; titanium; inconel and other superalloys; corrosion-resistant alloys; wear coatings; thermal barrier coatings; thermal-conduction alloys such as copper; and now Aluminum alloys, including 7000 series. Recipes are available for a range of print scenarios, including thin-walled, high-resolution and bulk deposit versions as “starter recipes,” or it can develop part-specific production recipes for specific end-user geometries upon request. Further, Optomec is developing “Print Libraries” that include print geometry for specific common LENS applications, such as turbine blade repair.

“We can develop new material recipes much faster now.” said Lucas Brewer, head of Optomec’s Applications Engineering Group in Albuquerque, “Our new deposition head technology is really the key to getting the DED process to print these new alloys in a repeatable way for our production customers. It’s opened up a ton of new applications for Metal Additive Manufacturing.”

Optomec is a privately-held, rapidly growing supplier of Additive Manufacturing systems. Optomec’s patented Aerosol Jet Systems for printed electronics, and LENS and Huffman brand 3D Printers for metal component production and repair, are used by industry to reduce product cost and improve performance. Together, these unique printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. Optomec has delivered more than 500 of its proprietary Additive Manufacturing systems to more than 200 marquee customers around the world, for production applications in the electronics, energy, life sciences and aerospace industries. Our users include countless blue-chip manufacturing companies, such as GE, Samsung, Raytheon, Siemens, Lockheed and LiteOn, as well as the US Air Force, US Navy, US Army and NASA.

Source: Optomec

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments