SEURAT INSIGHTS, A New Era in Metal Part Production

![]() Tool-bound production limits innovation

Tool-bound production limits innovation

For centuries, tool-bound technologies such as casting, forging and sheet metal forming dominated the way we produce metal components. Across all industries from automotive to aerospace, medical, and consumer goods, designers and engineers are relying on materials, design capabilities and production costs these technologies are offering.

Tool-bound manufacturing in combination with machining operations offers a reliable process chain to bring metal feedstocks into the desired form. Therefore, companies have accepted the resulting months-long lead time until start of production and adapted to the limitations of tool-bound manufacturing by rigid production planning schedules, which limit design changes months before start of production.

Today’s engineers, however, are facing new challenges regarding shorter product lifecycles and increased requirements on carbon footprint and material performance. At the same time, digitalization and on- demand manufacturing are changing global supply chains and demand for more flexible manufacturing technologies. Although tool-bound technologies have been continuously improved over the past 100 years, their basic principle remains the same and the enormous initial bound capital and limited flexibility of tools hinders further innovations in metal manufacturing. More than ever, engineers are searching for technologies that allow fast product development at minimized material usage and energy input.

Casting of metal components—the old way.

Casting of metal components—the old way.

![]() Today’s 3D printing technologies show very limited commercial impact

Today’s 3D printing technologies show very limited commercial impact

3D Printing (or Additive Manufacturing) technologies promised to offer what engineers were looking for: a digital process chain with high freedom of design, tool- less manufacturing with lead times of days instead of months, small carbon footprint, reduced waste and the potential for optimized lightweight structures. Possibilities appeared endless and provided engineers with a seemingly inexhaustible toolbox, waiting to be discovered. Additive Manufacturing seemed to be the holy grail of modern manufacturing and allowed for completely new part designs.

For the past 30 years, designers and engineers have spent thousands of man-hours exploring the potential of 3D printing technologies and presented endless use cases to their stakeholders and customers. However, so far, only 10.000 metal 3D printing systems have been installed worldwide. Many are located at R&D labs, and only a fraction have made it to the production shop floor.

Viable applications are limited to high end parts such as medical implants and turbine components. Despite enormous advancements in topology optimization, bionic lightweight design and optimized engineering cycles, there is one key aspect missing which results in many ideas never making it into production: in the end, the cost of today’s Additive Manufacturing is just too high.

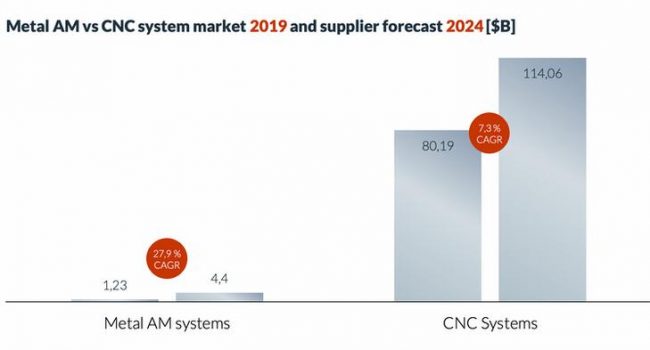

The lack of penetration in industrial applications can be seen when comparing market numbers of AM systems with conventional metal processing technologies. Although the growth rate of AM systems is projected to be higher, the overall installed base and system revenue is miniscule in comparison to CNC machining. Source: AMPOWER 2020

Source: AMPOWER 2020

![]() The economics behind today’s metal 3D printing technology

The economics behind today’s metal 3D printing technology

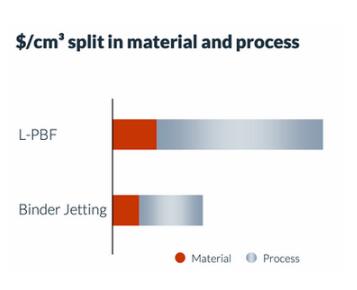

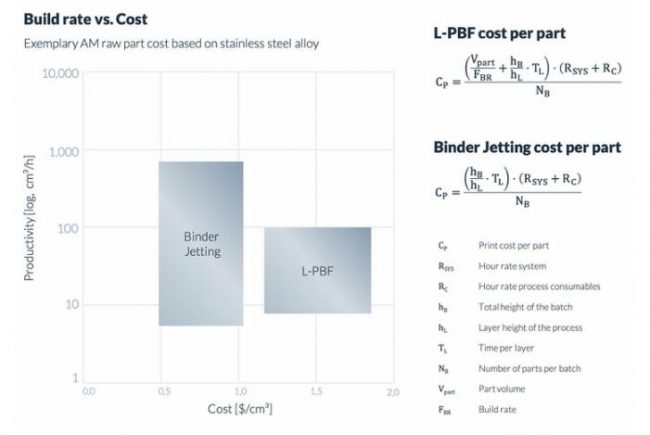

The drivers of today’s AM part cost are build rate, machine investment and feedstock price. Of those three, the build rate has the highest impact, especially for Laser Powder Bed Fusion (L-PBF), the most common AM technology. Increasing this parameter leads to significantly lower cost. Today’s L-PBF systems achieve build rates between 10-100 cm3/h, while Binder Jetting promises to reach up to 900 cm3/h for green part printing. Depending on alloy and part geometry, achievable volume cost range between 0.5 – 1.8 $/cm3.

Source: AMPOWER 2021

Source: AMPOWER 2021

![]() Revolutionary approach opens new opportunities

Revolutionary approach opens new opportunities

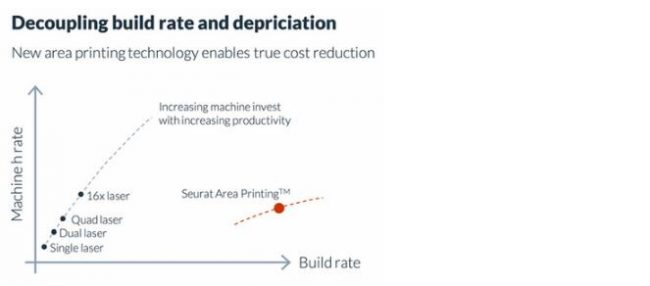

Only reduced part costs lead to higher adoption rates and new opportunities for metal Additive Manufacturing. To decrease cost, today’s metal AM suppliers follow an approach of using multiple laser sources. Additional laser sources allow for simultaneous melting of material and consequently increased build rates. However, additional laser sources and corresponding optical system components are inherently expensive which increases machine costs and reduces the positive effect on cost per part. Thus, an increase in build speed is coupled with an increase in investment and system depreciation cost.

Build rates of more than 1000x of today‘s systems are possible with Seurat’s Area Printing technology

Seurat Technologies has invented a novel area printing approach which has the potential to break through the limits of today’s metal Additive Manufacturing. Rather than increasing the number of laser sources, this new technology uses a completely new method of beam manipulation to increase melted volume per time. While the usual metal AM system works with a spot diameter of 100 μm, the Seurat system delivers two million points of laser light into a 15 mm square area, with each point of light having a roughly 10 μm diameter. With this method, Seurat can simultaneously increase build rate massively, while also improving resolution. Seurat TechnologiesTM increases the build rate up to 1000x compared to other single laser system.

Seurat Technologies patented Area Printing process

Seurat Technologies patented Area Printing process

![]() The Impact of Area Printing: Decoupling speed and resolution

The Impact of Area Printing: Decoupling speed and resolution

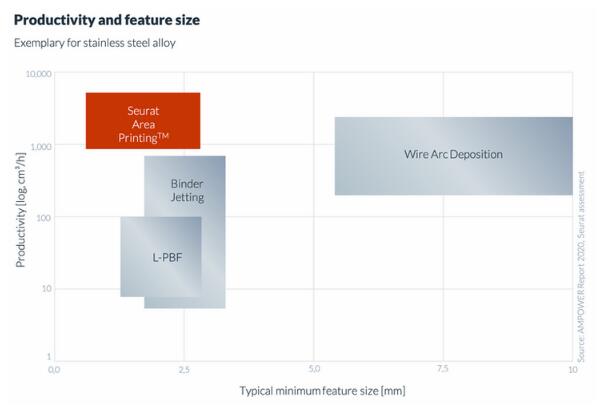

An increase in productivity is the main goal of almost every new 3D Printing technology introduced into the market. Two of the most prominent examples in metal Additive Manufacturing are Wire Arc Deposition and Binder Jetting. Wire Arc Deposition uses a wire-based welding process to deposit the material. The high deposition rate, however, has limits in terms of resolution resulting in typical minimum feature sizes in the range of 5-10 mm. Binder Jetting is based on ink jet printing technologies printing green parts with high productivity, however the fragility of green parts leads to limited feature sizes if a high productivity is targeted. The two-step process also makes the technology difficult to master since deformation and sintering know-how is required. Currently, build rates between 400-1,500 cm3/h are possible with these two technology approaches.

Seurat’s Area Printing technology enhances the widely known L-PBF approach by increasing the productivity way above the limits of any existing metal 3D Printing technology. While it utilizes build rates even higher than that of Wire Arc Deposition, it maintains the accuracy and resolution of Laser Powder Bed Fusion and has the potential to further improve surface quality and part flexibility.

Source: AMPOWER Report 2020, Seurat assessment

Source: AMPOWER Report 2020, Seurat assessment

![]() What if additive can beat conventional?

What if additive can beat conventional?

Additive Manufacturing has been struggling to prove commercial feasibility since its beginning. High feedstock cost, slow process speed and high capital investments made it difficult for engineers to make a positive business case when using AM. On the other hand, cost structures of traditional technologies such as casting, forging or machining have been optimized over the past 100 years. Nevertheless, a few serial AM applications are making it to the end users. Business cases are based on reduced lead time, optimized weight, reduced assembly cost or increased performance.

Seurat’s area printing technology breaks through the existing barrier of cost per part. The first system generation will already offer a cost reduction of 50% compared to today’s Additive Manufacturing technologies. The unique technology principle, however, has the potential to decrease cost much further. Future machine generations will target manufacturing costs beating conventional die casting processes by the year of 2030. This will mark the breakthrough of Additive Manufacturing as a mainstream technology.

Seurat’s Area Printing technology breaks through the existing barrier of cost per part.

Seurat’s Area Printing technology breaks through the existing barrier of cost per part.

Even for very low-cost automotive parts, Area Printing can achieve price points that out-compete on pure cost alone.

Even for very low-cost automotive parts, Area Printing can achieve price points that out-compete on pure cost alone.

![]() Unlocking new markets

Unlocking new markets

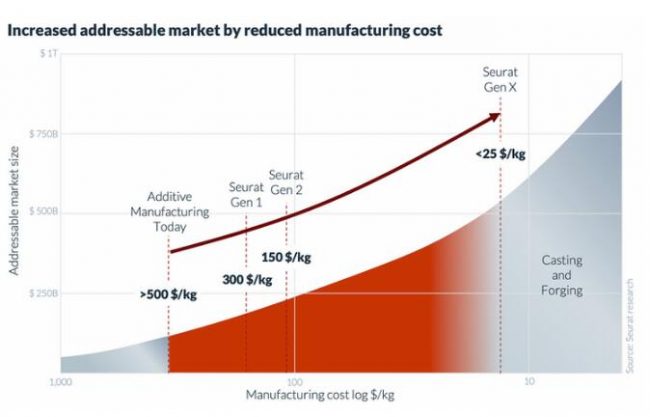

The global metals manufacturing market reached a volume of about $1T in the past decade. High volume forging and casting applications cover a large portion of the market due to their low cost, high availability and established processes. With decreasing manufacturing cost per part, the market shares grow significantly.

Additive Manufacturing today covers a small fraction of the market, mostly focusing on high value applications in medical and aerospace. Parts with high performance requirements that are usually already expensive in traditional manufacturing technologies offer the ideal business case for conventional Additive Manufacturing technologies.

Seurat targets to penetrate significantly larger markets by further deceasing the manufacturing cost. With the first generation of machines, manufacturing cost of around 300 $/kg are achievable which potentially doubles the addressable market size. The real game changer can be expected with the second-generation system expected in 2024, and further with later systems in 2027 and 2030. GenX will decrease manufacturing cost to below 25 $/kg unlocking significantly larger markets in metal manufacturing.

Source: Seurat research

Source: Seurat research

![]() Siemens Energy: Gas turbine main swirler

Siemens Energy: Gas turbine main swirler

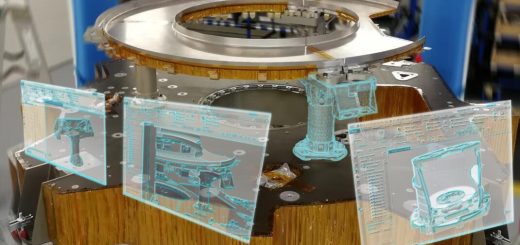

Siemens Energy is one of the leading global Additive Manufacturing pioneers. Be it rapid prototyping or manufacturing parts for aero-derivative, gas and steam turbines or compressors, they can be designed faster, with increased flexibility, better materials, and optimized efficiency.

One major application that already made it into production are gas turbine swirlers. Those components are mounted in an advanced combustion system of a Siemens SGT 5/6 8000H gas turbine for mixing of fuel gas with compressed air. Additive manufacturing leads to a reduction from 8 parts to one, improved lead time and positive business case achieved by optimized design and industrialized manufacturing process.

![]() Porsche: Electric drive housing

Porsche: Electric drive housing

The additively manufactured aluminum housing is lighter than a conventionally cast part and reduces the overall weight of the drive train by approximately ten percent. Using special structures that have only become possible due to 3D printing, the stiffness in highly stressed areas has nevertheless been doubled.

Additional potentials arise in the areas of process innovation – agile development and flexible production – and for new areas of business such as customization with new offers for customers and spare parts. This manufacturing technology is technically and economically interesting for Porsche specifically for special and small series as well as motorsports.

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments