India Developed New Multi-Functional Heat Sink Enabled By 3D Printing

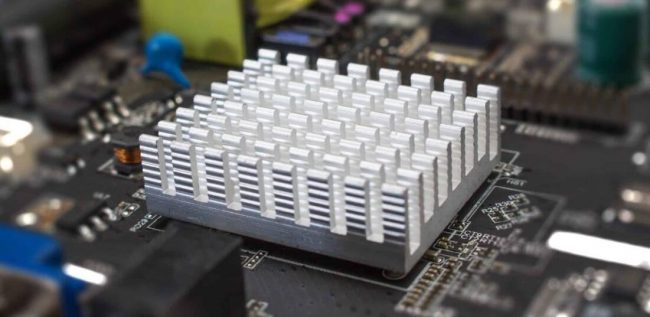

Prof. Shankar Krishnan & Prof. Sripriya Ramamoorthy, Associate Professors at the Department of Mechanical Engineering, IIT Bombay have developed a multifunctional heat sink enabled by 3D printing, which can dissipate heat from mechanical devices at 50 percent enhanced rate compared to conventional sinks.

Existing approaches for heat exchanging and heat sink achieve different functions using dedicated units.

Prof. Shankar Krishnan & Prof. Sripriya Ramamoorthy Developed Heat Sink.Prof. Shankar Krishnan & Prof. Sripriya Ramamoorthy Developed Heat Sink.

In the new technology, multiple functions have been integrated together in a single unit. It can also be used to develop heat pipes, vapour chambers, heat exchangers and noise reducing heat sinks.

The technology enabled by 3D printing in combination with electroplating was developed to withstand load while dissipating heat by Dr Shankar Krishnan and Dr. Sripriya Ramamoorthy, Associate Professors at the Department of Mechanical Engineering, IIT Bombay with support from IMPRINT and the Advanced Manufacturing Technologies Programme of the Department of Science & Technology, Government of India aligned with the ‘Make in India’ initiative. They have also filed a national patent on ‘noise reducing heat sinks’ and international patent will be applied subsequently. Experimental as well as computational validation has been carried out.

Electroplated SampleElectroplated Sample

The technology is lightweight and can bear mechanical compressional loads, dissipate heat and absorb sound/noise. It can be used in the electronics cooling, electronics as well as power/cooling industry.

Based on open-literature survey, no such product exists in the market presently. Thermal management of electronics is a ten-billion-dollar market and is a potential beneficiary of this technology. Additionally, any fan-mounted heat exchanger can benefit from this development. Cost is a risk factor but partnering with high volume manufacturers will reduce this risk.

The technology is in third stage of Technology readiness levels (verification with experimental to verify that the concept works as expected) and Prof. Krishnan is in discussions with major semiconductor manufacturer for high volume manufacturing and will work further to enable compact noise (both broadband as well as tonal) reducing heat sinks.

Source: Chronicle

Recent Comments