E-Plus: Four Lightweight Designs of Metal 3D Printing Technology

Macroscopically, lightweight materials such as titanium alloy, aluminum alloy and magnesium alloy can be used to achieve this goal. At the micro level, materials such as high-strength structural steel can be used to make the parts more compact and smaller, thus helping to reduce weight.

3D printing brings the feasibility of realizing lightweight through structural design. Specifically, there are four main ways for 3d printing to achieve lightweight through structural design: hollow interlayer/thin-wall stiffened structure, hollow lattice structure, integrated structure, and special-shaped topology optimization structure.

![]() ApproachⅠ. Hollow interlayer/thin-wall stiffened structure design

ApproachⅠ. Hollow interlayer/thin-wall stiffened structure design

Hollow interlayer/ thin-walled stiffened structure is usually composed of a thinner panel and a thicker core. Under the bending load, the surface material mainly bears the tensile stress and compressive stress, while the core material mainly bears the shear stress and partial compressive stress. Interlayer structure has the advantages of light weight, high bending stiffness and strength, strong anti-instability ability, fatigue resistance, sound absorption and heat insulation.

In aviation, wind turbine blades, ships, trains and other fields, lightweight interlayer structures are widely used to reduce weight.

The interlayer structure realizes the rapid weight reduction of components. The interlayer structure has good dispersion effect on the external pressure, and the thin-walled structure (such as wall thickness less than 1 mm) is conducive to weight reduction. Interlayer and other similar structures can be used as radiators, which greatly improve the heat exchange area and heat dissipation efficiency of parts

![]() ApproachⅡ. Hollow lattice structure

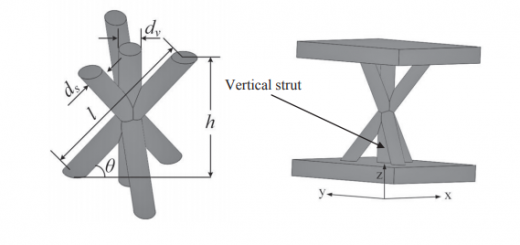

ApproachⅡ. Hollow lattice structure

The hollow lattice structure can achieve the perfect balance of engineering strength, toughness, durability, statics, dynamics and manufacturing cost. The relative density of crystal lattice, the shape, size, material and loading rate of cells are adjusted by periodically duplicating a large number of single cells for design and manufacture, so as to adjust the mechanical properties of the structure, such as strength and toughness.

The 3d lattice structure has a high degree of spatial symmetry, which can evenly disperse the external load, reduce the weight and ensure the bearing capacity. In addition to the engineering requirements, the hollow lattice structure also has a gap (adjustable aperture), which facilitates the integration of the human body and the implant tissue in the application of the implant.

The design of lattice element is very flexible, and lattice elements with different shapes, sizes and porosity can be designed according to the use environment. In the area with high structural strength, the density of lattice element can be adjusted to be larger and the hollow lattice element with high structural strength can be selected. In the area with high requirements for weight reduction of component, hollow lattice structure with large weight reduction range can be added. The hollow structure can be arranged regularly or randomly to form irregular pores. In addition, the hollow structure can also present gradient transition arrangement of variable density and thickness to meet the requirements of the overall gradient strength of the components.

![]() Approach Ⅲ. Integrated structure

Approach Ⅲ. Integrated structure

3d printing can integrate parts originally composed of multiple parts into printing, which not only realizes the integral structure of parts, but also avoids the connection structure (flanges, welds, etc.) existing in the original combination of multiple parts, and helps designers to break through constraints and realize functional optimization design.

The integrated structure through 3d printing not only improves the tendency of nozzle overheating and carbon deposition, but also increases the service life of the nozzle and improves the performance of the engine.

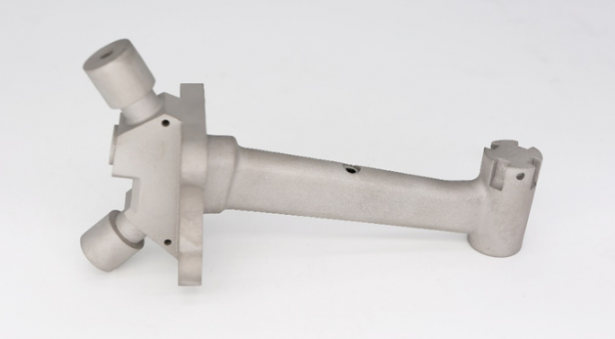

![]() Approach Ⅳ. Special-shaped topology optimization structure

Approach Ⅳ. Special-shaped topology optimization structure

Topology optimization is an important method to shorten the process of additive manufacturing design. It is used to identify and remove the materials that do not affect the rigidity of the part. Topological methods determine the optimal material distribution within a certain design range, including boundary conditions, pretension, and load capacity etc.

Topology optimization redistributes materials from the original parts, which can usually achieve functional optimization according to weight reduction requirements. After topology optimization, the special-shaped structure is simulated and analyzed to complete the final modeling, these designs cannot be processed by traditional machining methods, but can be realized by 3d printing. Usually, 3d printed products and parts manufactured by traditional processes need to be assembled together, so the connection structure design of the two parts should also be considered in design.

The above-mentioned four 3d printing structures are one of the directions to realize mechanical lightweight, and it is a systematic project. From the design optimization and manufacturing of each key component to the research and development and application of lightweight materials, it is indispensable on the road of lightweight exploration.

Source: E-Plus-3D

Recent Comments