Materialise, HP to design customised 3D-printed insoles

Materialise, through a partnership with RSPrint, has joined hands with HP to scale an end-to-end 3D solution to design and manufacture fully customised 3D-printed insoles. The two have entered into an agreement under which, FitStation powered by HP will integrate Materialise software for 3D design automation, print preparation and production management.

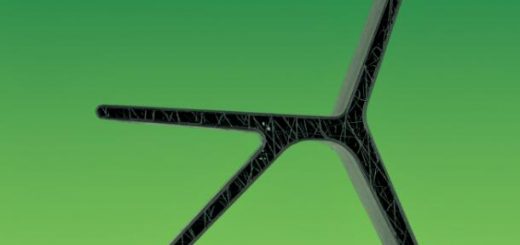

Image credit:Materialise

This alliance offers footwear brands the opportunity to express their unique brand proposition by allowing them to produce truly individualised products on-demand.

FitStation powered by HP is a platform that delivers custom-fitted and individualised footwear through innovative 3D scanning, dynamic gait analysis and manufacturing technologies. It provides individual off-the-shelf shoe and insole recommendations, 3D-printed insoles and individualised custom footwear. The Materialise software suite will now be integrated into FitStation, enabling brands to design innovative and customised insoles. The Materialise software suite manages and automates the print preparation and production process of the insoles, allowing manufacturers to scale their 3D printing business with efficiency and reliability.

“3D printing holds the promise of revolutionising the footwear industry by offering a level of customisation never seen before”, says Fried Vancraen, Materialise CEO. This makes it possible and cost-effective to mass manufacture entirely individualised products. As a complementary manufacturing technology 3D Printing allows for fundamental design optimisations and functional improvements, such as lighter designs, that are impossible to create with standard manufacturing technologies.

3D printing also empowers companies to transition towards an end-to-end digital manufacturing process, allowing for decentralised, on-demand manufacturing. As a result, retailers will be able to sell products they don’t have to keep in inventory. In addition to minimising stock-related costs and risks, retailers can also anticipate fewer product returns by providing customers with a precise fit and individualised design.

Materialise, with over 27 years of experience in 3D printing, helps footwear brands to unlock the full potential of the technology by offering support and automation during every step of the Additive Manufacturing process, from design to printed part. Materialise is a pioneer in creating personalised 3D printed insoles. With the introduction of Phits in 2014, Materialise, together with gait-analysis experts RS Scan, became the first company to create 3D-printed insoles based on dynamic measurement footscans.

Recent Comments