Use of Reverse Engineering to 3D Print Unique Car Hook Cover

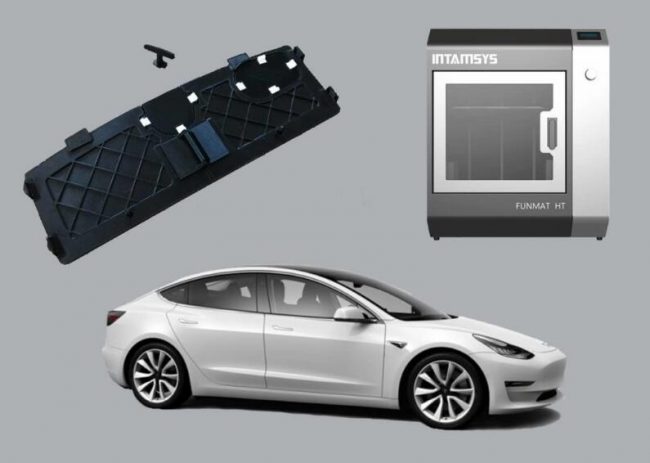

Thanks to Reverse Engineering, 3Way (3D technology solutions provider) created a unique hook cover for a customer’s car.

The Reverse Engineering process here involved, 3Way’s expertize as well as the use of 3D Scanning technologies (Shining3D EinScan HX), CAD modeling Software (ThinkDesign), and INTAMSYS’ 3D Printer, the FUNMAT HT.

Discover below the whole process on how to reverse-engineer a car hook cover and 3D print it.

![]() It all started with a problem and an idea

It all started with a problem and an idea

Nowadays, the problem is no longer so difficult to solve, you only need to find a service that provides it. The customer came to 3Way with a problem that was very interesting for them as well. The hook cover on the car fell off while driving or was stolen, and the customer needed a new one.

The 3Way team got an idea of how to fill a hole in the chassis, using the full spectrum of 3D technology. Of course, something like this requires enough knowledge and experience. Initially, part of the chassis had to be scanned with a 3D scanner and the data obtained processed. This was followed by 3D modeling and finally 3D printing of the hook cover.

![]() Step 1 – 3D Scanning

Step 1 – 3D Scanning

The hook gap that needed to be closed was located at the bottom of the car. Access was a bit more difficult as part of the chassis had to be scanned. The scanner choice was to use the EinScan HX 3D scanner, which is convenient and accurate for capturing surfaces. It was not necessary to apply spray or markers prior scanning on the surface. Despite the difficult accessibility, the team managed a very good scan.

3D scanning was followed by processing the data of the scanned part in the software of the scanner. With some editing, they got a good enough model that represented a solid basis for further work.

![]() Step 2 – Finalizing the CAD file of the hook cover using a 3D modeling Software

Step 2 – Finalizing the CAD file of the hook cover using a 3D modeling Software

3Way’s experts used ThinkDesign program to model the hook cover. The software includes useful features and is an excellent platform for drawing a model of any shape. Quite a few factors had to be taken into accounts, such as resistance to vibrations when driving and the outside temperature. Electric cars do not overheat to the same extent as others, but in the summer months, the reflection of the sun’s rays can quickly lead to too high values.

As it can be seen in the pictures, the hook cover is not made of a single piece, but consists of several smaller ones. The central part consists of two larger surfaces that close the opening and are connected by a folding element for easier installation. The plates have an additional element of ribs, which allows sufficient rigidity and prevents bending. They are made of ABS plastic.

The side pins are made separately, as if any breaks it is not necessary to replace the entire plates, but simply replace just them. They are made of ASA plastic.

Two more screws had to be made for fastening. They were screwed into the chassis, which stabilized the cover in place.

![]() Step 3 – Bringing the file to life by 3D Printing it

Step 3 – Bringing the file to life by 3D Printing it

To print the pieces, the 3D technologies specialize company decided to use INTAMSYS FUNMAT HT 3D printer, as it offers industrial-grade quality of printed pieces. The advantage is the thoroughly insulated and heated chamber (up to 90°C). With slow cooling, it allows the final piece not to curl. They were satisfied with the final product.

![]() Installation of the hook cover on the car

Installation of the hook cover on the car

Mounting the cover was quick and easy. The gap has closed completely, leaving all the dirt outside the car’s chassis. They also tested the removal of both intermediate plates with a screw to make sure the customer could use the cover functionally. Everything went according to plan and they believe that the customer will be satisfied with the solution and the useful value of the hook cover for a long time in the future.

Source: INTAMSYS

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments