MSU Receives $2.3 Million Grant to Advance Scalable, Compact and Low Cost Heat Exchanger

The U.S. Department of Energy’s Advanced Research Projects Agency-Energy, or ARPA-E, awarded Michigan State University a $2.3 million grant to deepen its growing expertise in additive manufacturing, known as 3D metal printing, and high-efficiency power generation.

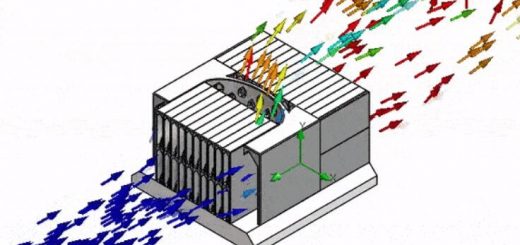

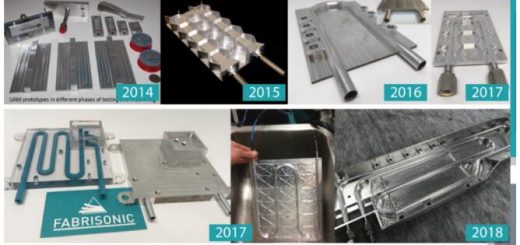

Andre Benard, associate professor of mechanical engineering, will serve as lead investigator on the funded project. The technology features a plate-type heat exchanger manufactured using new, high-temperature alloys suitable for powder-based manufacturing.

The goal, Benard said, is to develop a highly scalable, compact and low-cost metallic heat exchanger that is resistant to corrosion and can remain strong at the highest operating temperatures.

“The heat exchangers we’re working on are needed in systems like concentrated solar towers, nuclear power systems and for recapturing energy from industrial gas furnaces,” Benard said. “There is a demand for compact heat exchangers that can operate at temperatures close to 2,000 degrees Fahrenheit – and the existing ones are large, costly and do not meet the temperature requirement.”

Grid-scale power plants can be much more efficient when using supercritical carbon dioxide – which is a state of matter where liquid and gas phases are indistinguishable – as a working fluid instead of water.

“The new and efficient CO2 plants envisioned by many scientists require highly efficient heat exchangers. We are pushing the boundaries with these new metallic systems that can operate at high pressure and extreme high temperature,” Benard said. “These breakthrough power plants will require less thermal energy to produce electrical energy, be more compact, and will lower costs for customers and electric utility companies.”

The hope, Benard said, is that the new heat exchangers will handle the required power and durability of a power plant’s lifetime.

Source: MSU

Recent Comments