Better Heat Exchangers with Additive Manufacturing

Heat exchangers are the poster child of metal additive manufacturing. It’s true. Every time a metal 3D printer manufacturer wants to demonstrate the attributes of metal additive manufacturing, they create a compact, light-weight heat exchanger with complex internal channels. Why?

Let’s take a look at how these components needed improving and how redesigning them for additive manufacturing made them exponentially more efficient and more affordable, yet some hurdles remain in their adoption.

![]() What is a Heat Exchanger?

What is a Heat Exchanger?

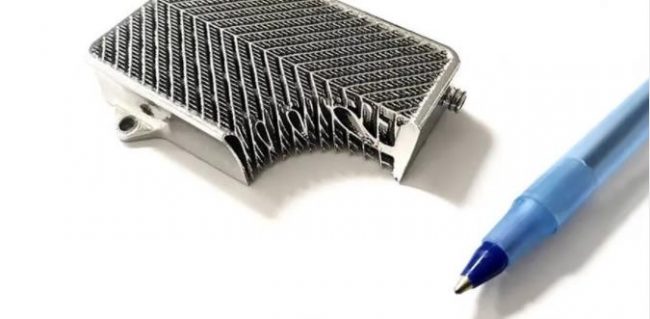

3D printed heat exchanger by 3D Systems (Source: 3D Systems)

3D printed heat exchanger by 3D Systems (Source: 3D Systems)

In simplest terms, a heat exchanger is a device that is used to transfer heat between two different fluids. You can find them in everything from air conditioners to rocket engines since they have a very broad range of applications.

Their cooling function is used to prevent equipment from overheating, while they also enable heat from one fluid to pass to another fluid with the primary purpose of heating it. The design is often a complex balance between maximizing the surface area of the part but minimizing the pressure drop within the part.

Today, advances in design for additive manufacturing are leading to breakthroughs in reimagining this most elementary part. Recently, a heat exchanger prototype from GE was able to handle temperatures of 900ºC, which is 200°C above current state-of-the-art devices. GE Research says that its prototype could find applications within the energy sector to enable “cleaner, more efficient power generation in both existing and next-generation power plants and jet engine platforms.”

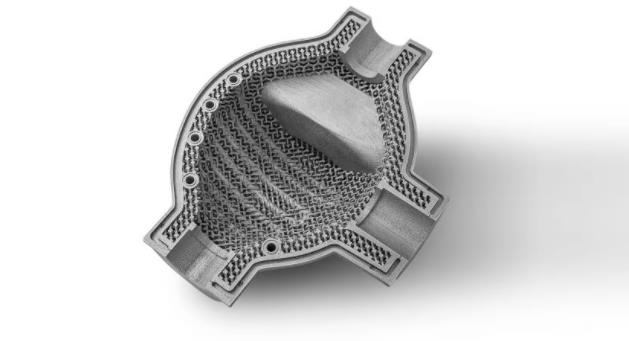

Monolithic heat exchanger 3D printed by Stratasys (Source: Stratasys)

Monolithic heat exchanger 3D printed by Stratasys (Source: Stratasys)

Metal 3D printer maker Fabrisonic is using its additive manufacturing technology with NASA’s Jet Propulsion Laboratory (JPL) to produce 3D printed heat exchangers crafted as a single piece for spacecraft. Meanwhile, 3D printer manufacturer 3D Systems has been chosen by aerospace firm Raytheon Technologies to take part in a research project to develop topologically optimized, additively manufactured heat exchangers for the US Army.

In this article, we answer three questions:

- Why use additive manufacturing for heat exchangers?

- What are some of the design considerations that you need to think about when designing heat exchangers for additive manufacturing?

- What are the new opportunities for the design and additive manufacturing of high-performance heat exchangers?

![]() Why Use Additive Manufacturing?

Why Use Additive Manufacturing?

3D printed heat exchanger by FIT AG (Source: FIT AG)

3D printed heat exchanger by FIT AG (Source: FIT AG)

There are a number of reasons metal additive manufacturing, in all of its various technologies, makes for lighter, smaller, more efficient, and more reliable parts.

![]() Heat Exchangers as a Single Piece

Heat Exchangers as a Single Piece

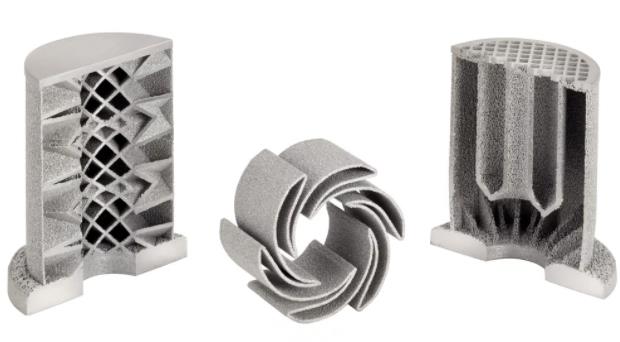

First, AM has the advantage of being able to produce the core and the manifolding as a single part. In other words, no extra steps of forming, assembly, brazing, or welding, so the entire process is faster.

Traditionally manufactured heat exchangers use individual fins or plates that are bonded together. This is a manual process, and if there’s a failure between any of those brazing joints it can lead to failure of the unit. A single-unit part eliminates that risk. Plus, monolithic heat exchangers are significantly lighter weight.

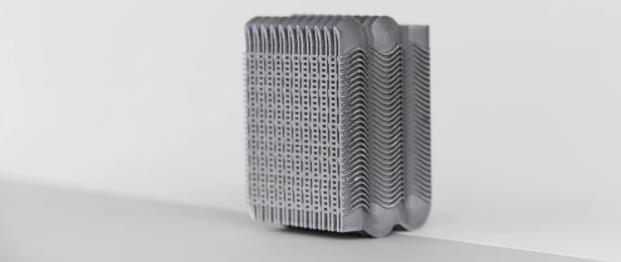

3D printed heat exchanger 3T RPD by EOS with Autodesk (Source: EOS)

3D printed heat exchanger 3T RPD by EOS with Autodesk (Source: EOS)

![]() Smaller & More Efficient

Smaller & More Efficient

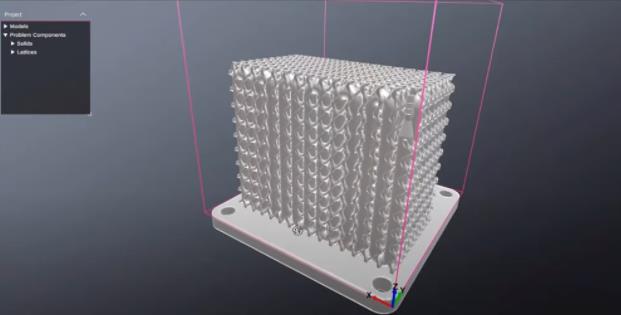

Another advantage is that additive manufacturing can create any size or shape, and the unique shapes and internal features only possible with AM facilitate the miniaturization of these components.

These heat exchanges with much more compact shapes can fit tight space requirements.

Unique and custom, but short-run, production is common in industries like motorsport and aerospace where an engine may have a unique design and tight space for a heat exchanger. AM is great for this because you can design custom packing and manifolding to fit directly into tight volumes.

Plus, with no tooling to consider in the additive manufacturing process, multiple variants can be manufactured simultaneously.

![]() Higher Internal Surface

Higher Internal Surface

Extremely thin-walled internal core lattices increase the surface area and efficiency of heat exchangers. Metal additive manufacturing processes, such as laser powder bed fusion, have the ability to produce walls of 0.1 millimeters of thickness or less. This is not as thin as some traditional manufacturing methods, but AM’s other features make up for this to create a final product that’s still lighter and smaller.

Creating thin walls in AM isn’t without its challenges and often requires R&D on the process parameters to produce these thin-walled structures, but they are ideal for heat exchangers.

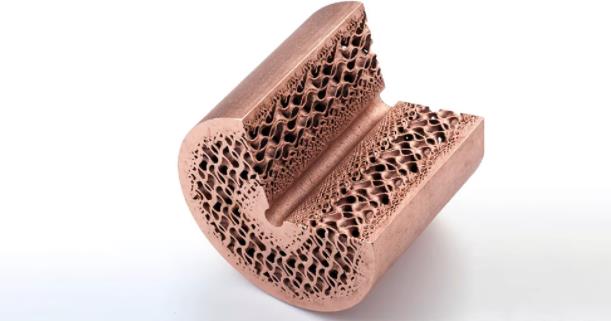

3D printed copper heat exchanger designed by Hyperganic and printed by Heraeus (Source: Hyperganic)

3D printed copper heat exchanger designed by Hyperganic and printed by Heraeus (Source: Hyperganic)

![]() Made in Copper, Inconel, Etc.

Made in Copper, Inconel, Etc.

AM can produce heat exchangers out of a wide range of materials ranging from aluminum alloys all the way up to high-temperature alloys, such as Inconel 718 and Inconel 625. Other materials, such as copper and copper alloys, are also used for additively manufactured heat exchangers for the high conductivity of these materials, which makes them ideal for heat transfer applications. Multi-material heat exchangers are also possible.

![]() New Opportunities in the Design

New Opportunities in the Design

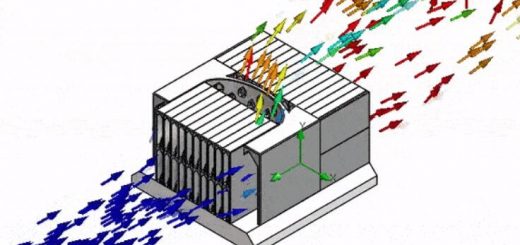

3D printed heat sinks designed with nTopology for use in electronics (Source: nTopology)

3D printed heat sinks designed with nTopology for use in electronics (Source: nTopology)

The design of these complex parts has traditionally been challenging because heat transfer is governed by the physics of conduction, convection, and radiation.

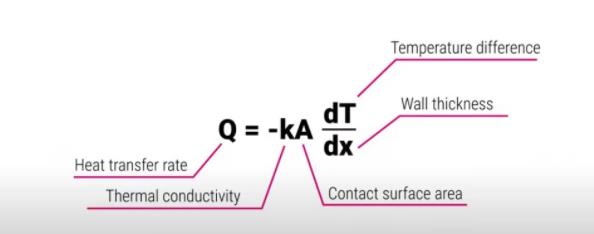

However, if we simplify this heat transfer down into just one element, the conductivity, we can see that the heat transfer is governed by the following equation:

We can see that the heat transfer rate is governed by a number of different aspects.

First, consider thermal conductivity (k). This is normally governed by the material selection, so it may seem logical to use the material with the highest thermal conductivity. However, when designing heat exchangers for endless applications, there are normally conflicting specification elements to consider. Thermal conductivity of the material is therefore important, but, also consider strength, the density of the material, and the melting point. This helps to find the optimum material for the part’s design.

Next, we look at the service area (A), which should be maximized to better transfer the heat.

The equation also shows us that the smaller the wall thickness (dx), the better the conductivity across the wall. Therefore when it comes to designing heat exchangers, the wall thickness is another area where additive manufacturing shines.

The minimum wall thickness for additive manufacturing for laser powder bed fusion (LPBF), for example, is around 0.5 millimeters, but, with careful printer parameter optimization, we can get wall thickness down to much lower than this.

![]() Lattice Internal Structures

Lattice Internal Structures

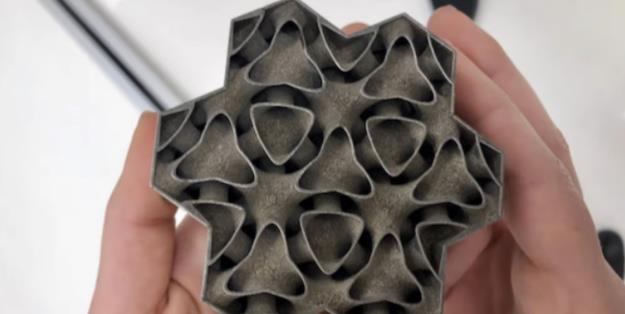

It is popular to leverage lattice structures for heat exchangers because they increase the surface area element to the above equation.

A popular type of lattice for this use case is a triply periodic minimal surface (TPMS) lattice that can split the unit into multiple domains.

Gen3D software in the design of heat exchangers (Source: Gen3D)

Gen3D software in the design of heat exchangers (Source: Gen3D)

Generative design software for additive manufacturing (like ours at Gen3D) can create these TPMS lattices to increase the surface area. By changing the cell size and the density of the lattice within the software, you can tune the parameters of your heat exchanger and optimize the flow design to reduce pressure drop and improve system efficiency. The balance between surface area and pressure drop is a constant balance that heat exchanger designers are facing every day.

Talking about pressure drop brings us to a few more challenges we face at the CAD stage when defining large numbers of thin-walled surfaces.

As we move through the design journey, simulating how these heat transfer surfaces will work can be a challenge. The work of slicing the models before they can go into the CAD simulation software can be data-intensive.

When you get to the printing stage, thin-walled structures can be a risky process that requires careful machine optimization.

The biggest challenge is often at the verification and testing stage where you have to ensure that all the powder has been removed from the internal channels and all the internal walls have been created perfectly. There’s a number of non-destructive testing techniques such as resonance testing to check for powder or CT scanning to check the integrity of the structure.

![]() Additively Manufactured Heat Exchanger Gallery

Additively Manufactured Heat Exchanger Gallery

3D printed heat exchangers by Conflux and Velo3D (Source: Conflux, Velo3D)

3D printed heat exchangers by Conflux and Velo3D (Source: Conflux, Velo3D)

Additive manufacturing has revolutionized the design of heat exchangers. There’s a growing number of patented designs and we’ve only scratched the surface of the benefits additive manufacturing can bring to this one application alone. Yet, hurdles remain, no doubt, in wall thickness, printer speed, verification techniques, and creation and implementation of specific standards.

In addition to the parts already pictured, below are more that illustrate the vast potential of AM. One in particular that we at Gen3D are excited about is a project with 3D printer manufacturer Aerosint where we collaborated to produce multi-material heat exchanger. Areosint makes a multi-material laser powder bed fusion printer that was used to create a single-piece combining high conductive CuCrZr (copper alloy) on the inside surface and high strength steel on the outside.

This copper and steel monolithic 3D printed heat exchanger is one example of what we might see in future additive manufacturing heat exchangers. (Source: Gen3D)

This copper and steel monolithic 3D printed heat exchanger is one example of what we might see in future additive manufacturing heat exchangers. (Source: Gen3D)

3D printed heat exchanger by 3D Systems (Source: 3D Systems)

3D printed heat exchanger by 3D Systems (Source: 3D Systems)

Heat exchangers 3D printed by Mott Corporation (Source: Mott)

Heat exchangers 3D printed by Mott Corporation (Source: Mott)

A 3D printed heat exchanger prototype by GE Research called UPHEAT (Ultra Performance Heat Exchanger enabled by Additive Technology). (Source: GE Research)

A 3D printed heat exchanger prototype by GE Research called UPHEAT (Ultra Performance Heat Exchanger enabled by Additive Technology). (Source: GE Research)

Source: ALL3DP

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments