Markforged Launches H13 Tool Steel For High-Strength, High-Temp Tooling Applications

Markforged, the Boston-area 3D printer company transforming manufacturing, today announced the launch of H13 tool steel for the Metal X, the world’s leading desktop-sized metal printer with over 150 systems shipped since March 2018. The expansion into H13 will enable customers to print parts in high-strength, high-temperature applications such as metal forming tools, dies and punches, and hardened inserts for fixtures, and even injection molds with conformal cooling channels.

Interior of a hardened nozzle printed out of H13 on the Metal X, showcasing printed threads. Source: Markforged

Interior of a hardened nozzle printed out of H13 on the Metal X, showcasing printed threads. Source: Markforged

“We designed the Metal X system to change the way things are made, and the launch of H13 is the next step down that path,” said Jon Reilly, Markforged VP of product. “For manufacturers of high-volume plastic parts this is a game changer, significantly accelerating the speed at which they can bring new products to market.”

H13 is a hot-work tool steel, meaning that it retains high strength at elevated temperatures, and is known for exhibiting excellent red hardness, resistance to thermal fatigue, high toughness, ductility, good abrasion resistance, and excellent through-hardenability. Because H13 can now be 3D printed, manufacturing professionals can begin to print parts with unique and complex geometries, something that traditionally would be very expensive and difficult to do. For example, printing an H13 injection mold that features conformal cooling channels would more effectively move heat away from the mold cavity and provide more uniform cooling, leading to less part-warp, shorter cycle times and higher throughput, and ultimately, lower operational costs.

Exterior of a hardened nozzle printed out of H13, straight out of the sinter, no post-processing.Source: Markforged

Exterior of a hardened nozzle printed out of H13, straight out of the sinter, no post-processing.Source: Markforged

Since 1982, San Francisco Bay Area-based Grant Engineering has been creating high-quality parts from injection-molded plastics, producing millions of parts per year for their biotech, high tech, and consumer product industry customers. Grant is an early adopter of the Metal X printing system who also utilizes the Mark 2 for printing end-of-arm tooling and fixtures. Since they received their Metal X system, the company has been printing 17-4 stainless steel injection molds successfully, with minimal post-processing. Grant Engineering now hopes to further reduce their iteration time and cost for injection molds printed in H13.

“Injection molding is the core of what we do,” said Randy Grant, co-founder and co-owner of Grant Engineering. “Much like the robots and automation we’ve already introduced into our workflow, we see 3D printing – especially the Metal X – as a way to keep us hyper-competitive on cost and turnaround time while still delivering the precision and quality we’re known for. Being able to 3D print H13 should enable a lot of innovation with injection molding, we can’t wait.”

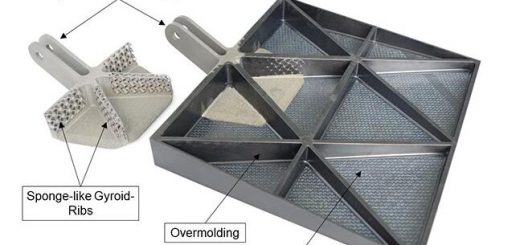

A selection of parts printed in H13 including wear-resistant inserts for fixtures, punch tooling, press brake fingers and a selection of nozzles.Source: Markforged

A selection of parts printed in H13 including wear-resistant inserts for fixtures, punch tooling, press brake fingers and a selection of nozzles.Source: Markforged

H13 tool steel – also known as EN 1.2344 and SKD61 in Germany and Japan, respectively – is bookable beginning December 12, 2018, at 229.99 USD per 1kg spool, and will ship no later than March of 2019. This is just the first of several future materials planned for the Metal X, including A2 and D2 tool steel, stainless steel 316L, Inconel, and Titanium.

Source: Markfoged

Recent Comments