Premium AEROTEC Demonstrates Hybrid CFRP-AM Metal Design for Future Lightweight Aircraft Structures

Today’s aircraft structures consist of many different materials. For example, the fuselage and wing structure of the Airbus A350XWB is constructed mainly of composites with some metal parts. Here, parts are joined, per classical hybrid design, with bolts and rivets. This design leads to high assembly time, effort and cost. Additionally, the high number of fasteners in this classical hybrid design introduces unnecessary weight, as well as stress concentrations at load introduction points.

Image via CompositesWorld

Image via CompositesWorld

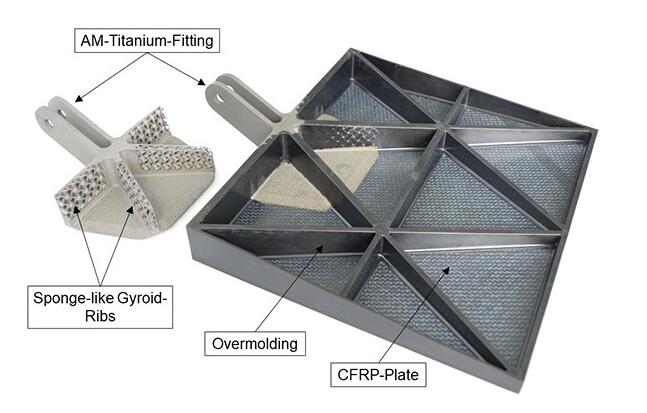

In the project TOAST, Premium AEROTEC (Augsburg, Germany), a Tier 1 supplier of fuselage structures for the A350, has presented completely new methods of joining composites and metals. In this way, the disadvantages of the classical hybrid design with bolts and rivets can be eliminated. Premium AEROTEC developed and manufactured, in less than five months, a demonstrator for an aircraft airbrake-like structure, using a modern hybrid design. It comprised a titanium load introduction fitting made with additive manufacturing (AM) and a carbon fiber-reinforced polymer (CFRP) thermoplastic composite plate, joined using thermoplastic composite overmolding.

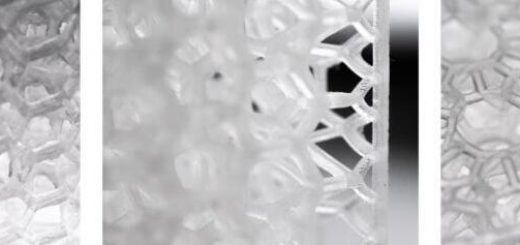

The innovation of this demonstrator is the connection of the different materials without bolts or fasteners. This was only made possible by the use of additive manufacturing and thermoplastic overmolding. The titanium fitting was designed with pins on its lower side and ribs designed with gyroid structures, both readily produced with AM. The AM titanium part and a thermoplastic composite plate were then placed into a thermoforming mold. The two components were pressed together in a thermoforming process with an injection molding step immediately after. During this step, the V-shaped thermoplastic composite ribs were overmolded and pressed into the sponge-like gyroid ribs of the titanium fitting.

The joints in this hybrid demonstrator were realized either by material connection (CFRP – CFRP) or form closure (titanium AM – CFRP). In parallel, structural tests for the determination of the mechanical properties of the joints were performed. These tests showed that the load transfer capabilities were similar to those with rivets and bolts.

The advantages of this modern hybrid design, in comparison to the classical design using mechanicl fasteners, include fast manufacturing and assembly without fasteners, fewer parts are necessary and the process steps for the assembly are shorter and automated. Additionally, the efficiency of the design freedoms exploited by using AM and injection molding lead to weight reductions. This technology can be applied anywhere where loads must be transferred between points and surfaces.

Premium AEROTEC is the first component manufacturer in the world to supply 3D-printed components made out of titanium alloys for serial aircraft production. Premium AEROTEC is a global player in the aviation industry and achieved a turnover of €2 billion in 2018. Its core business is the design and construction of aircraft structures in metal and carbon fiber composite materials. The company has sites in Augsburg, Bremen, Hamburg, Nordenham and Varel in Germany as well as Braşov in Romania. Premium AEROTEC employs around 10,000 people worldwide.

Source: CompositesWorld

Recent Comments