Boeing HorizonX Joins in $12.9M Boost for Digital Alloys’ Metal 3-D Printing Tech

Boeing HorizonX says it’s investing in Digital Alloys, a Massachusetts-based startup specializing in metal additive manufacturing, which adds to more than a dozen companies in Boeing’s tech venture capital portfolio.

The $12.9 million Series B financing round announced today was led by G20 Ventures. Other participants in the round include Lincoln Electric and Khosla Ventures, a prior investor. Boeing HorizonX didn’t announce how much it was putting in, but its investments are typically in the multimillion-dollar range.

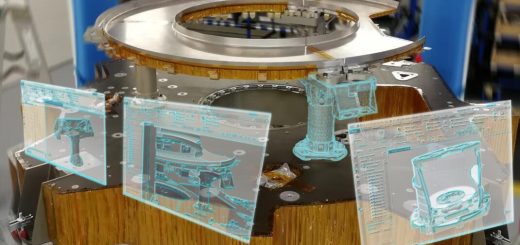

Digital Alloys has developed a technology known as Joule Printing for additive manufacturing of metal components. (Digital Alloys Photo)

Digital Alloys, which was spun out from NVBots last year, is virtually certain to see its metal 3-D printing technology used to build Boeing aerospace parts.

“Our investment in Digital Alloys will help Boeing produce metal structural aerospace parts faster and at higher volume than ever before,” Brian Schettler, managing director of Boeing HorizonX Ventures, said today in a news release. “By investing in companies with emerging additive manufacturing technologies, we aim to strengthen Boeing’s expertise and help accelerate the design and manufacture of 3-D-printed parts to transform production systems and products.”

Digital Alloys says its patented technology avoids the high cost and complexity of powder-based systems, and delivers higher resolution than other wire-based 3-D-printing techniques.

“Our novel Joule Printing process is faster, more cost-effective, and more reliable than other approaches,” Digital Alloys CEO Duncan McCallum said. “Partnering with Boeing will make us a smarter, stronger company. We are committed to enabling Boeing and other leading manufacturers to create valuable new products quickly and at less cost by incorporating metal 3-D printing into their production.”

The process can be used for automotive parts and consumer products as well as for aerospace applications.

Boeing already has more than 60,000 3-D-printed parts flying on space, commercial and defense products. Another company in HorizonX’s portfolio, California-based Morf3D, has been producing 3-D-printed aluminum and titanium components for Boeing satellites and helicopters since that startup was founded in late 2015.

HorizonX Ventures was created last year to serve as Boeing’s channel for outside investments in technologies that are relevant to the company’s interests in aerospace, manufacturing and communication, including autonomous systems, augmented reality and machine learning. Last month, Boeing announced that it’s forming yet another business group known as Boeing NeXt to bring together the technologies supported by HorizonX as well as technologies developed in-house by Boeing and its subsidiaries.

In addition to Digital Alloys and Morf3D, the other companies in the HorizonX Ventures portfolio include:

• Matternet, specializing in urban drone delivery operations.

• Kittyhawk, providing end-to-end software solutions for drone operations.

• Agylstor, which offers ruggedized computational storage systems.

• Reaction Engines, a British venture focusing on hypersonic flight.

• Myriota, an Australian venture focusing on satellite communication services for Internet of Things devices.

• Fortem Technologies for drone radar navigation systems.

• Cuberg for advanced batteries.

• Gamma Alloys, for next-generation aluminum alloys.

• Near Earth Autonomy for autonomous flight control systems.

• C360 for augmented reality and virtual reality used in immersive videos.

• Upskill for augmented-reality solutions for industrial settings.

• SparkCognition for AI tools used with the Internet of Things.

• Zunum Aero for hybrid-electric airplane propulsion.

Source: geekwire

Recent Comments