Fraunhofer IPT Manufactures Super-Lightweight Frame for Experiments in Outer Space

The SpaceX Cargo Dragon space shuttle departed from the Kennedy Space Center in Florida for the International Space Station (ISS) at 2:30 a.m. CET on March 15, 2023. Among others, the shuttle carried an experimental setup that a team of students in the small satellite group KSat e.V. of the University of Stuttgart will use to conduct three experiments. The students were supported by a team from the Fraunhofer Institute for Production Technology IPT in Aachen, who designed and manufactured the super-light and extremely stable support structures for the experiments.

© Fraunhofer IPT

© Fraunhofer IPT

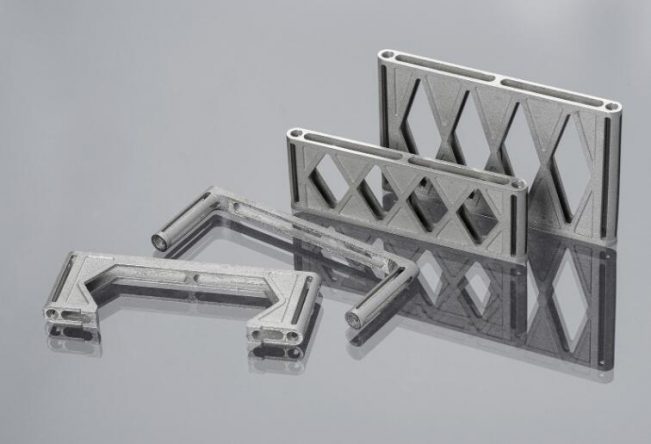

The stainless steel structural components were additively manufactured using laser powder bed fusion (LPBF). The Fraunhofer team was able to produce the complex components quickly and easily thanks to the layer-by-layer structure.

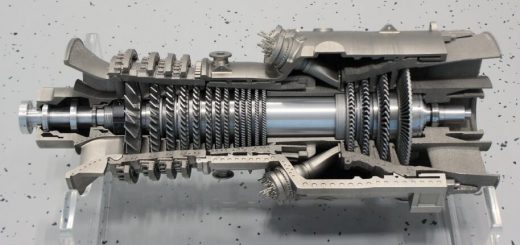

Mechanical components such as ball bearings, pistons or pumps have a limited service life: They wear out over time and have to be replaced. Space engineers face a major problem with such wear parts because they cannot simply be replaced in space. In three experiments, a team of students from KSat e.V. in Stuttgart will test how mechanical components can be optimized through the use of so-called ferrofluids in zero gravity; ferrofluids are liquids containing tiny magnetic particles. The team will also investigate how the ferrofluids can possibly extend the service life of the components.

© Fraunhofer IPT

© Fraunhofer IPT

Stefan Gräfe (right) designed several components. Not only did he adhere to strict specifications, but he also kept the amount of post-processing work as low as possible.

![]() Three experiments in a small space

Three experiments in a small space

In one of the three experiments, a position control system supported by ferrofluids will be tested: The magnetic fluid is directed by external magnetic fields in such a way that torque is generated. The other two experiments involve an electrical switch and a thermal switch, which the ferrofluids open and close an electrical circuit and a thermal circuit.

© KSat e.V. Stuttgart, Foto: Leon Habermalz

© KSat e.V. Stuttgart, Foto: Leon Habermalz

A lot of science in little space: just 10 x 10 x 20 centimeters is the size of the box containing the three experiments.

The ISS astronauts will install the experimental setup in an experimental cabinet on the space station, where it will remain for about four weeks. Space in the cabinet is very limited: Only a space of 10 x 10 x 20 cubic centimeters was allowed for the box containing the experiments. The experimental setups are mounted on aluminum plates that are screwed into the bottom of the box with threaded rods. To stabilize the construction and protect the experiments, special support structures were also necessary.

![]() Strict demands on component design

Strict demands on component design

The students approached the Fraunhofer IPT with a request to design and manufacture four structural components to stabilize and protect the experimental setup. The requirements were strict: The structural components had to be extremely stable in order to withstand the strong vibrations during flight – especially during launch and re-entry into the earth’s atmosphere – and to prevent them from shifting the experiment planes. At the same time, the structure had to be as open as possible to let air circulate and cool the experiments. In addition, the components were not allowed to weigh more than 400 grams in total.

![]() Structural components manufactured additively with minimal post-processing effort

Structural components manufactured additively with minimal post-processing effort

Stefan Gräfe, an additive manufacturing expert at the Fraunhofer IPT, designed several versions of the structural components. Using modeling software, he analyzed the available space and designed components that met all the criteria. He and his team used laser powder bed fusion (LPBF) as the manufacturing process and stainless steel as the material. In LPBF, the powdered material is applied evenly in a very thin layer to a build plate and selectively melted with a directed laser beam. The manufacturing process was an obvious choice because LPBF is the best way to produce both the open areas for air circulation and the hollow structures for weight reduction.

In addition, the researchers pursued another goal: to keep the post-processing effort as low as possible. They designed the components in such a way that they could do without support structures exclusively used for manufacturing, structures that normally have to be cut away afterwards at great expense.

![]() Result significantly better than the specifications

Result significantly better than the specifications

The Fraunhofer team was able to produce the components quickly and easily thanks to the layer-by-layer additive structure of the LPBF process. Subsequently, the components only had to be sawn from the construction plate. In the mechanical workshop of the Fraunhofer IPT, the sawn surfaces were milled off to produce the final height of the components and a smooth surface.

Final measurements revealed that the Fraunhofer team’s strategy worked: The support structures weigh only 141 grams in total, far below the specifications required by the students from Stuttgart. The components also passed the stress tests on their stability, which were run at the German Aerospace Center (DLR) in Cologne. The test setup will now circle the earth for the next few weeks and protect the experiments of the Stuttgart students.

Source: Fraunhofer

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments