LLNL Researchers Develop Method for Real-Time Defect Detection in Metal 3D-Printed Parts

Lawrence Livermore National Laboratory (LLNL) engineers and scientists have developed a method for detecting and predicting strut defects in 3D-printed metal lattice structures during a print through a combination of monitoring, imaging techniques and multi-physics simulations.

The high-strength and low-density properties of metallic lattices have found applications in many fields. During the process of laser powder bed fusion (LBPF) 3D printing, missing struts and defects can occur that affect the mechanical behavior of the printed lattice. To ensure quality, researchers said, scientists typically perform a post-build inspection, which takes time and is not always possible, especially with complex builds. To address this issue, an LLNL team has investigated the ability to monitor build quality in situ to decide, on-the-fly, if the part will satisfy quality requirements.

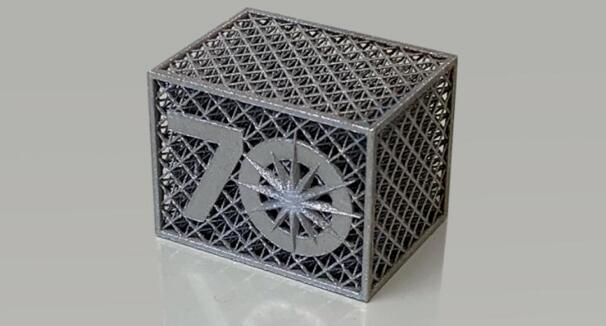

To address the issue of missing struts and strut defects in 3D-printed metallic lattice structures, a Lawrence Livermore National Laboratory team has investigated the ability to monitor build quality during the printing process to decide, on-the-fly, if the part will satisfy quality requirements. Lab 70th anniversary lattice printed by Gabe Guss. Photo by Jean-Baptiste Forien.

To address the issue of missing struts and strut defects in 3D-printed metallic lattice structures, a Lawrence Livermore National Laboratory team has investigated the ability to monitor build quality during the printing process to decide, on-the-fly, if the part will satisfy quality requirements. Lab 70th anniversary lattice printed by Gabe Guss. Photo by Jean-Baptiste Forien.

As described in a paper recently published in Additive Manufacturing Letters, LLNL researchers monitored the printing of a metallic micro-lattice structure using a photodiode, a pyrometer — both of which measure light emitted from the melt pool — and thermal imaging. The team printed normal struts and intentionally defective “half-struts” through the LBPF process, measuring the thermal emissions from the melt pool. The researchers then developed a method to use those thermal emissions to predict defects with high accuracy.

“For the first time, this quality-control process was studied in metallic lattices and we developed a methodology to detect defective struts with a missing bottom part,” said lead author and LLNL staff scientist Jean-Baptiste Forien. “At the moment, we are capable of detecting defects that span multiple layers, but in the future, new methods will be developed to identify defects within a printed layer. This will allow a dynamic reaction and potentially the suppression of the defect before resuming printing of the rest of the build.”

The team developed their defect detection/prediction method based on observations from the test prints, high speed imaging and multi-physics simulations of the LBPF melt pool. By monitoring thermal emission, researchers could predict whether a strut was present or missing with accuracy of more than 94%, validating the mechanisms behind the observed thermal emissions through high-speed thermal and optical imaging, and simulations using the ALE3D multi-physics code.

The researchers said the approach provides “valuable insights” into part quality and reflects the potential of melt pool thermal emission monitoring for identifying defects in LPBF parts.

Co-authors included LLNL scientists and engineers Gabe Guss, Saad Khairallah, William Smith, Philip DePond, Manyalibo “Ibo” Matthews and principal investigator Nick Calta.

Source: LLNL

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments