Additive Manufacturing with Pure Copper: Making the Impossible Possible.

Infinite Flex amazes the AM industry with the world’s first pure copper powder that can be easily processed in with standard SLM systems.

Pure copper is a very popular metal in almost all branches of industry. The main reason for this is it’s high electrical and thermal conductivity. Unfortunately, pure copper cannot be used in additive manufacturing because the coupling of the IR laser radiation hardly works at all with pure copper. The strong reflection of the laser radiation and the high thermal conductivity of pure copper are the primary reason for this.

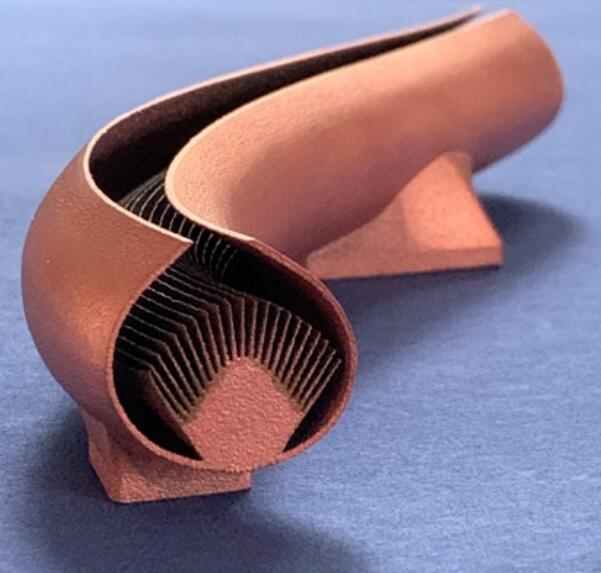

Figure 1: Heat exchanger element (made from INIFINITE POWDER Cu 01)

Figure 1: Heat exchanger element (made from INIFINITE POWDER Cu 01)

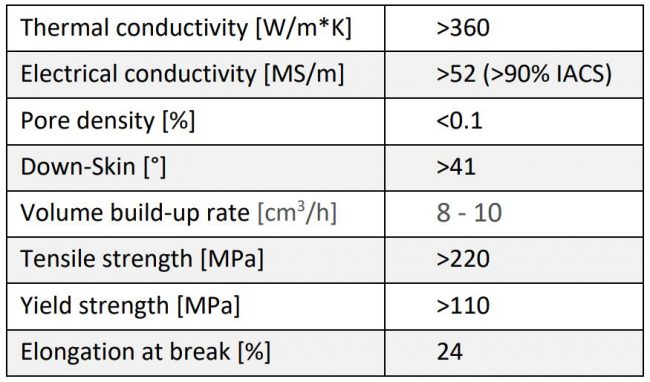

So far, various copper alloys such as CuCrZr or CuNiSiCr have been used; with mediocre results. These copper alloys exhibit significantly lower conductivity properties than pure copper. For example, CuCrZr achieves an electrical conductivity of at best 70% of pure copper and the conductivity of CuNiSiCr is even worse (24 MS/m or around 40% of the value of pure copper).

As a result of this AM-manufactured workpieces with the good electrical and thermal conductivity characteristics of pure copper do not exist, so far. That just has changed with INFINITE POWDER Cu 01. Infinite Flex, a smart materials company located in Neu-Isenburg, Germany, has launched a new pure copper powder that can be easily processed on standard SLM systems. INFINITE POWDER Cu 01 has been successfully tested on the SLM systems from EOS (EOS M290) and Trumpf (TruPrint 1000) and is now commercially available.

The excellent material properties of workpieces and test specimens made from INFINITE POWDER Cu 01 by additive manufacturing are listed in Table 1.

Table 1: INFINITE POWDER Cu 01 (AM -material properties)

Table 1: INFINITE POWDER Cu 01 (AM -material properties)

With these outstanding properties, it is now possible to use the advantages of additive manufacturing for highly conductive copper components. High-end applications such as heat exchangers, induction coils and components in the electronics industry are now becoming reality.

Source: Infinite Flex

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments