Fathom to Provide Evolve’s STEP Additive Manufacturing Technology in North America

Nov 5, 2021, Fathom Digital Manufacturing Company (“Fathom” or “the Company”), an industry leader in on-demand digital manufacturing services, announced that it has entered into a commercialization partnership with Evolve Additive Solutions (“Evolve”). Under the partnership, Fathom will be the first provider of Evolve’s transformative additive manufacturing technology, Selective Thermoplastic Electrophotographic Process (STEP), in North America.

Fathom’s entrenched customer relationships, deep industry expertise, and outcome-focused approach will enable the advancement of additive STEP technology for the production of plastic parts. This is a significant and disruptive innovation for the additive manufacturing industry as it gains ground against traditional manufacturing methods. STEP technology enables the production of thermoplastic parts within hours or days without compromising on quality, throughput, scalability or cost, a significant time advantage over the typical multi-month lead time for traditional injection molding tools and parts. STEP technology is also an environmentally responsible manufacturing process that reduces carbon footprint by eliminating the need for tooling as well as by reducing warehousing and transportation logistics.

Fathom is addressing global supply chain disruptions that are a threat to productivity and revenue generation by fully leveraging over 25 in-house agile manufacturing services across 12 nationwide manufacturing sites which allow the Company’s customers to consolidate and simplify their supply chains. Since the early 2000s, Fathom has been a pioneer of additive manufacturing much like the STEP technology today to propel product innovation forward, and is committed to investing in the latest additive and advanced manufacturing technologies. Additionally, the Evolve SVP™ (Scaled Volume Production) platform delivers throughput that is up to 10 times faster than any other industrial additive printer.

“As a nearly 20-year veteran of this industry, I’ve seen the evolution of additive moving from prototype to low-volume production. I feel strongly that STEP technology will accelerate the adoption of additive manufacturing for scaled volume production of plastic parts,” said Rich Stump, Co-Founder and Chief Commercial Officer of Fathom.

“With these additional investments in the future of digital manufacturing, Fathom is uniquely positioned to serve the comprehensive, end-to-end product development and production needs of the largest and most innovative companies in the world,” said Ryan Martin, CEO of Fathom.

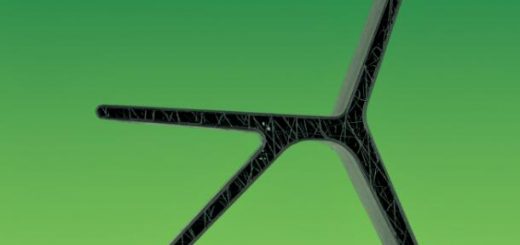

![]() The Evolve Additive Solutions SVP platform

The Evolve Additive Solutions SVP platform

When Evolve CEO and Co-inventor Steve Chillscyzn established Evolve, he spoke to organizations across the globe and asked them, “what would it take for you to seriously consider additive manufacturing for production parts?” Chillscyzn learned that companies wanted the same thermoplastic materials they currently used in injection molding with the same speed, throughput, quality, scalability and the same or better cost as traditional manufacturing. Chillscyzn recognized that there wasn’t a technology solution that met all five of these criteria. Today, these five pillars are the basis of Evolve Additive Solutions’ business model. Evolve has been trusted by large, recognizable international brands such as Stanley Black & Decker and the LEGO Group. Both organizations have invested in Evolve as they believe STEP technology will greatly impact the production capabilities of additive manufacturing and drive Industry 4.0 innovations forward.

STEP technology was developed for speed and scale to offer a manufacturing solution for producing thermoplastic parts. Additive manufacturing, complemented by key advanced traditional manufacturing technologies, offers greater agility and flexibility than traditional manufacturing technologies alone. These technologies are capable of meeting the rigorous demands of customers in the aerospace, automotive, industrial, medical and consumer sectors where products are highly engineered with precise specifications.

Fathom Digital Manufacturing will use STEP technology and its in-house capabilities of over 530 advanced manufacturing systems across plastic and metal additive technologies, CNC machining, injection molding and tooling, precision sheet metal fabrication, and design engineering to help companies bridge critical supply chain gaps. Fathom’s technology-agnostic expertise and robust 450,000 square feet of manufacturing capacity can be the difference in bringing products to market or experiencing a costly line-down situation.

Source: Daily CADCAM

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments