Elementum 3D and SLM Solutions Enable More Powder Choices for Additive Manufacturing Users

For companies looking for more than industry standard powders to create advanced products, the unified approach between SLM Solutions and Elementum 3D enables it. Now, SLM Solutions customers can benefit from the best systems globally while gaining access to previously unavailable powders care of Elementum 3D.

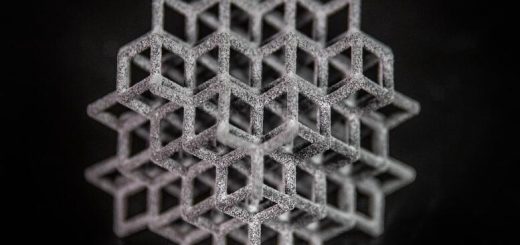

While SLM Solutions already offers superior standard powders, Elementum 3D is an expert in producing advanced metals, ceramics, and composites, setting it apart from other powder developers. “It’s imperative to provide every manufacturer with the option to adopt the disruptive power of additive manufacturing and having the right materials available that will meet their specific needs is the first step,” said Dr. Jacob Nuechterlein, president and founder of Elementum 3D.

Industries such as aerospace, space, automotive, and defense have continued to seek out metal AM as a viable option to advance application innovation. Still, the limited diversity of metal materials, especially aluminum, has traditionally blocked those initiatives. Elementum 3D makes it possible to leap over those material hurdles and clear the way for modernizing application development.

Recently, Elementum 3D implemented an SLM®280 system to test and define new powder development. Need new material development? No problem. Need specific parameter sets? Sure! “It’s great to have partners like Elementum 3D that focuses on meeting the extended needs and desires of our customer base,” said Charlie Grace, Chief Sales Officer at SLM Solutions.

Modern additive manufacturing is defined by a freedom that allows users to push and expand what’s possible. Elementum 3D and SLM Solutions have embraced this mindset through the continuous development of industry machines and materials.

Source: SLM Solutions

Recent Comments