Materialise First to Offer New BASF TPU Material for HP Multi Jet Fusion

Materialise, a global leader in 3D printing solutions, has extended its 3D printing materials offering with the new Ultrasint TPU 01. TPU is a fully-functional, flexible material, making it ideal for resistant and elastic parts. Today, Materialise is the first to make the new material available through its online platforms Materialise OnSite and i.materalise, and through its offline prototyping and manufacturing services.

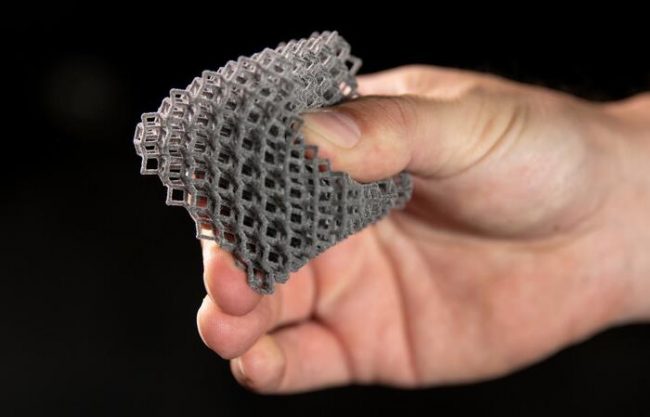

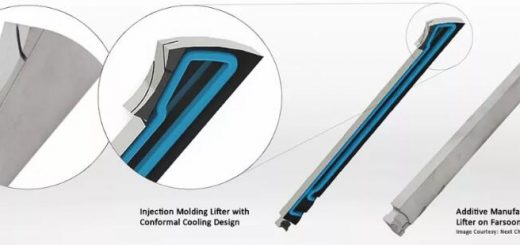

Developed by BASF for HP’s new Jet Fusion 5200 Series, Ultrasint TPU combines smooth surface quality and crisp details with excellent mechanical properties. Its durable elasticity and abrasion resistance make it an ideal material for prototyping and manufacturing applications like air ducts, complex tubing, grippers and seals, but also footwear and other wearables. Thanks to its flexibility, shape recovery and shock absorption qualities, TPU is also perfectly suitable for small series of protective housings and covers. As an early tester of the new 5200 series, Materialise has been closely involved in exploring and developing applications for the new material.

As an early tester of the new 5200 series, Materialise has been closely involved in exploring and developing applications for the new material.

“For nearly three decades Materialise has offered its customers access to the latest and most innovative products, technologies and manufacturing infrastructure”, says Pieter Vos, Marketing Director at Materialise Manufacturing. “Together with our customers we continuously look for new opportunities to create true business value using 3D printing technology. Today’s announcement confirms that ambition.”

Ultrasint TPU is available today at Materialise for design and engineering professionals and the creative community. It replaces the TPU 92A-1 previously offered in Selective Laser Sintering.

Source: Materialise

Recent Comments