A Process for Saving Resources in the Production of Drive Shafts

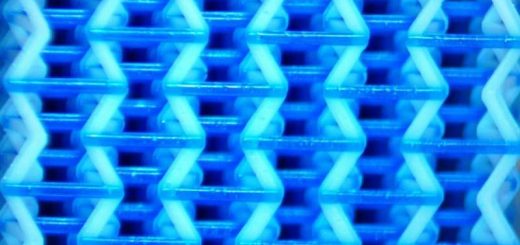

ra EW2C utilizes a movable enclosure, enabling the use of shielding gas for a high process quality.© Fraunhofer IPT

EW2C utilizes a movable enclosure, enabling the use of shielding gas for a high process quality.© Fraunhofer IPT

Express Wire Coil Cladding is a wire-based additive manufacturing process in which a component or structure is built up with a laser by joining metallic materials layer by layer. In contrast to classical laser metal deposition (LMD), the material is not continuously fed into the process as a wire. Instead, the wire first is pushed in the form of spirals to the desired locations on the shaft and then welded there with a high-power laser. Since the wire spirals are placed under tension on the shaft, they cannot slip during the laser process. “Our idea was to change the shaft production more than just cosmetically. We wanted to develop a powerful process that would make producing complex shafts more cost-effective and resource-efficient” says Robin Day, head of the Directed Energy Manufacturing department at the Fraunhofer IPT.

![]() Material mix and rapid buildup of structures

Material mix and rapid buildup of structures

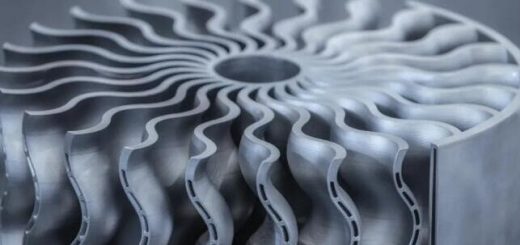

The investigations carried out in recent months give the Fraunhofer scientists grounds for optimism: The tension of the wire spirals improves process stability by a factor of ten compared to conventional wire-based laser metal deposition since unwanted movements of the wire during the welding process are prevented. The researchers were also able to prove that the EW2C process is very well suited for the deposition of thick layers: In a single layer, they were able to apply between 0.5 and 2 millimeters of material, depending on the thickness of the wire. They found that their process can keep up with the cycle times of turning. Indeed, in the test series, the process was able to weld a 25-millimeter high spiral of Inconel 718 with a wire diameter of 1.2 millimeters onto a steel shaft with an outside diameter of 35 millimeters in less than 60 seconds.

The three steps of the EW2C process: positioning, cladding and finishing (from right to left).© Fraunhofer IPT

The three steps of the EW2C process: positioning, cladding and finishing (from right to left).© Fraunhofer IPT

Several millimeters of material could be quickly applied when the steps were repeated. Even different combinations of materials are possible such that the part surface can be technically functionalized and geometrical shapes generated.

![]() Further developments for solid shafts, thin-walled hollow shafts and tubes

Further developments for solid shafts, thin-walled hollow shafts and tubes

In order to improve the new process – for which a patent has already been filed – Robin Day’s team is working on further optimizing process stability and automating the process: Various devices for automated placement of the wire spirals on the shafts are already being tested. “To increase the process speed even further, we are experimenting with enlarging the focal spot geometry and thus irradiating and melting several spiral coils simultaneously”, explains Robin Day. In addition, highly complex volume elements will also be applied to shafts in the future by combining different spiral lengths and other wire materials. To this end, the researchers are testing the suitability of the process for both solid shafts and thin-walled hollow shafts and tubes.

Using integrated sensor technology in the existing machine environment at the institute, the Fraunhofer IPT is also recording various additional data during the process and processing them using Artificial Intelligence (AI). This data will form the basis for modeling and actively controlling EW2C for different materials and process parameters. “With concepts like EW2C it is possible to trigger greater innovations in industries that have developed evolutionary, but not revolutionary, for decades. Additive Manufacturing unlocks great potential, especially in the metal sector. We have only just begun to break new ground”, says Robin Day, enthusiastically.

Source: Fraunhofer IPT

Recent Comments