Innovative Electric Race Car Part Shows Potential for Electron Beam Melting in Automotive

The Manufacturing Technology Centre (MTC), part of the High Value Manufacturing Catapult, supported by Innovate UK, is focused in accelerating the UK’s industrial growth, developing and proving innovative manufacturing processes and technologies together with creating and embedding future skills.

![]() Driving the commercialization of additive across the UK’s manufacturing sector

Driving the commercialization of additive across the UK’s manufacturing sector

Accelerating the adoption of additive manufacturing is a specific focus for the National Centre for Additive Manufacturing Centre (NCAM), part of the MTC. NCAM works with a growing ecosystem of member partners, companies of all sizes and research institutes to challenge the boundaries of additive manufacturing regionally and nationally.

For the past three years, the NCAM’s DRAMA research project has helped build a stronger additive supply chain for the UK’s aerospace sector – an industry which has the largest number of small and medium sized enterprise (SME) companies in Europe.

The automotive sector and motorsports have also been the lifeblood of manufacturing in the West Midlands – one of the UK’s industrial heartlands. For generations the region has been the crux of invention, technology and innovation that has defined motoring and mobility globally.

So, it’s fitting that the NCAM’s Coventry-based team has been using additive technology to continue that innovation legacy and pushing the boundaries of automotive engineering with one of the UK’s leading formula student racing teams.

![]() Electron Beams meets Electrification

Electron Beams meets Electrification

Over the past three years, the MTC has been working with Oxford Brookes Racing (OBR), the formula student racing team at Oxford Brookes University, on various projects. After a long and successful history of combustion entries in the hotly contested formula student competition, OBR was keen to make the shift to all-electric for the 2020 season.

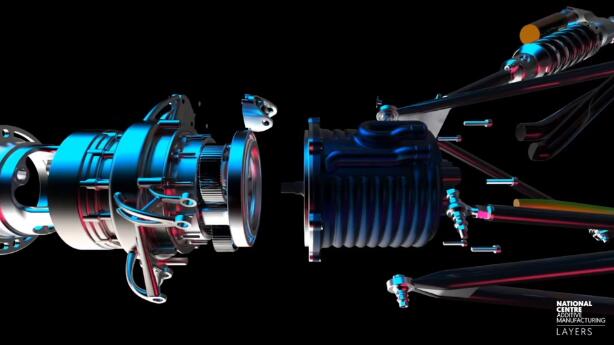

Once again, the OBR team turned to NCAM to explore the potential of additively manufacturing a complex and critical part that connects the suspension link, the brake mounts, the wheel, as well as housing the gearbox to the race car’s electric motor.

The part is based around a 4WD in-hub motor configuration with AMK AC servo motors mated to a compact epicyclic gearbox capable of producing over 300 N-m of torque at each wheel. Energy is supplied from a 600V, 6.6 kW-hr battery pack using lithium cobalt oxide (LCO) pouch cells with a peak output of over 130 kW. All to be managed through an open controls platform, ideal for implementing torque vectoring and advanced vehicle controls to unleash the full performance potential of an electric race car.

Caption: OBR’s complex part produced in Ti-64Al-4V on an Arcam EBM Q20plus. Image credit: Oxford Brookes Racing

Caption: OBR’s complex part produced in Ti-64Al-4V on an Arcam EBM Q20plus. Image credit: Oxford Brookes Racing

“Our team was aiming not only to develop a platform to take on the other top Formula Student teams in the world, but to also serve as a test bed for innovation in electric vehicles and controls software. It has also given us an opportunity to be on the forefront of not only performance, but also the industry by gaining both the knowledge and hands-on experience working with electric vehicles,” comments Charles Boileve at Oxford Brookes Racing.

“We’re here to help wherever we can. In fact, the OBR team already had a strong concept and design for additive in mind, which was about 90% there. Our team was able to add our deep additive expertise, offer guidance and add that remaining 10% in order to get the project up and running,” says Ruaridh Mitchinson, product development leader at NCAM.

“The collaboration case study project enabled demonstration of full AM end-to-manufacturing process; from a conception idea to design for AM, manufacture, inspection and post processing machining. The most exciting thing was working closely with MTC design for AM and process engineering experts to fully explore the EBM AM process capability and as well as disseminating the knowledge to Oxford Brookes racing team,” adds Mitchinson.

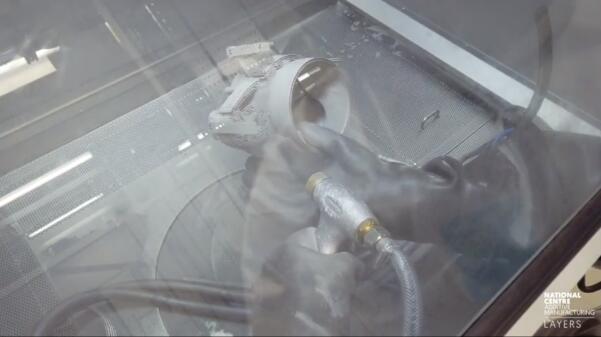

Core to the NCAM team’s expertise is identifying and tailoring the most appropriate technology for a specific application. In the case of the OBR part, electron beam melting (EBM) and a GE Additive Arcam EBM Q20plus were selected from a wide selection of technology at the center’s disposal. Once EBM was selected as the most appropriate, Emmanuel Muzangaza a senior research engineer at NCAM, worked closely with the OBR team on its part.

EBM systems create dimensionally accurate parts quickly and efficiently by utilizing a high-power electron beam. The process takes place in vacuum and at high temperatures, resulting in stress-relieved components with material properties better than cast and comparable to wrought material.

Some of the factors leading to the choice of selecting EBM over other additive technologies for the OBR project included:

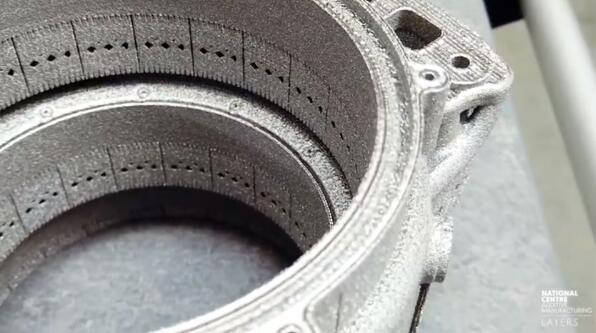

Design freedom that allows for dense nesting of entire build tank and large, bulky parts without swelling and the ability to easily create little to no supports on parts at low costs

High process temperatures mean that parts can be produced with no or minimal residual stress

Cost-Effectiveness. EBM enables the use of reactive and crack-prone materials such as Ti-6Al-4V at low costs and the possibility to reuse powder extracted from the system’s Powder Recovery Station (PRS).

Caption: OBR part produced in Ti-6Al-4V on an Arcam EBM Q20 plus. Image credit: National Center Additive Manufacturing

Caption: OBR part produced in Ti-6Al-4V on an Arcam EBM Q20 plus. Image credit: National Center Additive Manufacturing

Caption: OBR part with supports, prior-to support removal. Image credit: National Center Additive Manufacturing

Caption: OBR part with supports, prior-to support removal. Image credit: National Center Additive Manufacturing

Caption: OBR part with supports removed, prior to post-processing. Image credit: National Center Additive Manufacturing

Caption: OBR part with supports removed, prior to post-processing. Image credit: National Center Additive Manufacturing

Four parts were printed in Ti-6Al-4V, in batches of two per build on the Arcam Q20plus machine at the NCAM facility in Coventry. Each build took around 30 hours.

The additively manufactured part offers several benefits over a conventionally manufactured part in terms of part consolidation, as well as weight and cost efficiencies.

The key outcomes and benefits were:

- Fast iteration and design change implementation throughout the project

- Optimization of component design with thin to think features

- Increased knowledge of the AM process, including understanding the role, requirements and influence of topology optimisation and post-processing

- Transferable capability and knowledge obtained through the case study journey as a result

![]() 2020 Season’s Red Flag

2020 Season’s Red Flag

COVID-19 put paid to the FSUK 2020 season. However earlier in the year, over 80 teams from across the UK still participated in a virtual competition. The OBR20 team placed fifth overall in the Statics category and third overall in Virtual Dynamics category, which had they been scored together – as is done at the real-world event – the team would have placed second overall, and runners up for the third year in a row.

“While we hit a bump in the road this year, we continued to better ourselves as engineers – by pushing ahead and looking forward. The electric revolution is still coming, so we will be striving for perfection as a team, and remain committed to our vision of building a multi-year legacy,” adds Boileve.

Source: GE

Recent Comments