Siemens’ Parasolid Improves 3D Printing and Scanning Workflows with New Tools for Convergent Modeling and Lattice Structures

The latest release of open software technology for geometric modeling from Siemens Digital Industries Software is set to benefit hundreds of software applications and millions of their end-users. The latest improvements in Parasolid® software can help enable engineers to solve the toughest technical challenges and achieve a clear and growing advantage when implementing 3D printing and scanning based workflows.

Vendors of design and manufacturing software applications that license Parasolid can help deliver the benefits of new lattice modeling functionality to their customers.

Vendors of design and manufacturing software applications that license Parasolid can help deliver the benefits of new lattice modeling functionality to their customers.

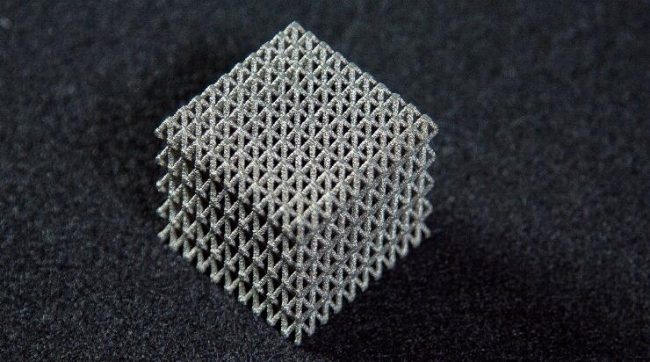

Further advances in Convergent Modeling give engineers greater efficiency in workflows that need to mix facet and B-rep geometry, while new functional foundations have been implemented to support lattice structures. Lattices are comprised of repeating networks of nodes and beams and were extremely difficult to manufacture until the advent of 3D printing. Lattices offer increased strength-to-weight ratio compared with solid material, so engineers can design parts with reduced material requirements and mass, while maintaining the required structural integrity. Additive manufacturing techniques are now bringing the performance benefits of lattice structures into production, driving new requirements for lattice modeling in the design process. Vendors of design and manufacturing software applications that license Parasolid can help deliver the benefits of new lattice modeling functionality to their customers.

The Parasolid geometric modeling kernel is used in Siemens’ own Solid Edge® software and NX™ software and is at the core of the Xcelerator portfolio’s open and flexible ecosystem. Parasolid is also used by over 350 other products including many world-leading CAD/CAM/CAE/AEC software applications.

For more information, please see here.

Source: Siemens

Recent Comments