Chinese Manufacturers Believe Global Adoption of 3D Printing Can Challenge China’s Position as ‘Factory of the World’

Materialise has conducted a survey among Chinese manufacturing companies to gauge their interest and attitude towards 3D printing. The survey* shows that China, the world’s second-largest economy, is focused on prototyping in its adoption of 3D printing and remains doubtful about the readiness of the technology for manufacturing final products. While China is facing increasing competition and making great efforts to advance its production capability, manufacturers are concerned about the country’s role in industrial scale 3D printing. This is illustrated by the fact that half of Chinese manufacturers believe that the global adoption of 3D printing can challenge China’s position as a manufacturing leader.

“For many years, China has been considered to be the factory of the world because of its great efficiency and capability in producing goods and its export-oriented transport infrastructure,” says Stefaan Motte, Vice President and General Manager of the Materialise software division. “Today, China faces increasing competition from both newly emerging economies and highly-industrialized countries in an attempt to take a larger slice of its low-cost manufacturing base.”

![]() Complementary manufacturing technology

Complementary manufacturing technology

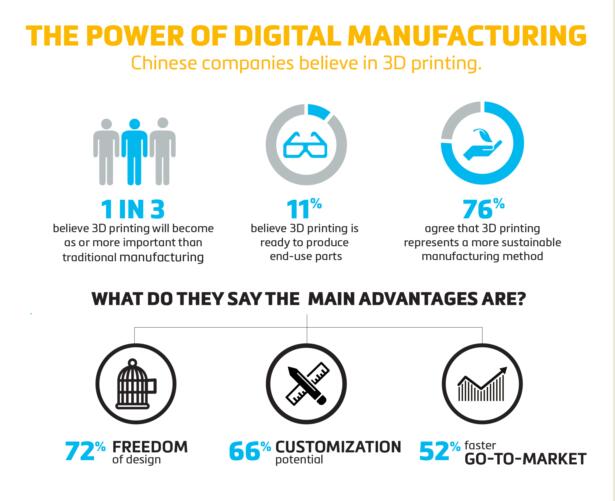

Chinese manufacturers firmly believe in the power of digital manufacturing. Nearly one in three (30%) believes 3D printing will become as important as or more important than traditional manufacturing technologies. 7% even think it will replace traditional manufacturing. Freedom of design is considered the biggest advantage of 3D printing (72%), followed by the possibility to customize products (66%) and the ability to bring products faster to market (51%). Image via Materialise

Image via Materialise

The possibility to print objects in small numbers and to quickly and easily make small design changes, has positioned 3D printing as the ideal rapid prototyping technology. Chinese manufacturers are convinced that the technology is mature enough for the production of visual prototypes (63%) and even functional prototypes (34%), but they are skeptical about 3D printing end-use products. While recent advances in machines, software and materials are fueling the use of 3D printing for the production of final products in sectors such as automotive and aeronautics, only 11% of Chinese manufacturers believe 3D printing is ready to be used for the production of end-use goods.

As an inherently digital and additive production process, 3D printing enables reduced use of materials and creates less waste compared to traditional production methods. When considering the complete end-to-end manufacturing process, including the possibility to produce locally and to customize products, it becomes clear that 3D printing will become increasingly relevant as part of a more sustainable manufacturing process. When asked whether 3D printing represents a more sustainable way to manufacture products, more than three quarters of respondents (76%) agree.

![]() Developing 3D printing capabilities in-house

Developing 3D printing capabilities in-house

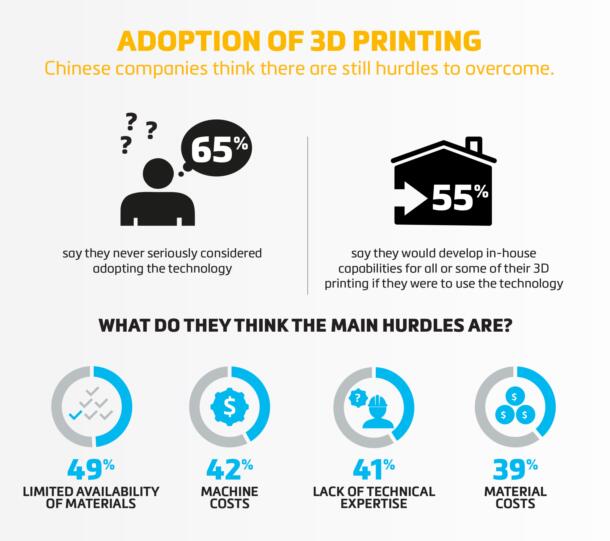

Chinese manufacturers believe there are still a number of hurdles to overcome in order to increase the adoption of 3D printing. For nearly half of the respondents (49%) the main hurdle is the limited availability of usable materials – an area of recent and continued progress. Other inhibitors are cost; more specifically the cost of machines (42%) and the cost of materials (39%).

Image via Materialise

Image via Materialise

A large number of manufacturers also admit that the lack of technical expertise is a major hurdle for adoption (41%). This might explain why only 15% of Chinese manufacturing companies are considering to adopt 3D printing and a majority (65%) have never seriously considered adopting the technology. It may also explain why almost half of them (44%) believe that working with an external 3D printing service provider is the preferred model and only 15% would choose to develop all 3D printing capabilities in-house. However, willingness to develop 3D printing capabilities in-house certainly exists: 40% of respondents opt for a hybrid model, where part of the 3D printing happens in-house and another part is outsourced to an external service provider.

![]() Bold plans, conservative outlook

Bold plans, conservative outlook

Advances in technology and materials are increasing awareness about the unique design and production capabilities offered by 3D printing, fueling global adoption of the technology as a complementary manufacturing technology.

“China still holds a competitive edge in manufacturing,” says Stefaan Motte. “And I believe the country will remain a global manufacturing powerhouse for the foreseeable future. However, China understands that it needs to lift the game on its manufacturing competitiveness to face increasing competition and to move away from being the world’s low-cost workshop. 3D printing plays an important role in this plan.”

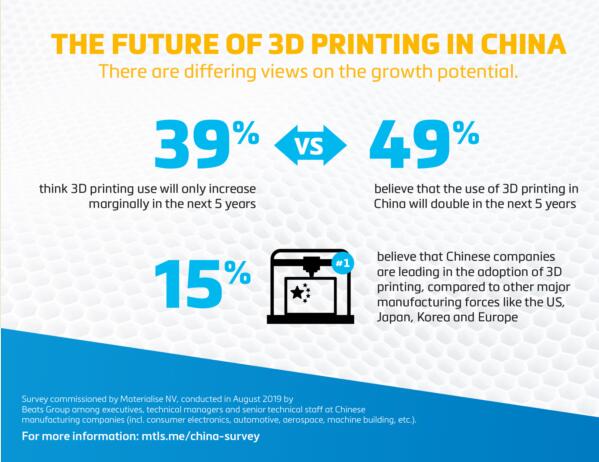

Image via Materialise

Image via Materialise

With Made in China 2025, a strategic government plan issued in 2015, China intends to upgrade its manufacturing competitiveness by investing in advanced technology and preparing the future workforce. 3D printing is regarded as a key enabler for this strategic plan and nearly 70% of manufacturers believe that the adoption of 3D printing is influenced by smart manufacturing initiatives such as Made in China 2025. At the same time, they are on the fence about the growth potential of 3D printing. Almost half (49%) believe that the use of 3D printing in China will double in the next 5 years. On the other hand, 39% think that the use of 3D printing will only increase marginally in the same period.

Chinese manufacturers seem to understand that while they are focusing on rapid prototyping, others are increasingly adopting 3D printing for smart manufacturing. A small minority (15%) believes that Chinese companies are leading in the adoption of 3D printing, compared to other major manufacturing forces like the US, Japan, Korea and Europe. Also, more than 40% believe 3D printing holds the potential to disrupt the global distribution model of goods, as the technology allows for local production, closer to consumers. All of this translates in an uncertain outlook, with half of Chinese manufacturing companies (50%) claiming that the global adoption of 3D printing can challenge China’s position as a manufacturing leader.

![]() Opportunities for growth

Opportunities for growth

The survey indicates that Chinese manufacturers understand the unique design and production advantages offered by digital manufacturing. But as global adoption of the technology increases, they remain focused on 3D printing as a prototyping technology, even though they admit that the global adoption of 3D printing can challenge China’s position as a manufacturing powerhouse.

“Meanwhile, China is modernizing its industrial capability by embracing high-tech intensive manufacturing, as part of its Made in China 2025 initiative, promoting smart production technologies such as 3D printing,” says Motte. “We believe there is an opportunity for industry leaders like Materialise to collaborate with Chinese manufacturers to discover the potential of 3D printing end-use products, to identify meaningful applications and to stimulate adoption by removing some of the remaining hurdles.”

Source: Materialise

Recent Comments