NXT Factory Announces Commercial Launch of QLS350, New Materials Collaboration with Evonik at Formnext 2019

NXT Factory, a pioneer in the development of Quantum Laser Sintering (QLS™) for high speed production of thermoplastic parts, today announced the commercial launch of its QLS350 3D production platform, bringing together new levels of automation and production speed with digital twin predictability and integrated quality sensoring to serial production customers and service providers. To bolster its range of production grade polymers, NXT Factory formed a strategic collaboration with polymer manufacturing leader and innovator Evonik to expand the performance and reach of final-parts applications for customers using the QLS350 system.

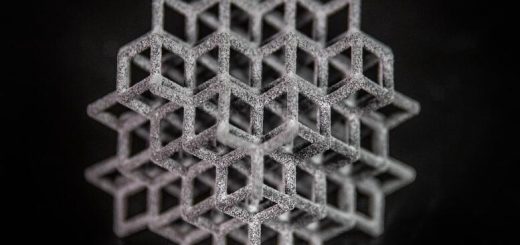

Image via NXT Factory

Image via NXT Factory

NXT Factory plans to demonstrate its QLS350 3D production platform with continuous live printing throughout Formnext at the XponentialWorks booth, B21 – Hall 11 in the Frankfurt Messe. NXT Factory invites industry practitioners, qualified resellers and strategic partners to visit and witness first-hand the power and potential of this new class of production printers. Come see for yourself. Media kit available here.

The QLS350 is based on NXT Factory’s proprietary multi-laser-printing and autonomous print chamber that together enables users to have lights-out 24/7 operations at Industry 4.0 capabilities. Designed for higher operating temperatures and broader sintering windows, the QLS350 can readily process a wide range of supply-chain approved polyamide powders including PA12, and PA6-6. NXT Factory’s technology stack takes Selective Laser Sintering from prototyping parts to economically serialize production performance and volumes.

“We are proud to commercially launch our QLS350 Additive Factory at Formnext and usher in a new category of digital manufacturing,” said Kuba Graczyk, CEO of NXT Factory. “We are deeply committed to helping our customers address their diverse manufacturing needs by being the first to deliver a fully automated high-speed, lights-out industrial system that is powered by our material alliances with Evonik, the recognized pioneer and leader in this field.”

“The new technology of NXT Factory offers further possibilities for our polymer formulations and is a perfect fit for our ready-to-use materials as well as for strategic material development. It is our goal to provide new material systems in cooperation with customers and partners in order to further diversify the market for 3D printing materials and drive it towards serial production,” said Thomas Große-Puppendahl, head of the additive manufacturing innovation and growth at Evonik.

![]() New additive manufacturing cluster (AMC) doubles as customer experience center

New additive manufacturing cluster (AMC) doubles as customer experience center

NXT Factory is building its first customer experience center based on its Additive Manufacturing Cluster (AMC) at the XponentialWorks campus in Ventura, California. The first of its kind, AMC will consist of three QLS350 printers and seven autonomous print chambers. The cluster will be equipped with automated powder handling and management systems consisting of breakout, mixing and refresh. The AMC is designed to help customers accelerate the adoption of QLS across all stages of their additive pursuits; from product design to production.

NXT Factory plans to invest in required infrastructure to showcase the unlimited potential of its QLS platform. The AMC will also help customers simulate what their production would look like upon completion. It will also serve as NXT Factory’s training center for resellers and customers, and field engineers on machine operations, materials and software, providing hands-on training courses.

![]() New Materials from Evonik

New Materials from Evonik

NXT Factory is working collaboratively with Evonik to immediately integrate its leading portfolio of ready-to-use materials as well as developing tailored materials for other mission critical and demanding production use cases. NXT Factory’s QLS system features a detachable print chamber that is integrated onto an autonomous guided vehicle. By detaching the chamber from the printer, cooling and powder management can happen outside the printer, significantly improving productivity and asset utilization. QLS350 is designed to readily process high-temperature materials such as PA6.13, which NXT Factory and Evonik are planning to release in early 2020.

Source: Business Wire

Recent Comments