Essentium Extends Leadership as Additive Manufacturing Market Gives the Nod to Open Ecosystems

Essentium Inc., a innovator in industrial additive manufacturing, announced on Oc.15 a series of business expansion initiatives in response to growing market demand for the company’s platform of industrial-scale additive manufacturing solutions . Together with partners including BASF 3D Printing Solutions and Materialise NV, Essentium is bringing an open ecosystem to the industrial extrusion additive market. This gives customers greater control of their innovation, more choice in materials, and industrial-scale production at ground-breaking economics.

“Additive manufacturing represents a strategic opportunity to help upgrade EMEA’s industrial base and fuel the growth of the manufacturing sector. I’m thrilled to be working with Essentium to help customers realize new opportunities and transform their manufacturing floors.”

The strength of market response and growing pipeline for the Essentium High Speed Extrusion (HSETM) 3D Printing Platform has led Essentium to ramp its printer production in order to meet demand, and to expand its international operations with the appointment of Benoit Valin, General Manager, Asia Pacific, and Cyprien Decouty, Channel Sales Manager, Europe, Middle East, and Africa (EMEA). Prior to joining Essentium, Valin led multiple 3D printing consultancies and was Director of Business Development across Asia for Ultimaker. Decouty was previously Director of Channel Sales for 3D printing manufacturers AON3D and Formlabs in EMEA.

Moving from proof of concept to full production of the Essentium HSE 3D Printer, together with increased material shipments, is fueling month-on-month revenue growth for the company.

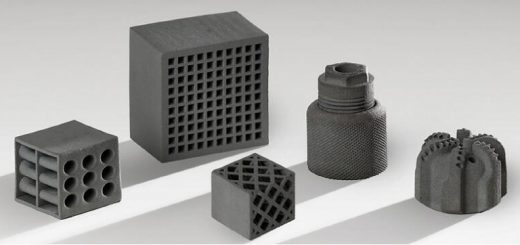

As well as international expansion, the company is doubling down on material innovation. Essentium has introduced seven new materials so far this year including TPU 80A-Z and TPU 90A-FR to service the EMS and aerospace markets. Market demand for Essentium’s HSE 3D Printer and steady increase in materials consumption are clear indications that the open ecosystem approach is addressing unmet needs in the industrial additive market which, until now, has been dominated by closed systems where customers are locked into vendors’ hardware and processes.

Source: Business wire

Recent Comments