Collaboration Brings New Colors to Dow’s Breakthrough 3D-Printable LSR

Designers now have the option to 3D-print silicone rubber parts in color using liquid silicone rubber from Dow and a new dosing system developed by Nexus.

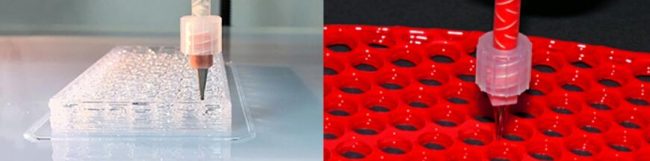

A collaboration between Dow (NYSE: DOW), Nexus Elastomer Systems and German RepRap enables designers to 3D-print colored parts using Dow’s groundbreaking SILASTIC™ 3D 3335 Liquid Silicone Rubber (LSR) and companion color packs from Mesgo Iride Colors.

End-users can now enjoy the benefits of Dow’s 3D-printable LSR in a range of consumer-pleasing colors thanks to this collaboration, which has linked Nexus’s new color dosing system with German RepRap’s liquid additive manufacturing (LAM) 3D printer.

“The collaborative work with Nexus and German RepRap to align the new dosing system with the German RepRap L320 3D printer enabled us to give designers the option of printing colored parts – as well as transparent parts – from this uniquely beneficial material,” said Hans Peter Wolf, research and development manager at Dow.

3D-printable LSR in a range of consumer-pleasing colors

3D-printable LSR in a range of consumer-pleasing colors

SILASTIC™ 3D 3335 Liquid Silicone Rubber is very transparent, enabling users to design and produce parts for applications where clarity and transparency are vital attributes. The final performance is virtually the same, regardless of which color the designer chooses.

Once used primarily for prototyping, 3D printing has entered the realm of production-scale manufacturing. Potential applications include, but are not limited to, mobility and lighting, wearable devices, consumer electronics, and custom footwear.

Source: DOW

Recent Comments