3D Printing Systems Evolutionize Traditional Art Casting

Strassacker, one of the oldest and largest art foundries in Europe, is modernising art casting with 3D printing from voxeljet. The printing technology is used to create investment casting patterns and increases the artists’ freedom of design. Artworks which previously could not be produced using traditional molding techniques can now be printed directly in the form of a casting pattern.

Have you heard of The Bambi Award? The German Media and Television Prize, which is awarded annually to people with visions and for outstanding achievements? The award winners include world stars such as Christoph Waltz, Samuel L. Jackson and Kate Winslet. But far less known is the company that produces the coveted bronze deer: the family owned company Strassacker from Süßen near Stuttgart. Since it was founded in 1919, the company has evolved from the manufacture of pasta machines and everyday objects to the production of numerous precious artworks. The company has made a name for itself especially in the art industry and is now a well-known player. Their customers include world renowned contemporary artists, who rely on the Strassackers’ specialist expertise.

![]() DIGITAL MODEL CREATION AT STRASSACKER

DIGITAL MODEL CREATION AT STRASSACKER

While traditional production methods have characterised the creation of works of art to date, today there are new possibilities for the design of art. One that clearly pushes the boundaries of what is possible is 3D printing. Industrial 3D printing systems can be used to print models made from acrylic glass (PMMA) or casting molds made from silica sand. These are then handled by casters in the same way as traditional wax patterns or sand casting molds. Strassacker recognized the potential of 3D printing early on. For more than 15 years, the company has been working with printed patterns – including printed plastic patterns from voxeljet. During this time, the family business has been able to build up a wealth of experience that it is sharing with its customers.

This means that customers can either send in their completed CAD data sets to Strassacker, where they will be processed in the company’s in-house digital workshop, or customers can approach Strassacker with their project plans and allow the specialists in the 3D modelling department to advise them. “There are hardly any limits to the ideas, but you still need to develop them yourself,” says Peter Mühlhäußer, product line manager at Strassacker. “The same way you have to know where the application of technology makes sense and where it doesn’t. Our technicians, designers and 3D modelling experts are the right people to talk to, in order to define the right technological execution.”

Strassacker can offer its customers both manual and digital manufacturing processes. If required, they can even combine the two together in a hybrid approach.

Examples of this are:

“Wachsende Steine” (“Growing Stones”) by Timm Ulrichs. A stone, in its natural form, was used as the initial model. At Strassacker it was 3D scanned, digitised, scaled to the desired size and then printed in several parts by voxeljet. The larger stones, made from several individually printed PMMA parts, were manually assembled and then prepared for casting by hand. The PMMA models were cast like conventional wax models and then individually patinated by hand. Finally, the bronze casts were airbrushed to look like the natural model and painted by hand.

Another project are the bronze reconstructions of the “Boxer at Rest” and the “Hellenistic Prince” sculptures by Prof. Dr. Vinzenz Brinkmann, which were originally handmade between the 4th and 1st centuries BC and rediscovered on the Quirinal in Rome in 1885.

The original sculptures were 3D-scanned, digitised and printed as PMMA patterns by voxeljet in their service center in Friedberg, Bavaria. Finally, the patterns were cast by Strassacker, chiselled by hand, partially restored and patinated. The finishing touches were made by experts at the Liebieghaus sculpture museum in Frankfurt.

Two other more current examples of the collaboration between Strassacker and voxeljet can be seen in the sculpture “KAS”, an in-house project by artist Peter Simon Mühlhäußer, and the sculpture “Infiniala” by designer Sergej Ehret.

“KAS” stands for “Kinetic Assembly Structure” and reflects the materialisation of a digital thought process. This also served as inspiration for the seat “Infiniala”.

A closer look at the numerous contours of the seat reveals that the lines always form an endless loop.

“KAS” and “Infiniala” show the unique possibilities in the realization of highly complex, digitally created works of art.

The complex nested geometries can only be realized by the use of additive processes, such as binder jetting from voxeljet. It would be impossible to produce these casting models using conventional molding processes.

![]() PRODUCTION OF A 3D PATTERNS AND ITS ADVANTAGES

PRODUCTION OF A 3D PATTERNS AND ITS ADVANTAGES

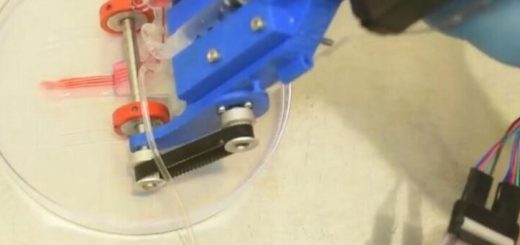

Strassacker uses voxeljet’s 3D printing service to produce, among other things, positive and tooling less patterns for bronze casting. In order to achieve this, they send the 3D data set of an artwork to the voxeljet service center in Friedberg near Augsburg. Here, the CAD data is checked and further uploaded into the VX1000 3D printing system. In the subsequent Binder-Jetting process, the recoater moves over the 1,000 x 600 x 500 millimetre building platform and spreads a 150 micrometre thin layer of the plastic polymethyl methacrylate (PMMA). Then, the print head bonds the PMMA with a binder through polymerisation wherever the artwork is to be created. After each of these two steps, the building platform is lowered by one layer thickness and the recoater and print head process the next layer. This process produces the CAD data layer by layer with a resolution of up to 600 dpi.

Once the print is finished, voxeljet employees remove the model from the job box, remove unbound plastic powder which can be reused 100%, infiltrate the components with wax to further smoothen the surface and send the positive pattern to Strassacker. 3 – 5 days after the placed order the pattern is on-site at Strassacker and ready for further processing.

The casting process at Strassacker can then take its regular course. With a significant advantage: no silicone negative mould has to be created The supplied PMMA pattern can then be immersed directly in ceramic to build a shell and burnt out in the furnace at 700 °C. The PMMA material burns out without leaving any residue, leaving just the ceramic mold, into which the liquid metal can then be poured.

In combination with 3DP, the investment casting process opens up completely new design possibilities. Complex geometries that would have been unthinkable in the past are now possible in the near future.

Added to that, the gating system can also be printed directly. This saves time and delivers consistent casting results.

![]() PRECISION WORK: CHISELLING AND PATINATION

PRECISION WORK: CHISELLING AND PATINATION

Once the casting process has been completed, the chiselling and patinating work begins. A service that Strassacker customers particularly appreciate. In intensive cooperation with the artist, the final appearance of an artwork is created mutually. With custom-made tools, the chisellers precisely carve out intricate shapes and structures. Multi-piece cast parts are joined by a specially developed welding process without any visible welds on the finished work of art. The Bambi also gets its highly polished surface here. Last but not least, the patinater gives the work its colour by anticipating the natural oxidation process using chemical reactions. A high level of craftsmanship and expertise is required to create the subtlest of nuances in colour.

![]() THE FUTURE OF SCULPTING

THE FUTURE OF SCULPTING

Nobody can exactly say, what the future holds for the art of sculpting. But change is clearly audible. There are already a significant number of open-minded artists using new, digital technologies. This change will be of particular benefit when it comes to conceptualising new artistic works. It allows drafts to be drawn up and developed using a computer in cases where manual shaping techniques would be insufficient. Innovative artists are constantly striving to shift boundaries and develop something new. The path they take to achieve their vision is not the priority. Decisive is the transformation into reality. 3D printing gives artists the opportunity to truly innovate. This is why 3D printing has already become firmly established in sculptors’ repertoires and will continue to gain market share.

It could also be conceivable that in the distant future the model pre-acceptance could take place using Virtual Reality glasses. This would allow customers to view the finished artwork in size, colour and shape in three-dimensional space before it actually is fabricated. Peter Mühlhäußer is certain: “”This would be a practical relief that could solve many problems in advance. It continues expanding the dynamic creative dialogue between artist and craftsman.”

Until then, it remains to be seen what new, unique, 3D-printed projects will emerge at Strassacker in the near future with the help of Binder Jetting from voxeljet. On thing is for sure: next time you get to see another Bambi Award celebration, you’ll certainly know, where the Bambi originated.

Source: Voxeljet

Recent Comments