Can 3D Printing Reinvent The Prosthetics Industry?

“The traditional process for creating and fitting a leg prosthetic is long, complex, and uncomfortable for the patient,” says ProsFit Co-Founder and CTO Christopher Hutchison. “It involves taking a plaster cast, creating a mold, and casting resin around it. Often this involves several visits to the prosthetist and results in multiple fittings to get a device that is only marginally effective.”

Hutchison would know. In 2009, he was involved in an accident that required amputation of both legs. His experience led him to co-found ProsFit in 2013.

The mission at ProsFit is to leverage knowledge and technology to enable confident mobility. Said Alan Hutchison, Co-Founder and CEO, “We envision a world where innovation provides limb wearers with a choice of affordable, reliable, and desirable prosthetic products and services.”

ProsFit is headquartered in Sofia, Bulgaria, sometimes called the Silicon Valley of Europe. The company works with medium- and large-size prosthetic clinics to provide custom-made sockets for patients who wear prosthetic limbs.

ProsFit provides a software solution called PandoFit that enables prosthetists to take a 3D scan and create a custom limb socket on screen. Once the design is finalized, ProsFit uses 3D printing to manufacture the socket.

Leg prosthetics typically feature two main elements: the socket is customized for each residual limb, while the other components – such as the foot, knee, and connecting elements – are industrially produced standard catalogue items. ProsFit’s goal is to improve the lives of the world’s more than 20 million amputees by providing them with more comfortable and better-performing prosthetic limbs.

ProsFit’s goal is to improve the lives of the world’s more than 20 million amputees by providing them with more comfortable and better-performing prosthetic limbs.

Sockets were typically made using a plaster mold. First, plaster was cast around the residual limb to create a negative mold, which was then filled with more plaster to create a positive model, which was then rectified manually to adapt it for each individual’s needs. Then, melted plastic was used to create a socket. Once the socket was made, the prosthetist would remove excess material and shape the socket as closely as possible to the contour of the mold. Finally, the patient would visit for a fitting.

Often, several check sockets would be made as the product underwent the refining process to eventually result in a final socket. As a result, fitting a prosthetic could take several weeks. During that time, most patients were forced to use crutches or were confined to a wheelchair, limiting their mobility. The process was also expensive and time consuming.

Prior to working with HP, ProsFit successfully commercialized medically regulated ProsFit Original sockets using fused filament fabrication 3D printing technology. However, the company experienced several challenges, the greatest of which was the consistency of output. ProsFit estimated that two out of every 10 sockets did not pass ProsFit’s rigorous quality assurance process. Furthermore, the surface finish of the end product was often likened to a prototype, and did not meet patients’ expectations.

“In 2014, we manufactured our first socket for Christopher,” says Alan Hutchison. “At the time, it was the first definitive socket ever to be 3D printed. From there, we perfected our business model with the goal of helping millions of other individuals with an emphasis on improved time and cost to comfort.”

At the core of ProsFit’s solution is a cloud-based software called PandoFit. Based on CAD, the software allows prosthetists to easily design lower limb sockets for patients.

The clinician starts by taking a 3D scan of the patient’s limb. This information is uploaded into PandoFit, where the prosthetist can easily modify the design to best fit the patient.

Once the design is reviewed with the patient, a ProsFit socket can be ordered directly through the software. The final product is then shipped to the clinician’s office for the final fitting.

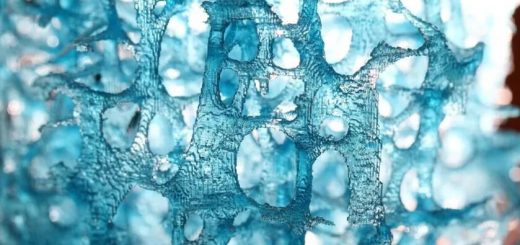

The ProsFit Optimal sockets themselves are manufactured using HP Jet Fusion 3D Printing Solutions and HP 3D High Reusability PA 12 material. Each product is sold as a regulated, custom-made medical device. Prior to launch, the product underwent significant regulatory testing in the European Union (EU), where they are regulated for weight bearing up to 125 kg. The products are also regulated in parts of Asia Pacific, with procedures underway to regulate in other markets in 2019, including the United States.

“Sockets made using HP’s Multi Jet Fusion are flexible and strong, while at the same time more comfortable and natural to walk on,” says Christopher Hutchison. “But beyond that, the fit and finish is what you’d expect from a finished product. The aesthetics are a big deal for patients. A better looking final product improves our customer acceptance.”

By digitizing the process of designing, fitting, and manufacturing a prosthetic socket, ProsFit reduced the time it takes to make and deliver a socket from weeks to days. There are far fewer steps, which helps lower cost and improve convenience for the patient. The final socket can now be made and fitted in only two visits.

Further, because of HP’s Multi Jet Fusion technology, ProsFit can choose how products are manufactured. Technicians can choose the part orientation on the 3D printer that provides the best combination of quality, strength, flexibility, and economics. The resulting product is less costly and more comfortable for the patient.

For clinics and medical centers, ProsFit’s digital solution also has delivered a significant benefit in terms of productivity. They can fit five times the number of patients with the same resources. ProsFit has even been approached by healthcare companies that wish to leverage it to open new prosthetic clinics.

With the consistency of HP Multi Jet Fusion technology, ProsFit can more easily expand their operations. In the EU they are now serving customers in Great Britain, Belgium, France, Germany, and the Netherlands, among others. They’re also supporting clinics in Asia and Australia, and are working with prosthetists to support amputees in war zones in the Middle East. Thanks to the increased strength of sockets made using HP Multi Jet Fusion, they also anticipate acceptance of their product in the U.S. market.

The combination of 3D scanning, software, and 3D printing has enabled ProsFit to deliver on its promise of providing a fully digital solution for the prosthetics industry. They’re making products that are better, faster, and cheaper than were previously considered possible. Every day their knowledge and technologies are improving comfort and convenience for patients around the globe. With the help of HP, ProsFit is accomplishing its mission to enable confident mobility.

Source: Design World

Recent Comments