New Software Takes the 3D Printing Of Medical Models to A New Dimension

Like thousands of people every year, a man at West Kendall Baptist Hospital in Miami was recently diagnosed with heart disease. But unlike most patients, he benefited from doctors having access to an exact 3D replica of his heart to examine before surgery.

Baptist was one of the first hospitals in the world to use GE Healthcare’s 3D-printing software for organs. The software uses data obtained by computed tomography (CT) imaging and converts it into files that can be used to print plastic 3D versions of hearts, livers, kidneys and other organs. “This model of the heart very intuitively and clearly depicts the coronary vessels,” says Dr. Ricardo Cury, director of cardiac imaging at Baptist Hospital. “It is helpful, especially with all the landmarks ahead of time, to facilitate the discussion among the clinical team on procedure planning, the optimal approach and the materials,” he says.

While CT scanning has been around for decades and 3D printing is gaining traction across many industries, the two haven’t previously been able to work easily together. Early on, technologists had to manually generate, convert and compress images into files that could be understood by a 3D printer. “They had to use tools that were not necessarily designed with medical imaging or medical practitioners in mind,” says Amy Deubig, global product marketing manager at GE Healthcare. “The feedback we heard was that the tools weren’t user-friendly, nor were they integrated into their routine workflow.”

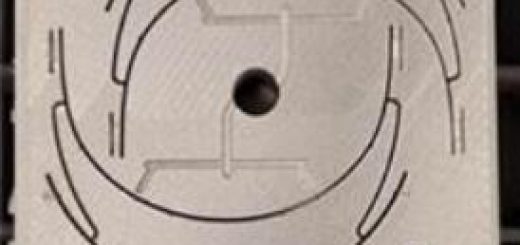

Machines like GE Healthcare’s Revolution CT scanner generate breathtaking images. Now software now allows technicians to convert the pictures into a 3D printed object. Image credit: GE Healthcare.

Machines like GE Healthcare’s Revolution CT scanner generate breathtaking images. Now software now allows technicians to convert the pictures into a 3D printed object. Image credit: GE Healthcare.

GE Healthcare’s 3D-printing software works seamlessly with GE Advantage Workstation systems already working inside hospitals around the world. After a scan, the anatomy is rendered as a 3D image using GE’s Volume Viewer software, a 3D-imaging platform that combines data from sources like CT but also MRI and X-ray. The software then converts the image file generated by the Volume Viewer and within seconds translates it into a file format that can be interpreted by a 3D printer.

“In the past, it would take several days to get the images back” from an outside 3D software processor, Cury says. “The advantage of the new software is it’s in the same workstation where the technologists already do work on 3D images. The steps are a lot quicker and easier.”

More than 100 hospitals around the world have already ordered GE’s 3D organ printing software, which can be used for any type of organ as well as models of bones and muscles. GE says that as more hospitals use the software, it will be easier and quicker for doctors like Cury to share files with each other and have 3D models to use for planning and education prior to procedures.

Source: GE Report

Recent Comments