SLAC Scientists Investigate How Metal 3-D Printing Can Avoid Producing Flawed Parts

Scientists at the Department of Energy’s SLAC National Accelerator Laboratory are using X-ray light to observe and understand how the process of making metal parts using three-dimensional (3-D) printing can leave flaws in the finished product – and discover how those flaws can be prevented. The studies aim to help manufacturers build more reliable parts on the spot – whether in a factory, on a ship or plane, or even remotely in space – and do it more efficiently, without needing to store thousands of extra parts.

The work is taking place at the lab’s Stanford Synchrotron Radiation Lightsource (SSRL) in collaboration with scientists from the DOE’s Lawrence Livermore National Laboratory and Ames Laboratory.

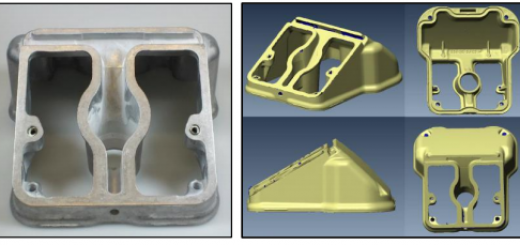

The 3-D printing process, also known as additive manufacturing, builds solid, three-dimensional objects from a computer model by adding material layer by layer. The use of plastics and polymers in 3-D printing has advanced rapidly, but 3-D printing with metals for industrial purposes has been more challenging to sort out.

“With 3-D printing, you can make parts with very complex geometries that are not accessible for casting like regular metal parts,” says SLAC staff scientist Johanna Nelson Weker, who is leading the project. “Theoretically, it can be a quick turnaround – simply design, send, print from a remote location. But we’re not there yet. We still need to figure out all of the parameters involved in making solid, strong parts.”

Metal 3-D printing is being developed for making highly specialized parts for the aerospace, aircraft, automotive and healthcare industries. Right now, companies like General Electric and Boeing that create metal parts with 3-D printing have to put each part and 3-D printer through vigorous qualification. But if the process could be better understood so it reliably prints flawless parts, the researchers said, the need for testing would diminish and the manufacturing cost could come down.

SLAC staff scientist Johanna Nelson Weker, front, leads a study on metal 3-D printing at SLAC’s Stanford Synchrotron Radiation Lightsource with researchers Andrew Kiss and Nick Calta, back. (Dawn Harmer/SLAC)

![]() Pits Among the Layers

Pits Among the Layers

In metal 3-D printing, a thin layer of powdered metal, such as titanium alloys, steel, aluminum alloys, or copper, is distributed on a platform and selectively melted by a high-powered laser beam. Then the platform is lowered, a new layer of metal powder is applied and the process is repeated until the object is fully formed.

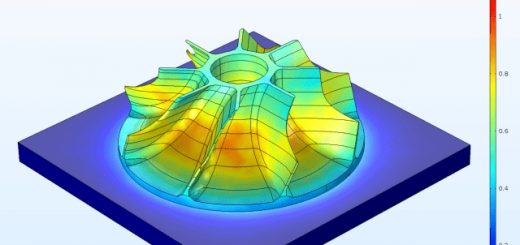

This process often results in the formation of pits, or weak spots, when the metal cools and hardens unevenly while building up the layers. In the SLAC X-ray experiments, scientists are analyzing every aspect of the process – the kind of metal used, the level of heat from the laser, the speed at which the metal heats and cools – to find the best combination for eliminating pits, controlling the microstructure, and manufacturing strong metal parts.

“We are providing the fundamental physics research that will help us identify which aspects of metal 3-D printing are important,” says Chris Tassone, a staff scientist in SSRL’s Materials Science Division. It’s practical information, he says, that could eventually lead to writing recipes for 3-D printer laser settings that manufacturers can use to produce sturdy parts.

![]() Diving in for a Better View

Diving in for a Better View

This video shows the 3-D printing of a metal sample inside an X-ray characterization chamber at Lawrence Livermore National Laboratory before the chamber was dismantled, transported to SLAC and rebuilt. At SLAC the glass windows were replaced with X-ray transparent beryllium windows. The chamber allows researchers to observe metal 3-D printing in real time. (Lawrence Livermore National Laboratory)

Until recently, researchers watched from above as layers were being added to form a part. Because they couldn’t see below the surface of the metal, it was impossible to tell how deeply the laser was melting the layers as each one was applied. They tried imaging the growing layers with thermal radiation, or heat, but this did not give them enough information about what was causing the weak spots. X-rays, however, give researchers an excellent tool to see and record what’s happening inside the part as it’s being built.

The scientists are using two X-ray methods to see what happens during metal 3-D printing. With one type of X-ray light, they create micron-resolution images of what happens as the layers of metal build up. The second method bounces X-rays off the atoms in the material to analyze its atomic structure as it changes from solid to liquid and back to solid form during the melting and cooling process.

Thus far, the group has been looking at lasers hitting layers of metal powder, but they also plan to investigate another approach called “directed energy deposition.” In this process, a laser beam hits and melts metal powder or wire as it is being laid down, allowing creation of more complex geometric forms. This sort of 3-D printing is especially useful in making repairs.

They also want to incorporate a high-speed camera into their experimental setup so they can collect photographs and video of the manufacturing process and correlate what they see with their X-ray data.

This is important to manufacturers and other researchers who use cameras to observe the process but don’t have access to an X-ray synchrotron, Nelson Weker says: “We want people to be able to connect what they see on their cameras with what we are measuring here so they can infer what’s happening below the surface of the growing metal material. We want to put meaning to those signatures.”

Other researchers on the metal 3-D printing project include Kevin Stone, Anthony Fong, Andrew Kiss and Vivek Thampy. SSRL is a DOE Office of Science user facility. The research was funded by the DOE Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office.

Recent Comments