3D Printing Provides Way to Fabricate Probes Used in Cancer Research

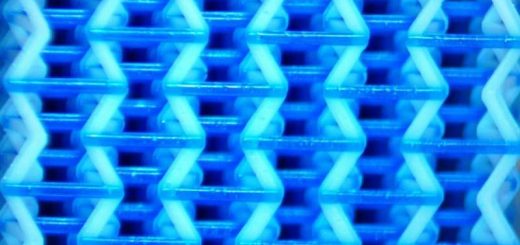

ABU DHABI, Aug. 8, 2018 — Researchers at NYU Abu Dhabi have used a 3D printer to create a functional, integrated and inexpensive microfluidic probe (MFP).

Typically made of glass or silicon, MFPs are tiny scientific tools used to study, process, and manipulate live cell cultures in a controlled environment. However, they cannot be easily produced on demand, and are expensive to make in large quantities.

A microfluidic probe printed in 3D. Cube-shaped and green-colored, this probe is about the size of a ring box, however, the design can be printed in many sizes. Courtesy of NYU Abu Dhabi.

The researchers fabricated their probes in a single step using stereolithographic 3D printing, and benchmarked the performance of the 3D-printed probes against standard MFPs. Their research suggests that 3D printers can provide a sophisticated, highly customizable MFP that works just as effectively as the standard.

“3D printers provide a simple, rapid, and low-cost technique for fabricating MFPs,” said researcher Mohammad Qasaimeh. “All steps, from design to product, can be made in less than a day. Any science lab with a moderate resolution stereolithography printer will be able to fabricate 3D MFPs on demand and use them to process cells reliably.”

The researchers have made their CAD files available for others to try on their own stereolithographic 3D printers.

The research was published in Scientific Reports (doi: 10.1038/s41598-018-29304-x).

Source: photonics.com

Recent Comments