Bowman International manufactures bespoke Rollertrain bearing cages with Multi Jet Fusion

Bowman International is the first company in the UK to use HP’s PA11 nylon material. The company has revealed more details on its investment in HP’s Multi Jet Fusion (MJF) 3D printing technology for the manufacture of bearings, seals and cages.

The company mentioned its acquiring of MJF technology after it announced it had implemented AMFG’s automation software last month.

Supplied by Europac3D, Bowman has purchased the 4200 platform to help reduce on costs and time, while increasing the functionality of end products. It is also the first MJF machine in the UK to print parts in PA11 nylon, which can help deliver parts with greater elasticity, durability and functionality.

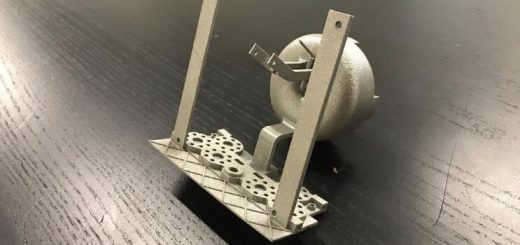

Bowman has used the MJF technology to produce a bespoke ‘Rollertrain’ cage, which boasts an interlocking structure which uses the rolling elements to pin together each section of the cage. Thanks to its design, there is now enough additional space around the cage’s circumference to add two-four more rollers than other bearing cage products on the market, meaning the load can be spread over a higher number of rolling elements, and performance can be enhanced. With an apparent 70% increase in the load bearing capacity of its split bearings and an increased work life of up to 500%, Bowman believes it can now better serve applications which require higher load capacity or extended life expectancy, without having to amend any other part of the bearing assembly.

Prior to purchase, the two companies worked together to test the parts, with Europac demonstrating the capabilities of the polymers compatible with MJF and Bowman suitably impressed with the speeds and accuracy produced. The parts had equal strength in the X, Y and Z directions, which was a welcome result for Bowman, the company tired of its parts suffering deficiencies related to weakness in the Z axis.

“The Rollertrain cage combines the very latest in 3D printing with world-renowned materials science,” commented Jacob Turner, Head of Bowman Additive Production. “Together, this offers OEMs and plant maintenance engineers a split bearing which delivers superior performance and longer product life, alongside simplified mounting and maintenance procedures – not forgetting less vibration and noise during operation.”

“Bowman International’s use of the HP’s Multi Jet Fusion printer is illustrative of how the part production market is being truly revolutionised by 3D printing,” added John Beckett, Managing Director of Europac3D. “The new HP printers are able to accurately mass produce bespoke parts which in turn can cut costs and speed up production times.”

Source: TCT

Recent Comments