New Method enables 3D Printing with Thick Resins

Chinese researchers have developed a new method for 3D printing with high-viscosity liquid resins. Using a linear scanning method in Vat photopolymerization, resins with a viscosity of up to 600,000 cps could be successfully processed. This opens up new possibilities for 3D printing, as previously only low-viscosity resins could be used.

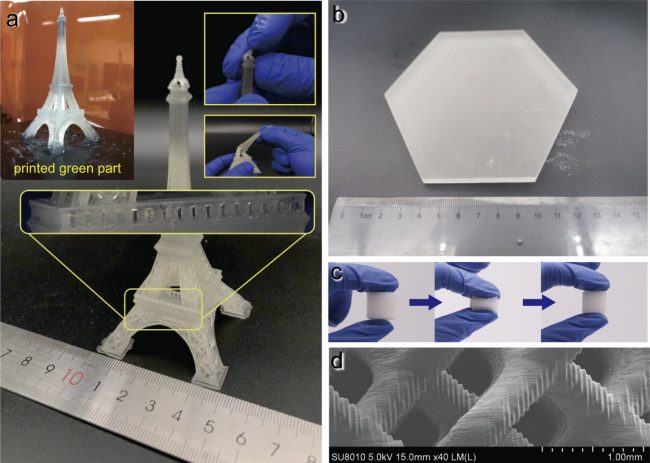

Patterns printed with high viscosity elastomeric UV curable resin. Source: Nature Communications (2023). DOI: 10.1038/s41467-023-39913-4

Patterns printed with high viscosity elastomeric UV curable resin. Source: Nature Communications (2023). DOI: 10.1038/s41467-023-39913-4

In the classic VPP process, the UV-curing resin must have a low viscosity to ensure uniform curing and good adhesion to the printing plate. These requirements limit the mechanical properties of the final product, as reactive thinners often have to be added that alter the original properties of the oligomer.

In the journal Nature Communications, Prof. Wu Lixin and his team from the Fujian Institute of Research on the Structure of Matter presented a new technique called LSVP (Linear Scan-based Vat Photopolymerization). This method uses four rollers to create an isolated pressure area in the resin tank. This allows for simultaneous curing of the resin and release of the finished part, even at a maximum viscosity of 600,000 cps.

The LSVP technique significantly extends the process windows of VPP. It was also found that resins with high CN8888NS content exhibit particularly good mechanical properties, especially when the ACMO content reaches 10% by weight. The results showed an elongation of the material of over 400% and a strength of over 20 MPa.

The research shows that LSVP technology is an efficient method for 3D printing ultra-high viscosity resins without the need for reactive thinners. This development could pave the way for the application of a wider range of oligomers in the 3D printing industry, significantly improving the mechanical properties of the final products.

Source: 3Printing

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments