Custom Color 3D PrintingTurning Designs into Reality with Oqton

Custom Color 3D Printing is a fast-growth start-up based in Chicago, USA, specializing in a range of services including production polymer additive manufacturing and rapid prototyping.

As part of a newly formed joint venture with Mass Persona, it recently expanded into mass production of personalized consumer goods, all in full color. “That’s a key differentiator between what we’re trying to do and what a lot of other people in this space are doing”, explains Kent Mages, Founding President, Custom Color 3D. “There’s a lot of movement in the additive industry, especially lately, towards automated processing of parts. Whereas there’s been little focus on consumer products that end up directly into consumer consumers hands.”

![]() Driving Business Growth with Oqton

Driving Business Growth with Oqton

Custom Color 3D saw an opportunity to follow the market disruption caused by the HP 580 color printer, becoming experts in producing high quality parts and scaling that process up. “We went from being a very small service bureau in 2019 with just two printers to, by the end of that calendar year, needing to upgrade to several printers and getting into mass production of full color personalized consumer goods”, says Mages. Now the company is opening up a new facility with as many as 50 printers connected together by Oqton’s AI powered software platform.

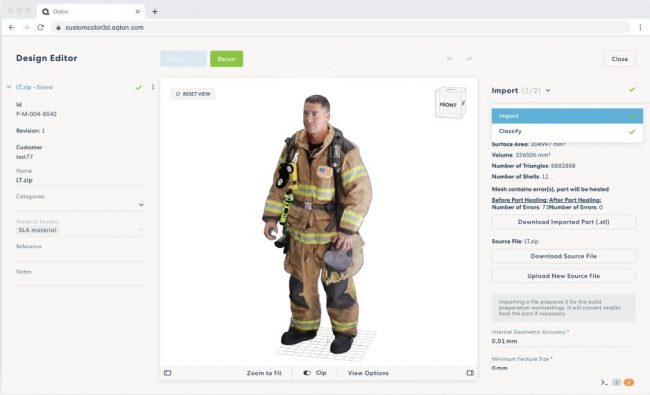

Why Oqton? Because, says Mages, “Colors really matter. Texture, surface, finish – all of those things are really important and none of that gets done unless there’s the data to produce that”. Previously, Custom Color 3D’s biggest challenge was preparing their customer’s part files for the additive manufacturing process. Many customers were experts in 3D graphic design, whether from video games or digital art, but did not have the skillset when it came to additive manufacturing: the part files they provided required significant manually intensive and repetitive preparation steps prior to printing. Similarly, says Mages, “there’s a lot of really talented engineers, industrial designers who do really great work for additive, but don’t really understand how color incorporates into that manufacturing process. So, we had a real challenge in merging those two worlds.”

![]() Bridging the Production Gap

Bridging the Production Gap

That’s where Oqton came in. “Oqton works on systems and software and could really bridge that gap and makes it easier to take a file and to turn that into something that we can print and deliver as a quality product to a customer.”

Oqton works on systems and software and could really bridge that gap and makes it easier to take a file and to turn that into something that we can print

Oqton’s automated nesting capabilities further optimized the build preparation process. “Our work is all software based, but a human being still has to sit at a computer”, says Mages. “At times it’s hours of trying to figure out how to adequately pack parts into a build across multiple printers and efficiently optimize the printers as far as their build volume and production capacity. And that’s one of the first areas that we were able to improve. Oqton really helps by repairing and optimizing files even before we get into the process of tagging them so that they’re able to be printed. They are now ready to go a fraction of the time.”

“The tools that Oqton are building are absolutely going to become a standard for this kind of mass production of color parts”, said Kent Mages, Founding President, Custom Color 3D.

The Oqton AI – powered platform enables AM businesses to scale with less headcount. Mages credits Oqton as playing a big part of his ability to scale.

“The biggest reason that we were excited to work with Oqton is how agile they are and ready to tackle any challenge. I might have started as just one guy with five printers and an eye to increase by ten times that capacity. But to get there, the tools that I needed didn’t exist. Oqton were willing to sit down at the table and talk about what that could look like and what our pain points were and give me an aggressive timeline to be able to meet those demands… I think that the tools that Oqton are building are absolutely going to become a standard for this kind of mass customization production of color parts”, says Mages. ”AI – powered automation is probably the biggest driver, and I fully expect it to trickle down into everything we do.” Oqton will continue to serve as a catalyst to Custom Color 3D’s future growth. One thing Custom Color 3D is clear on: “Oqton will be there as trusted partners for every stage of our growth journey”

Source: oqton

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments