Printed Miniature Loudspeaker with Future Perspective

It has six corners and is about the size of a 1-cent piece: In an additive manufacturing process, miniature loudspeakers can be produced efficiently and cost-effectively as part of piezoelectric, microelectromechanical systems – so-called piezo-MEMS – using a combination of inkjet printing and laser technology. This has been demonstrated by scientists at the Fraunhofer Institute for Laser Technology ILT, the Institute for Materials in Electrical Engineering 2 (IWE2) at RWTH Aachen University and the Fraunhofer Institute for Silicon Technology ISIT. A corresponding demo component was created as part of the recently completed BMBF joint project “Generative Manufacturing of Efficient Piezo-MEMS for Microactuators (GENERATOR)”.

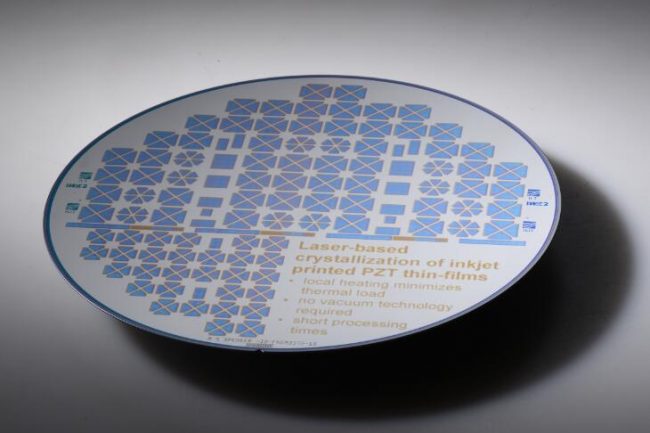

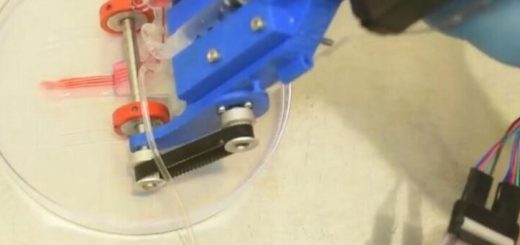

Technical structures and any geometries can be applied to the wafer by means of inkjet printing, and functionalization takes place via laser radiation. The individual loudspeaker elements are then separated and integrated into an electronic environment. © Fraunhofer ILT, Aachen.

Technical structures and any geometries can be applied to the wafer by means of inkjet printing, and functionalization takes place via laser radiation. The individual loudspeaker elements are then separated and integrated into an electronic environment. © Fraunhofer ILT, Aachen.

Piezo-MEMS are true technical all-rounders, because the ultra-thin piezoelectric layers fulfill either actuator or sensory functions: They either expand when an electric field is applied or they convert mechanical motion into electrical voltage. Accordingly, they are in demand in communications or medical technology, for example, as sensors or actuators in pumps, valves or loudspeakers – in each case in miniature format. The thin films are usually made of lead zirconate titanate (PZT), currently the most powerful piezoelectric functional ceramic. Preferably, piezoelectric layers with a thickness of a few μm are used, which can be structured very precisely by etching or direct printing, for example.

![]() Laser-assisted printing processes as an alternative to conventional high-vacuum coating

Laser-assisted printing processes as an alternative to conventional high-vacuum coating

Until now, conventional vacuum and mask-based manufacturing methods have been used in the production of piezo MEMS, but these are very time-consuming and cost-intensive, especially for the production of small batches. As part of the GENERATOR project funded by the German Federal Ministry of Education and Research (BMBF), the Fraunhofer ILT, together with the Fraunhofer ISIT and the IWE2 of RWTH Aachen University, therefore developed a process combination of digital inkjet printing and laser crystallization as a favorable alternative: After the application of PZT special ink to 8″ silicon wafers, crystallization follows by means of laser radiation at local temperatures of over 700°C. The quality is ensured by a temperature-controlled laser beam. Quality is ensured by a temperature-controlled process that limits temperature fluctuations to ± 5°C.

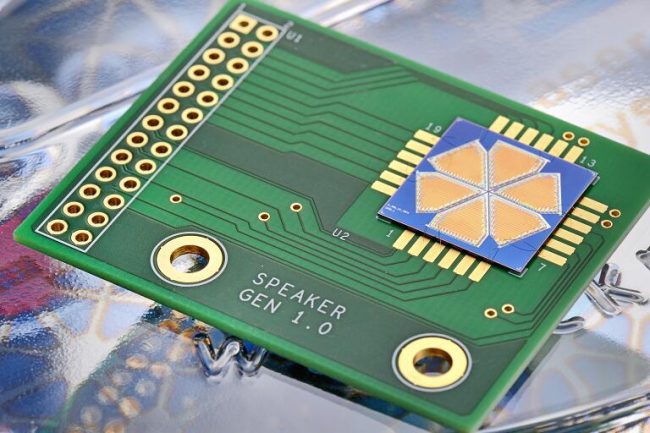

Hexagonal, tiny, inexpensive: The mini loudspeaker from Fraunhofer ILT, Fraunhofer ISIT and IWE2 at RWTH Aachen University proves that microactuators can be produced in seconds and inexpensively using inkjet printers and lasers.© Fraunhofer ILT, Aachen.

Hexagonal, tiny, inexpensive: The mini loudspeaker from Fraunhofer ILT, Fraunhofer ISIT and IWE2 at RWTH Aachen University proves that microactuators can be produced in seconds and inexpensively using inkjet printers and lasers.© Fraunhofer ILT, Aachen.

![]() Multi-material stack trend

Multi-material stack trend

A multilayer actuator with a total layer thickness of 2 to 3 µm is built up from several 20 to 30 nm thin PZT layers. “Initially, we only applied a single layer, but now layer by layer a multi-material stack is being created,” explains ILT scientist Samuel Fink. Alternately, a total of up to 30 layers of functional ceramics and electrodes build up on top of each other to form a micro loudspeaker. Thanks to this design, the actuator is said to offer better performance and higher reproduction quality than conventional actuators. The PZT layers and electrode layers interlock like two very fine combs. The fast laser processing of the layers reduces the processing time per layer, which would otherwise take minutes, to just a few seconds. Instead of the common and very expensive platinum, the scientists use the electrically conductive ceramic lanthanum nickel oxide (LNO) as the electrode material. By dispensing with metallic components, the durability of these purely ceramic multi-material stacks can be significantly increased and material costs reduced at the same time.

If an AC voltage is now applied to this multi-material stack, the PZT layers deform in fractions of a second, thereby exciting the entire stack to vibrate. Since the entire system is only a few µm thick and thus has a very low mass, acoustic signals can be transmitted excellently in this way, especially in the high-frequency range. “The beauty of this manufacturing method is the digitally controllable printing and laser processes, which allow instantaneous design changes of the manufactured layers without additional costs for masks or tools and thus also the production of smaller batches,” says Dr. Christian Vedder, head of the Thin Film Processing group at Fraunhofer ILT.

![]() Opportunity for small and medium-sized enterprises

Opportunity for small and medium-sized enterprises

Conventional systems for manufacturing thin-film electronics cost several million euros and are therefore only worthwhile for large-scale production. For smaller batch sizes, the additive hybrid process becomes interesting, especially if the component consists of several layers like the micro loudspeaker. The process is therefore particularly suitable for small and medium-sized enterprises (SMEs), because the investment in the system technology turns out to be significantly cheaper compared to conventional technology. Fink: “The user needs appropriate printing and laser system technology as well as specially adapted PZT and LNO inks. Even very small job stores could therefore set up small-scale production for microactuators in the future.”

![]() It’s easier: glass instead of silicon

It’s easier: glass instead of silicon

So far, the process has been used for coating silicon substrates. After the multi-stack system has been set up, these substrates still have to undergo relatively complex post-processing in order to produce components that are ready for use. However, the properties of the laser-based manufacturing process mean that other substrates such as ultra-thin glass are also conceivable, which would simplify production even further and open up a wide range of possible applications. “In the course of the project, in addition to process development, we were able to produce very exciting results on the fundamental mechanisms of laser crystallization of ceramics, which take place in the millisecond range. New possibilities are emerging here that are of great interest to me personally and will hopefully soon be transferred to other materials and thus areas of application,” says Fink, looking to the future.

The project on which this report is based was funded by the German Federal Ministry of Education and Research under grant number 03VP02223.

Source: Fraunhofer

Recent Comments