Metallic 3D Printing through Fused Filament Fabrication (FFF)

The fused filament fabrication (FFF) process is widely used in both industrial and private applications. Reasons for this are the simple handling, the wide range of materials, a cost-effective system technology and the uncomplicated maintenance. In expanding the material range to metals, production is very flexible allowing individual parts or small series.

© Fraunhofer IFAM Dresden

© Fraunhofer IFAM Dresden

![]() Current activities and range of services

Current activities and range of services

- Development of new sinterable filament materials for your application (based on all sinterable pure metals or metal alloys)

- Filament testing (diameter variations along the entire filament roll, inhomogeneities, mechanical properties, viscosity)

- 3D printing processing development

- Development of geometry- and material-dependent debinding and sintering processes including in-situ gas phase analysis

- Feasibility studies, comparative studies and process optimization according to customer requirements

- Support in component design, design adaptation and component selection from customer portfolio

- Cost-effectiveness analysis of the entire process chain in the respective application case

- User-specific objective consulting taking into account current AM and PM technologies (Binder Jetting, 3D screen printing, MoldJet, FFF, MIM, 3D gelcasting, LBM, EBM, LMM, Cold Metal Fusion)

![]() Process description

Process description

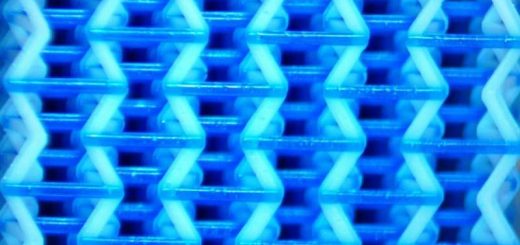

In the metallic Fused Filament Fabrication (FFF) process, the material to be processed is stored on spools as filament (= wire) with a typical diameter of 1.75 mm or 2.85 mm. In this process, the filament consists of metal powder and a polymer mixture that melts at 150 °C – 200 °C. During the process, the filament is fed to a hot nozzle in the so-called print head.

Here, it is melted and extruded through the nozzle opening of 0.25 mm – 1 mm. The extruded filament material is deposited along printing paths according to the target geometry. After a layer has been finished, the build platform can be lowered and the next layer is applied. This process is repeated until the part is complete. The printers have 1, 2 or up to 4 nozzles and can, therefore, print up to 4 different materials in parallel (e.g. component material, release layer, soluble support material).

The printed part is a so-called green part, consisting of the metal powder and the polymer mixture. In a further processing step (debinding) part of the polymer mixture is removed from the component. This is followed by a heat treatment step in which the remaining polymer material is burned out and the component shrinks to 95 – 99 % of the materials relative density.

![]() At a glance

At a glance

- All sinterable materials conceivable: Pure metals (e.g. copper, iron, titanium, molybdenum, tungsten, …) and metal alloys (e.g. stainless steel, tool steel, high-temperature alloys, nickel-based alloys, titanium alloys, copper-based materials, …)

- Structure resolution: 0.5 mm x-y print layer, 0.05 mm z print direction, print accuracy geometry-dependent

- Cost-effective plant technology and simple maintenance -> easy start into AM production

- No handling with loose powder

- No risk of contamination when changing materials

- Typical green part construction rates of 5 – 12 cm³/h per 1000 € printer technology

- Highly customized, parallel production using printer fleet of 2 – 1000+ printers

- Closed cavities and internal channels possible (without powder residues inside)

- Depending on printer: multi-material printing with up to 4 materials possible

- Nearly 100 % material utilization

- Mechanical processing possible in the green state (e.g. surface treatment and CNC machining)

Source: Fraunhofer

Recent Comments