SAE International Issues First Technical Standards for Aerospace Additive Manufacturing

The Aerospace Material Specification committee on Additive Manufacturing (AMS-AM) at SAE International in Warrendale, Pennsylvania, has released its first suite of Aerospace Material Specifications (AMS) additive manufacturing materials and process specifications. The new aerospace technical standards, now available from SAE, support the certification of critical aircraft and spacecraft parts, providing both a framework to protect the integrity of material property data and traceability within the aerospace supply chain.

Federal Aviation Administration (FAA) officials in Washington issued a task request in 2015 asking SAE to form a standards committee to develop aerospace material specifications and related documents to assist them in developing guidance material for additive manufacturing (AM) certification of parts used on aircraft, including “commercial jets that carry passengers over large bodies of water where there is no room for error or inferior quality,” officials say.

“The industry consensus standards that SAE is generating through its AMS-AM Committee greatly facilitate the implementation of additive manufacturing in the aerospace sector. By establishing the appropriate level of rigor and control, the specifications will ensure both quality and consistency in AM products and services,” says Dave Abbott, principal engineer at GE Additive in Mason, Ohio, and AMS-AM committee member.

More than 350 global participants from more than 15 countries representing aircraft, spacecraft, and engine original equipment manufacturers (OEMs), material suppliers, operators, equipment/system suppliers, service providers, regulatory authorities, and defense agencies are active in the AMS-AM committee. Committee members will continue to develop AMS specifications for metal and polymer AM to support the needs of the aerospace industry.

The four aerospace additive manufacturing technical standards are:

AMS7000: Laser-Powder Bed Fusion (L-PBF) Produced Parts, Nickel Alloy, Corrosion and Heat-Resistant, 62Ni – 21.5Cr – 9.0Mo – 3.65Nb Stress Relieved, Hot Isostatic Pressed and Solution Annealed

AMS7001: Nickel Alloy, Corrosion and Heat-Resistant, Powder for Additive Manufacturing, 62Ni – 21.5Cr – 9.0Mo – 3.65Nb

AMS7002: Process Requirements for Production of Metal Powder Feedstock for Use in Additive Manufacturing of Aerospace Parts

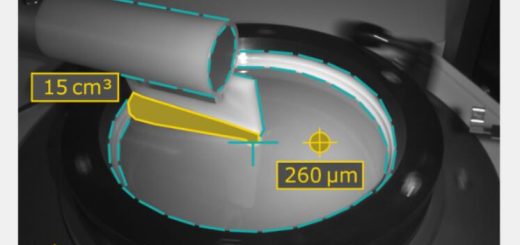

AMS7003: Laser Powder Bed Fusion Process

“Tremendous effort was expended by industry and regulatory stakeholders from North America, Europe and beyond to develop this initial suite of material and process specifications which help address the regulatory authorities’ request for guidance material for this emerging technology,” says David Alexander, director of aerospace standards at SAE International.

“SAE looks forward to assisting with the migration from point design to material qualification by continuing to develop additive manufacturing aerospace material and process specifications,” Alexander adds. “Given that advanced materials and advanced manufacturing are strategic focus areas for SAE International, we are committed to supporting the aerospace industry’s adoption of additive manufacturing technologies.”

Manufacturers across the global aerospace supply chain are increasingly adopting additive manufacturing, also commonly referred to as 3D printing, and realizing the benefits of AM compared to conventional aircraft component manufacturing methods. Among the benefits AM delivers are: reductions in weight and production costs, fewer constraints of the existing supply chain, and the ability to manufacture at high speeds with great accuracy.

Established in July 2015, AMS-AM’s initial standardization project addressed metallic materials and processes for laser powder bed fusion produced nickel-based alloy 625.

The primary objectives of the AMS-AM committee are to:

– Develop Aerospace Material Specifications (AMS) for the procurement of additive precursor and manufactured materials (including metals, plastics, ceramics, composites, and hybrids) made by additive technologies,

– Develop specifications for processing and fabrication of aerospace end products,

– Establish a system to ensure material specifications are controlled and traceable to statistically substantiated data.

Sources: SAE

Recent Comments