Signicast Partners With DDM For Additive Manufacturing

To expand their extensive list of rapid prototyping services, Signicast, a Form Technologies Company, has signed a partnership with DDM to offer the convenience and speed of ceramic 3D printing with the precision of investment casting.

In recent years, Signicast has been expanding its prototyping services to meet the needs and demands of their growing customers. From rapid in-house tooling and CNC machining, direct metal laser sintering, and PMMA and SLA patterns for design validation, Signicast knows that when looking for a fully functional prototype, their customers don’t want to sacrifice quality for time or cost. That’s why Signicast and DDM moved to form a strategic partnership, to deliver the high-quality prototypes customers have come to expect from Signicast, faster.

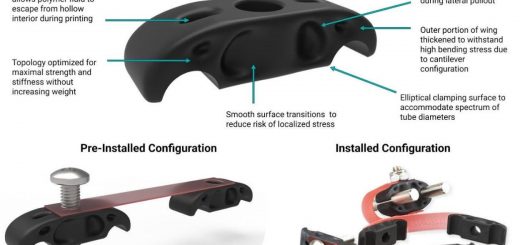

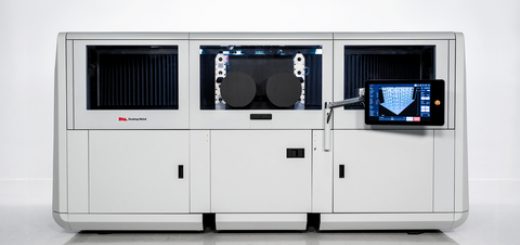

DDM’s LAMP™ Large Area Maskless Photopolymerization ceramic 3D printing technology brings advanced capabilities—including topology optimization and generative designs—for achieving complex components with the convenience and shorter lead times of 3D printing. Partnered with Signicast’s wide selection of material options, state-of-the-art automation technology, and design for manufacturability expertise, customers can expect to receive high-quality prototypes to validate their component designs in a fraction of the conventional time.

These complementary processes give engineers greater design freedom for their components. With the topology optimization and generative design made possible by DDM’s ceramic 3D printing technology, designers can drastically reduce the weight of their components and cast more organic, complex geometries that would otherwise be difficult to produce using conventional methods—all while maintaining full strength. By taking advantage of 3D printing technology to optimize the shape of the design to cut down on surface area, designers are no longer limited by tooling configuration capability.

This technology enables Signicast and DDM customers to create more ergonomic components with less material cost and shorter lead times.

“DDM is extremely proud to join hands with Signicast to modernize investment casting while offering speed, complexity and value to customers. This partnership greatly accelerates the introduction of DDM’s ceramic 3D printing based Digital Foundry™ offering to the market,” said Dr. Suman Das, Founder and CEO of DDM.

Marc Riquelme, President of Signicast, says, “This is a great process to bring to Signicast customers and offers new growth opportunities to all the markets we serve. DDM’s 3D printing technology will bolster our core offering and amplify our footprint in additive manufacturing.”

The partnership between Signicast and DDM is evidence of the exciting advancements in precision casting technologies and opens up new design opportunities for both of their customers. Over time, Signicast expects to transition this technology for full-scale production runs in addition to prototyping.

Source: Signicast

Recent Comments