Guhring UK Creates Specialty Cutting Tools with Markforged Additive Manufacturing

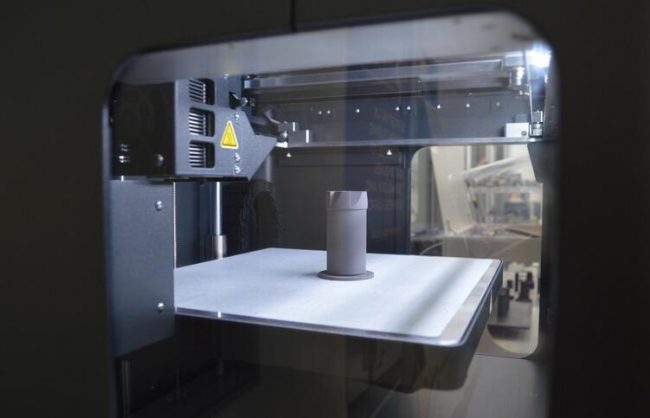

February 5, 2020, Markforged, the leading provider of metal and carbon fiber 3D printers, today announced that Guhring UK has introduced Markforged additive manufacturing into their custom cutting tool line. Utilizing their Metal X 3D printer, Guhring UK has created and put into production an H13 Tool Steel milling cutter with a uniquely-designed infill for increased efficiency. The new tool reduces the weight of the part by 60% and the cost by 75%, and will allow the team to open new revenue streams and better serve their customers.

Image via Markforged

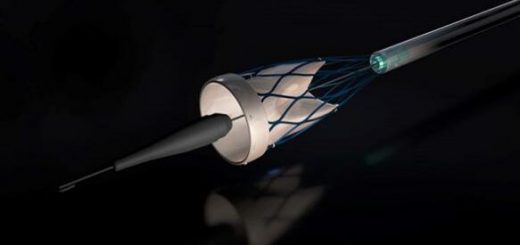

Image via Markforged

“Guhring UK is doing something truly remarkable — they’re using additive to make subtractive processes better,” said Michael Papish, VP of Marketing at Markforged. “This is the first time a company in our space has had a foothold in the specialized and early-stage production tooling market. And instead of just replacing their traditional cutting tool, Guhring has used our additive technology to optimize the weight and interior geometry of the part, thereby creating more efficient tools faster and cheaper.”

Guhring UK is the Birmingham-based subsidiary of cutting tool manufacturer Guhring Group. The company specializes in made-to-order carbide and polycrystalline diamond (PCD) cutting tools it supplies to leading companies like BMW, Jaguar Land Rover, Airbus, and BAE Systems.

Today, Guhring UK has supplied a comprehensive range of production-grade 3D printed metal cutting tool bodies, for milling and special purpose applications and all of which are still in daily use at their clients. Guhring’s own tooling design engineers were extremely impressed with the results. “Within five days, we had printed and sintered a fully functional metal cutter body,” says Alan Pearce, PCD Production Supervisor at Guhring UK. “Using Markforged 3D printers just speeds up everything.”

The 3D printed tool is 60% lighter than its traditional predecessor, which allows for faster tool changes in cycles and a reduction in cycle times. And at a 75% cost savings, this application allows the company to produce more versatile, lightweight tools for its customers at a far lower price.

“The Metal X removes the traditional design constraints of conventional tool manufacturing while providing the best that additive has to offer. The ability to reduce the weight of the part as well as introduce completely new interior features ensures Guhring UK will stay at the cutting edge of tool design,” said Papish.

The Guhring UK team started their journey with additive manufacturing by using a Markforged carbon fiber 3D printer to make custom sample parts and replacement parts for their plant. Integrating the Markforged industrial printing platform into their workflow has completely changed — and sped up — the full manufacturing process for the company. Metal 3D printed tools now give customers a better idea of not only how the tool will look, but also perform.

These benefits have allowed Guhring UK to directly invest back into their business to continue growing and supplying bigger and better products to its customers. The extra time it saved will go into the fabrication of production parts. “With Markforged additive manufacturing, we’re well on the road to being a factory of the future,” says Pearce.

Source: Markforged

Recent Comments