VELO3D Announces Assure™ Quality Assurance and Control System for 3D Metal Printing and Stratasys Direct Manufacturing as First Customer of Assure

VELO3D has announced the release and availability of the VELO3D Assure™ Quality Assurance and Control System for its Sapphire® 3D metal printers. Stratasys Direct Manufacturing, a subsidiary of Stratasys, Ltd. (NASDAQ: SSYS) and one of the largest providers of additive (3D printing) and conventional manufacturing services in North America, is the first customer to implement Assure.

Image 1. VELO3D’s Assure™ quality control dashboard enables engineers to track the quality and progress of Sapphire® machines in real-time. Image via VELO3D.

Assure provides substantiation of part quality needed for volume production. It detects process anomalies, flags them, and highlights the corrective actions required so errors are not repeated. Through real-time, multi-sensor, physics-based detection algorithms, Assure delivers unprecedented traceability of part quality and flags process anomalies as soon as they occur. This decreases variation and provides comprehensive documentation to fast-track printed-part validation.

“Assure is a revolutionary quality-control system, an inherent part of the VELO3D end-to-end manufacturing solution for serial production,” says Benny Buller, founder and CEO of VELO3D. “Assure is part of our vision to provide an integrated solution to produce parts by additive manufacturing with successful outcomes.”

Stratasys Direct began working with VELO3D on Assure testing soon after they acquired a Sapphire printer earlier in the year. Stratasys Direct implemented Assure to identify variations and anomalies in the production of the parts on several builds. Throughout the study, Stratasys Direct accessed Assure’s dashboard and sophisticated algorithms to monitor the integrity of the builds, validate the bulk material density, observe ongoing process metrics, and verify the calibration of the system across multiple production runs. These trials and results confirmed the capabilities of the software, and were documented in a VELO3D/Stratasys Direct co-authored whitepaper (Stratasys Direct Manufacturing Performs Field Validation ofVELO3D Assure™), which was released November 5th, 2019.

“Stratasys Direct has built a culture of continuous improvement that means we are continually setting new standards for our industry on quality,” said Kent Firestone, CEO of Stratasys Direct Manufacturing. “We integrated Assure into our quality control workflow because it produces highly actionable insights. The user interface features intuitive graphs and charts that enable us to see and interpret the vast amount of data collected during builds. This information helps our engineers verify the quality of the build each step of the way, and enables them to make quick decisions in the event of an issue. Assure helps us reduce production variation, improve yields, and circumvent anomalies to ensure consistent additive manufacturing.”

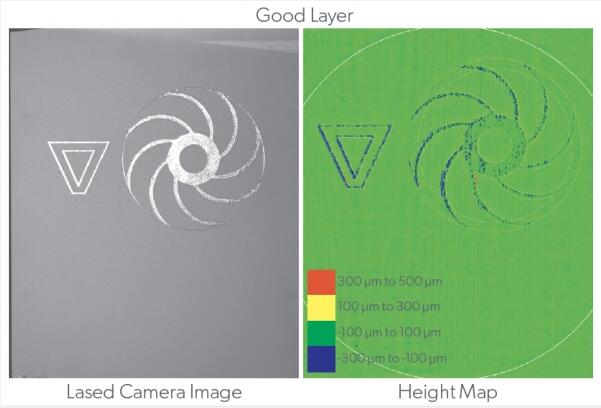

Image 2. Assure provides true z-height quantitative powder bed and part metrology. Note the sections of parts with red lobes indicating metal protruding >300um above the powder bed but still below control limits.Image via VELO3D.

Image 3. Assure provides high correlation between measurement and real world results. The software generates a build report that provides unprecedented traceability for the part manufacturer and the end-use customer. Image via VELO3D.

Image 4. Before and during a build, Assure validates that critical parameters stay within control limits ensuring high quality parts. Image via VELO3D.

Source: VELO3D

Recent Comments