OPTOMET–First Time Right,Software for Parameter Optimization

DMG MORI has developed the software OPTOMET in cooperation with INTECH for controlling the parameters of the powder bed process. It has self-adjusting and learning algorithms that calculate all required parameters of the SLM process in advance within minutes. This means layer thicknesses can be calculated freely, which in turn enables a faster and therefore also more productive build. OPTOMET has a material database that allows customers to use materials from all manufacturers without having to test them in advance. The open system also allows independent expansion of the database using the customer’s own experimental data. OPTOMET is able to adjust parameters in such a way that material properties, such as hardness, porosity and elasticity, can be changed or optimized.

![]() CELOS for optimum workflow in pre- and post-processing

CELOS for optimum workflow in pre- and post-processing

The integral software solution for CAM programming and machine control, CELOS, rounds off the process chains for the LASERTEC SLM series. The coordinated and standardized user interface enables parts to be programmed offline quickly and transferred to the machine – regardless of their complexity. Due to the efficient flow of information and intuitive operation, CELOS ensures an optimum workflow in the pre- and post-processing of additively manufactured parts. As a consequence, the open system of the LASERTEC SLM series enables individual adjustment of all machine settings and process parameters, right through to an extensive choice of material suppliers.

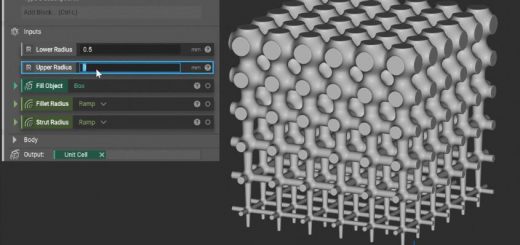

![]() LASERTEC 12 SLM – four-times more accurate than the industry standard

LASERTEC 12 SLM – four-times more accurate than the industry standard

Precision in additive manufacturing depends basically on three parameters, namely minimizing focus diameter, layer thicknesses and powder particle size. DMG MORI has taken exactly these parameters into consideration in the development of the new LASERTEC 12 SLM and has designed a high-precision machine for building the thinnest walls. The top properties and features already familiar from the LASERTEC 30 SLM2nd Generation – the rePLUG powder module, CELOS as an integral software solution, the open system and ergonomic design – also apply without exception to the LASERTEC 12 SLM, making this innovative machine the ideal addition to the DMG MORI portfolio of process chains in ADDITIVE MANUFACTURING.

DMG MORI developed the LASERTEC 12 SLM with a special focus on precision. A small focus diameter of 35µm over the entire build volume enables high-precision creation of the thinnest walls – four-times more accurate than the current industry standard. The thin layers can be built accurately and with exact repeatability thanks to integrated linear scales with a resolution of less than 1μm. An integrated sieving unit prevents larger particles or agglomerates from entering the build chamber immediately before introduction of the powder. In addition, the application of the powder in the build process is carried out safely in an inert gas atmosphere.

Despite its specialization and optimization in the high-precision building of filigree structures, DMG MORI has nevertheless managed to achieve a build volume of 125 ×125 ×200mm – the largest in this accuracy class. The ergonomic construction of the machine in Stealth design also reflects the principle that DMG MORI has been pursuing and optimizing continuously for many years, namely making the machine easy to use and efficient by ensuring better accessibility to all key elements. Furthermore, the LASERTEC 12 SLM is based on the same machine platform as the LASERTEC 30 SLM 2nd Generation, making this new development just as robust while retaining compatibility with both the conventional rePLUG and rePLUG reSEARCH. Rapid material changeover in less than two hours boosts the productivity of the LASERTEC 12 SLM enormously.

DMG MORI has designed the rePLUG reSEARCH especially for the development of materials. In contrast to the conventional rePLUG, this module has bottle-based powder feed suitable for significantly smaller material quantities, instead of the large powder container with a closed powder circuit. This ensures simple cleaning of the system, which brings great time savings and reduces the risk of crosscontamination to a minimum – especially important when trying a variety of materials. Any excess powder is collected in a bottle and can be sieved externally, ready for reuse.

Source: DMG MORI

Recent Comments